O-phthalaldehyde disinfectant and preparation method thereof

A technology of o-phthalaldehyde and disinfectant, which is applied in the direction of disinfectant, botany equipment and method, biocide, etc., can solve the problems of mild corrosion, easy to be oxidized and damaged, and unsatisfactory killing effect of bacteria and spores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

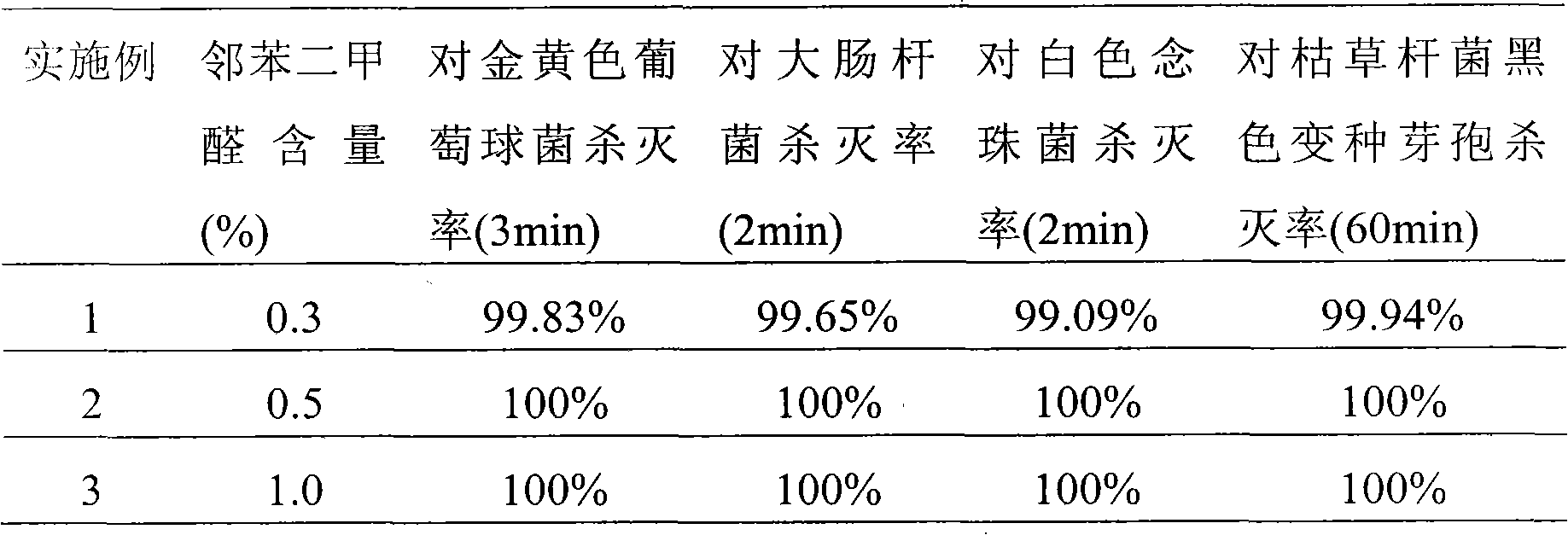

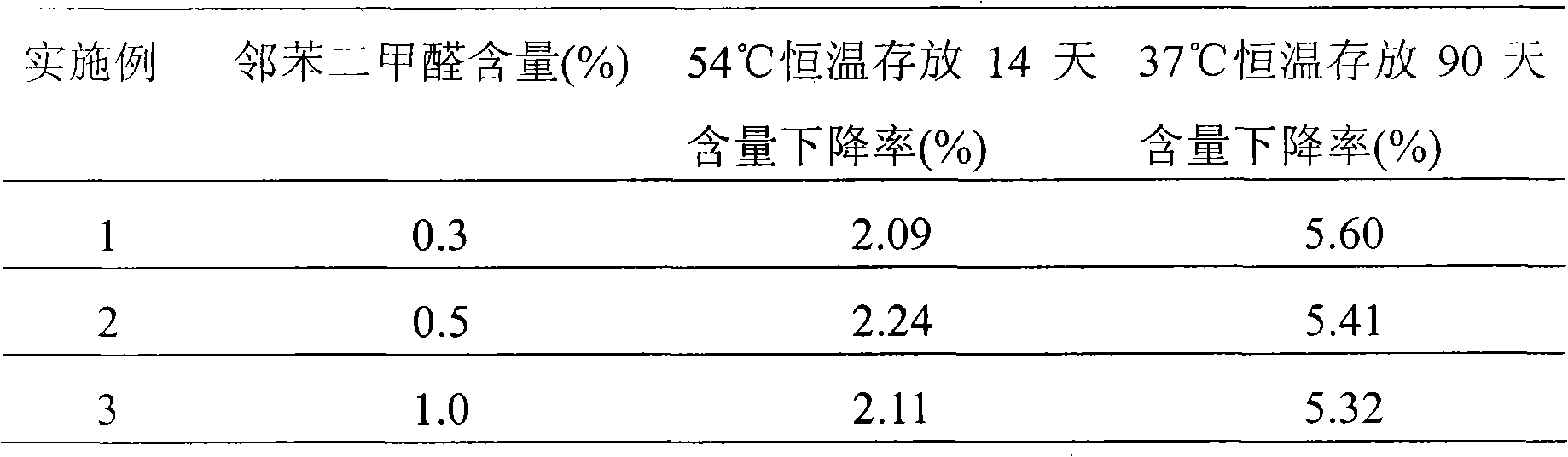

Embodiment 1

[0032] Add 3 grams of o-phthalaldehyde to 5 grams of ethanol, stir and mix; add 967.5 grams of water, stir to dissolve; add 10 grams of dodecyl dimethyl ammonium chloride, 5 grams of disodium hydrogen phosphate, dihydrogen phosphate 4 grams of sodium, 5 grams of sodium metaphosphate, and 0.5 grams of disodium edetate are stirred and dissolved to obtain the described o-phthalaldehyde disinfectant.

Embodiment 2

[0034] Add 5 grams of o-phthalaldehyde to 5 grams of ethanol, stir and mix; add 975.8 grams of water, stir to dissolve; add 5 grams of dodecyldimethylammonium chloride, 2 grams of disodium hydrogen phosphate, dihydrogen phosphate 2 grams of sodium, 5 grams of potassium metaphosphate, and 0.2 grams of disodium edetate are stirred and dissolved to obtain the described o-phthalaldehyde disinfectant.

Embodiment 3

[0036] Add 10 grams of o-phthalaldehyde to 10 grams of ethanol, stir and mix; add 945 grams of water, stir to dissolve; add 15 grams of dodecyl dimethyl ammonium chloride, 8 grams of disodium hydrogen phosphate, dihydrogen phosphate 6 grams of sodium, 2 grams of sodium metaphosphate, 3 grams of potassium metaphosphate, and 1 gram of disodium edetate were stirred and dissolved to obtain the described o-phthalaldehyde disinfectant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com