Catalyst for eliminating carbon soot particles and nitrogen oxides simultaneously, preparation and application thereof

A technology of soot particles and nitrogen oxides, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of low NOx elimination efficiency and achieve reaction The process is easy to control, the production cost is low, and the effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

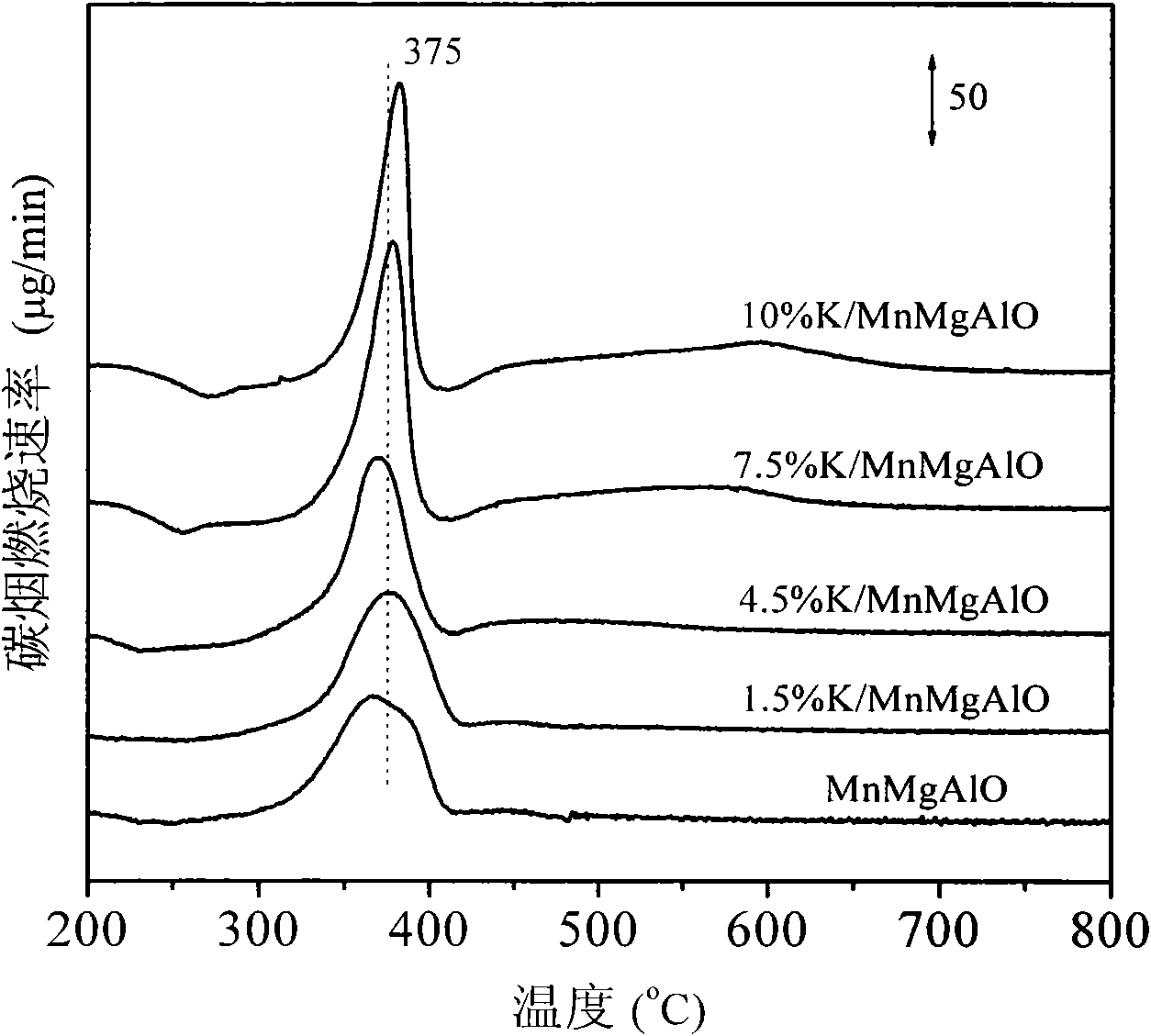

[0015] Example 1 Preparation of MnMgAlO catalyst loaded with 1.5wt.% K

[0016] 1). Weigh 9.191g manganese acetate, 9.615g magnesium nitrate and 9.378g aluminum nitrate, dissolve with 100ml deionized water to obtain a mixed salt solution; in addition, weigh 8g sodium hydroxide and 1.325g anhydrous sodium carbonate, and use 100ml Dissolve in deionized water to obtain a mixed alkali solution;

[0017] 2). Add 100ml of equal volumes of mixed salt solution and lye to the empty beaker dropwise at the same time, and perform mechanical stirring. During the stirring process, adjust the titration speed of the two to control the pH value of the precipitate to be 9-10; the obtained The precipitated solution was stirred and aged in a water bath at 50°C for 2 hours, then suction filtered, and washed with deionized water until the specific conductivity of the filtrate was lower than 5×10 -3 S / m or less. The obtained filter cake was dried in a water bath at 50°C for 10 hours, and then drie...

Embodiment 2

[0019] Example 2 Preparation of 4.5wt.% K-loaded MnMgAlO catalyst

[0020] 1). Same as the preparation process of mixed lye and mixed salt solution in Example 1;

[0021] 2). Add the mixed salt solution and lye into the empty beaker drop by drop at the same time, and carry out mechanical stirring. During the stirring process, adjust the titration speed of the two to control the pH value of the precipitate to be 9-10; Stir and age in a water bath for 2.5 hours, then filter with suction, wash with deionized water until the specific conductivity of the filtrate is lower than 5×10 -3 S / m or less. The obtained filter cake was dried in a water bath at 55°C for 10.5 hours, and then dried in an oven at 100°C for 10.5 hours to obtain a precursor; the precursor was fired in a muffle furnace at 10°C / min to 800°C for 4 hours to obtain MnMgAlO hydrotalcite base composite oxide material;

[0022] 3). Weigh 0.466g potassium nitrate and dissolve it with 450ml deionized water. Add 4 grams ...

Embodiment 3

[0023] Example 3 Preparation of MnMgAlO catalyst loaded with 7.5%wt.%K

[0024] 1). Same as the preparation process of mixed lye and mixed salt solution in Example 1;

[0025] 2). Add the mixed salt solution and lye into the empty beaker drop by drop at the same time, and carry out mechanical stirring. During the stirring process, adjust the titration speed of the two to control the pH value of the precipitate to be 9-10; Stir and age in a water bath for 3 hours, then filter with suction, wash with deionized water until the specific conductivity of the filtrate is lower than 5×10 -3 S / m or less. The obtained filter cake was dried in a water bath at 60°C for 11 hours, and then dried in an oven at 110°C for 11 hours to obtain a precursor; the precursor was fired in a muffle furnace at 10°C / min to 800°C for 4 hours to obtain MnMgAlO hydrotalcite base composite oxide material;

[0026] 3). Weigh 0.777g potassium nitrate and dissolve it with 450ml deionized water. Add 4 grams o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com