Heat treatment method of ultrahard aluminum alloy after chemical nickel-plating

A heat treatment method and electroless nickel plating technology, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problem of the decrease of hardness and strength of super-duralumin substrate, the decrease of hardness of super-duralumin substrate, and the inability to increase significantly Coating hardness and other issues to achieve the effect of expanding the application field and solving the problem of low wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

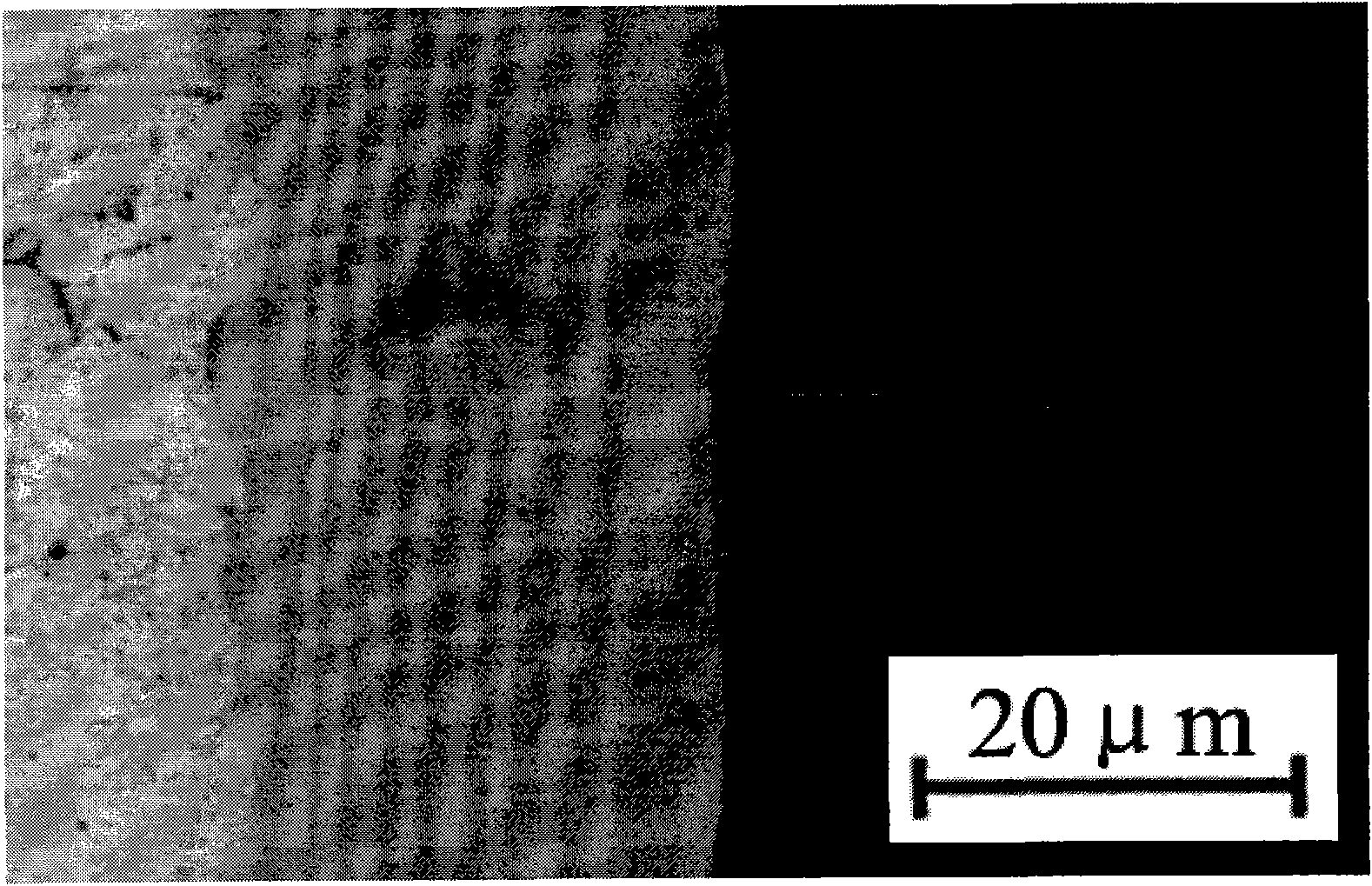

Image

Examples

Embodiment 1

[0022] 1mm thick LC4 superhard aluminum alloy, hardness 120Hv. 5% sodium hydroxide solution 55 ℃, 3min alkali washing, immersion in 50% nitric acid solution for 30s after water washing, immersion in zinc at room temperature for 60s after water washing (the composition of zinc immersion solution is: 240g / L sodium hydroxide+120g / L zinc sulfate+60g / L nickel sulfate+120g / L potassium sodium tartrate+5g / L ferric chloride), 50% nitric acid immersion 5s, after washing with water, dip zinc at room temperature for 30s, after washing, immerse in alkaline electroless nickel plating solution (plating solution consists of: 25g / L L nickel sulfate + 25g / L sodium hypophosphite + 45g / L sodium citrate + 30g / L ammonium chloride, adjust the pH value to 9 with ammonia water, plate at 45°C for 10min, take it out and wash it, then immerse it in the acidic nickel plating solution ( The composition of the plating solution is: 25g / L nickel sulfate + 25g / L sodium hypophosphite + 20g / L lactic acid + 20g / ...

Embodiment 2

[0025] 1mm thick LC4 superhard aluminum alloy electroless nickel plating, the method is as embodiment 1.

[0026] Put the sample in an electric furnace at 475°C for 20 minutes, quench water, and hold at 120°C for 24 hours. The hardness of the substrate is 141Hv, and the hardness of the coating is 880Hv;

Embodiment 3

[0028] 1mm thick LC9 superhard aluminum alloy, hardness 152Hv, electroless nickel plating method as in Example 1. The resulting coating had a hardness of 450 Hv.

[0029] Put the sample in an electric furnace at 465°C for 30 minutes, quench water, and hold at 120°C for 24 hours. The hardness of the substrate is 160Hv, and the hardness of the coating is 860Hv;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Matrix hardness | aaaaa | aaaaa |

| Matrix hardness | aaaaa | aaaaa |

| Matrix hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com