Recovery processing method of protein waste water

A technology for the recovery and treatment of protein wastewater, which is applied in the field of recovery and treatment of protein wastewater, to achieve the effects of easy operation, high treatment cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

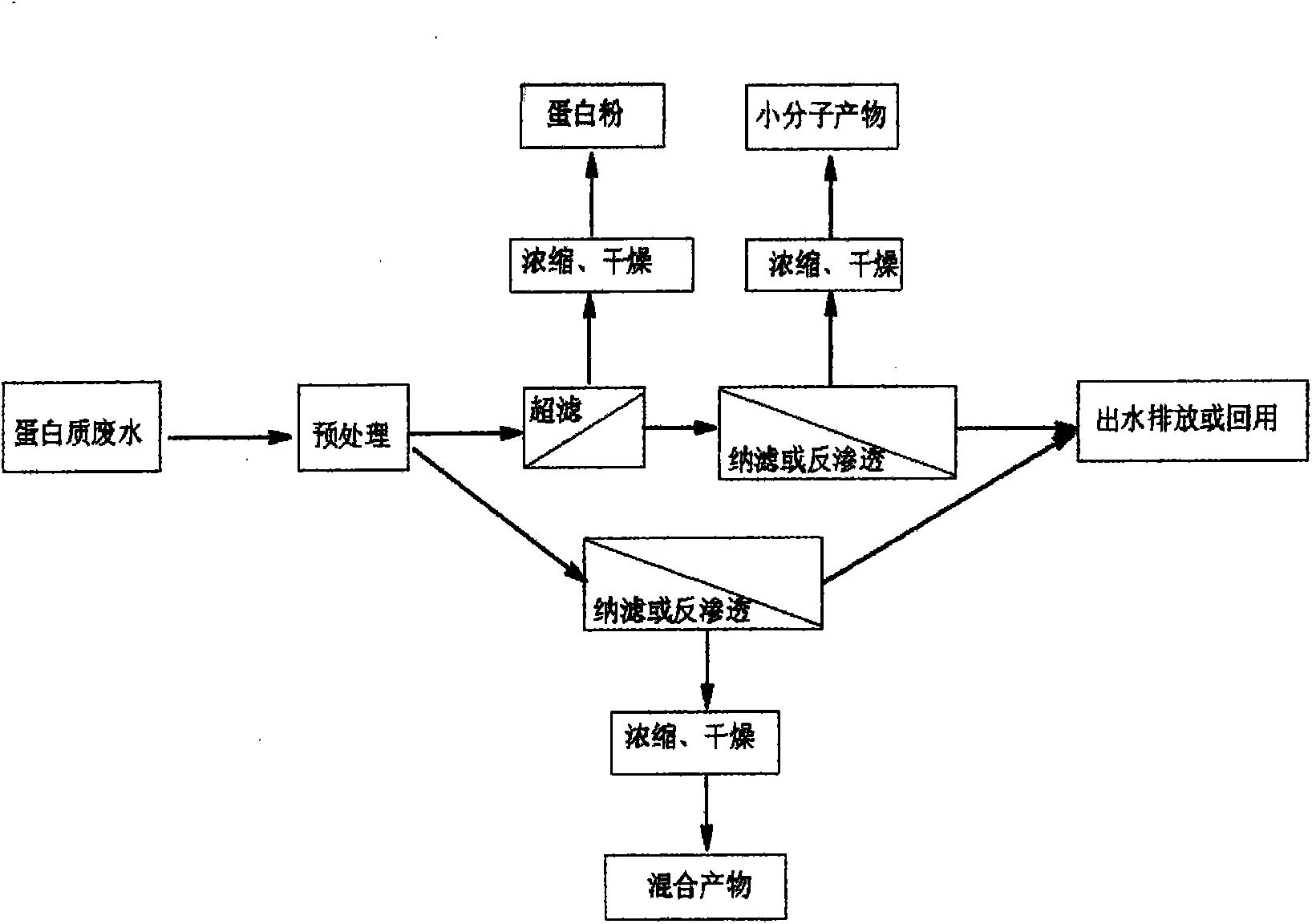

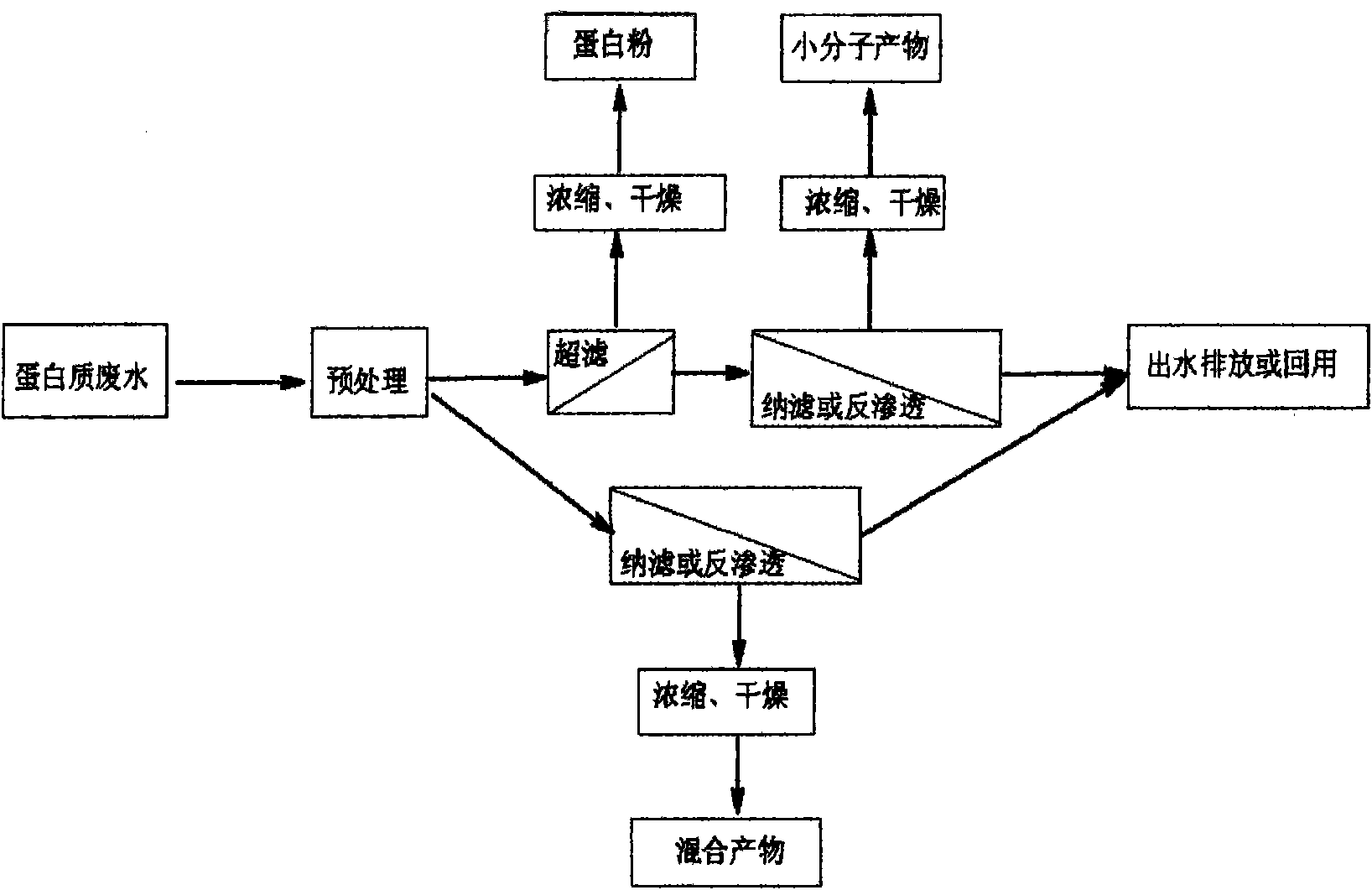

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: Ultrafiltration nanofiltration combined recovery treatment of milk whey

[0018] Milk whey is a kind of animal protein waste water, which is a very important by-product in cheese production industry. In general, processing 100kg of milk will result in 10kg of cheese and 90kg of whey. In this embodiment, whey produced from fresh milk casein is used as raw material. Firstly, the roll-type polyethersulfone ultrafiltration membrane is used for protein recovery. The ultrafiltration operating conditions are: pressure 0.5MPa, temperature 35°C, pH 4.1, after concentration 9 times, add water amounting to 15% of the raw material volume in two times. After the ultrafiltration, the whey raw material was concentrated about 9 times, the whey protein recovery rate was 87%, the whey protein content increased from the initial 0.62% to 4.87%, and the lactose content decreased from the initial 5.85% to 0.37%. Compounds were reduced from the initial 0.73% to 0.19%, and the ...

Embodiment 2

[0021] Embodiment 2: the nanofiltration recovery treatment of milk whey

[0022] The milk whey is treated with a nanofiltration system, the whey is concentrated more than 3 times, and the permeate is tested, and no protein is detected in it, and the lactose content is 0.01%. The turbidity is significantly lower than that of whey, and it is colorless and transparent , CODcr, BOD5 removal rates were 97.62%, 99.17%.

Embodiment 3

[0023] Embodiment 3: the recycling processing of soybean whey

[0024] Soy whey is produced during the production process of soybean protein isolate. Industrial production of 1 ton of soybean protein isolate requires about 60 tons of whey. The soybean whey is subjected to alkaline precipitation with Ca(OH)2 to obtain a supernatant, and then the supernatant is processed through membrane filtration. Ultrafiltration is used as the first stage of membrane filtration to recover protein; nanofiltration is used as the second stage of membrane filtration to recover oligosaccharides; reverse osmosis is used as the third stage of membrane filtration to intercept amino acids and inorganic salts, and the effluent can be used as process water for recycling use. In the ultrafiltration process, after treatment, the COD value of the whey stock solution drops from 14360 mg.l-1 to below 10 mg.l-1, reaching or approaching pure water and reused in the process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com