Tower-smelt organic-inorganic compound fertilizer and preparation method thereof

A compound fertilizer and inorganic technology, applied in the agricultural field, can solve the problems of poor solubility and high moisture content of fertilizers, and achieve the effect of low moisture content, high nutrient content, and soil improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

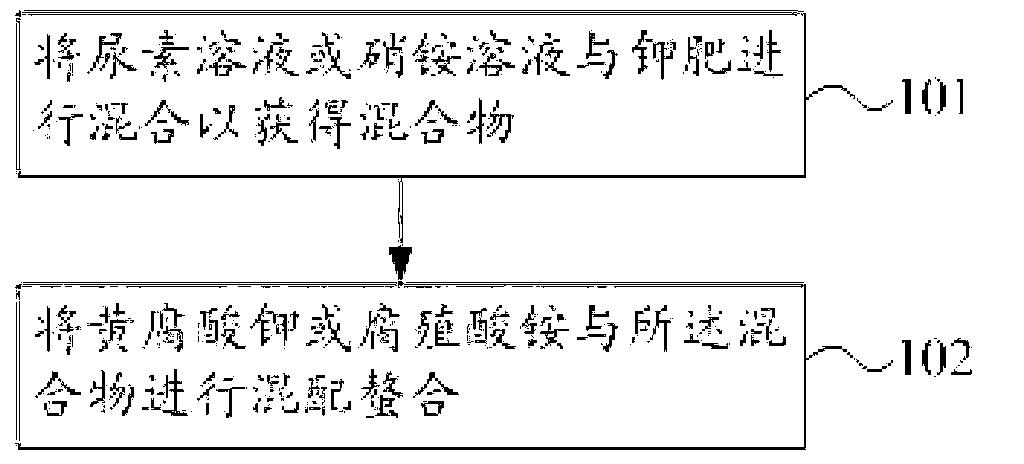

[0025] refer to figure 1 , is the flowchart of the preparation method of the organic-inorganic compound fertilizer of the present invention. The method includes:

[0026] Step 101, mixing urea solution or ammonium nitrate solution with potassium fertilizer to obtain a mixture;

[0027] Wherein, the potassium fertilizer is potassium chloride, and a filler is also included for mixing, and the filler can be one or more of ammonium sulfate, ammonium chloride, and dolomite powder.

[0028] Step 102, mixing and chelating potassium fulvic acid or ammonium humate, monoammonium phosphate and the mixture.

[0029] Mix potassium fertilizer and filler directly with urea solution heated to 130°C-170°C or ammonium nitrate solution heated to 130°C-170°C at 130°C-170°C. Then mix and chelate with monoammonium phosphate, potassium fulvic acid or ammonium humate.

[0030] The method of the invention uses potassium fulvic acid or ammonium humate as organic matter, which has high nutrient cont...

Embodiment 1

[0038] Compound fertilizer product specifications: according to mass percentage, N:P 2 O5:K 2 O=30:5:5, total nutrient ≥ 40%, organic matter ≥ 10%, moisture ≤ 2.0%. Nutrients refer to nitrogen, phosphorus, and potassium, and organic matter refers to potassium fulvate or ammonium humate.

[0039] Lift the urea, monoammonium phosphate, potassium chloride, potassium fulvic acid and filling agent into the silo at the top of the high tower with elevators respectively, and send the urea into the melting tank after metering, heat it to 130°C-170°C and pass through the overflow The flow is mixed and chelated with the metered monoammonium phosphate, potassium chloride, potassium fulvic acid and filler in the mixing tank, and then enters the granulator for spray granulation after being uniform, and after cooling and screening, the qualified The particles are surface treated, and then packaged for delivery.

[0040] Raw material and auxiliary material consumption table:

[0041] ...

Embodiment 2

[0043] Compound fertilizer product specifications: according to mass percentage, N:P 2 O5:K 2 O=20:4:16, total nutrient ≥ 40%, organic matter ≥ 16%, moisture ≤ 2.0%.

[0044] Lift the urea, monoammonium phosphate, potassium chloride, potassium fulvic acid and filling agent into the silo at the top of the high tower with elevators respectively, and send the urea into the melting tank after metering, heat it to 130°C-170°C and pass through the overflow The flow is mixed and chelated with the metered monoammonium phosphate, potassium chloride, potassium fulvic acid and filler in the mixing tank, and then enters the granulator for spray granulation after being uniform, and after cooling and screening, the qualified The particles are surface treated, and then packaged for delivery.

[0045] Raw material and auxiliary material consumption table:

[0046] Raw materials and auxiliary materials

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com