Platinum-group metal coating on surface of refractory metal and preparation method thereof

A technology of platinum group metals and refractory metals, applied in metal material coating technology, metal layered products, coatings, etc., can solve the problems of difficult control of process parameters, slow deposition rate, high cost, etc., and achieve easy control of thickness, The effect of fast deposition speed and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

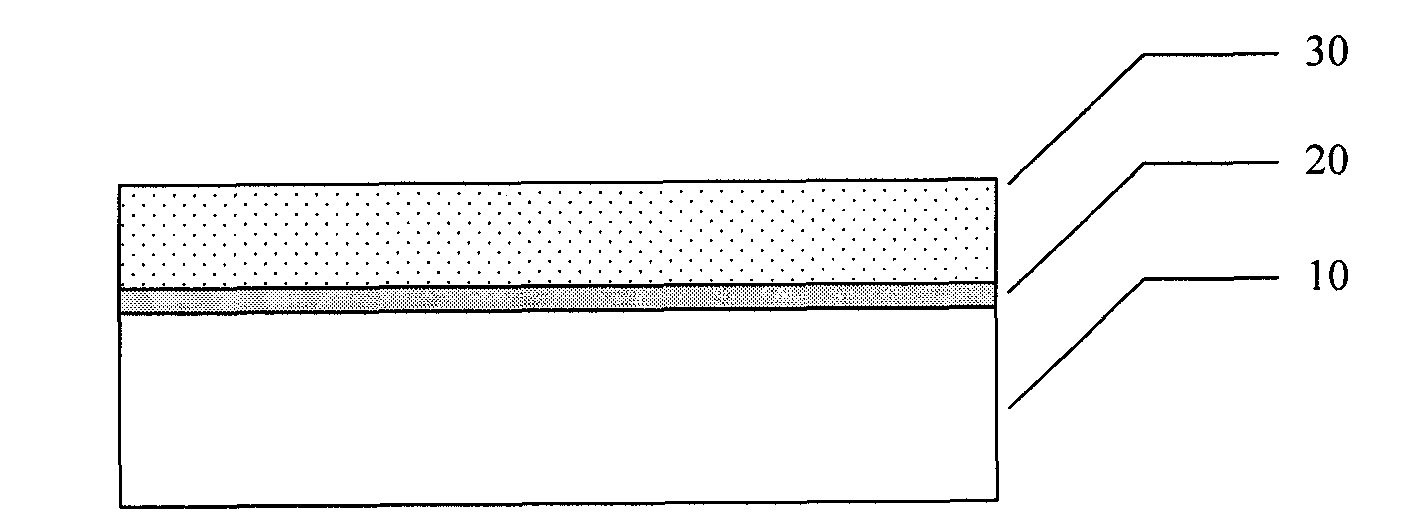

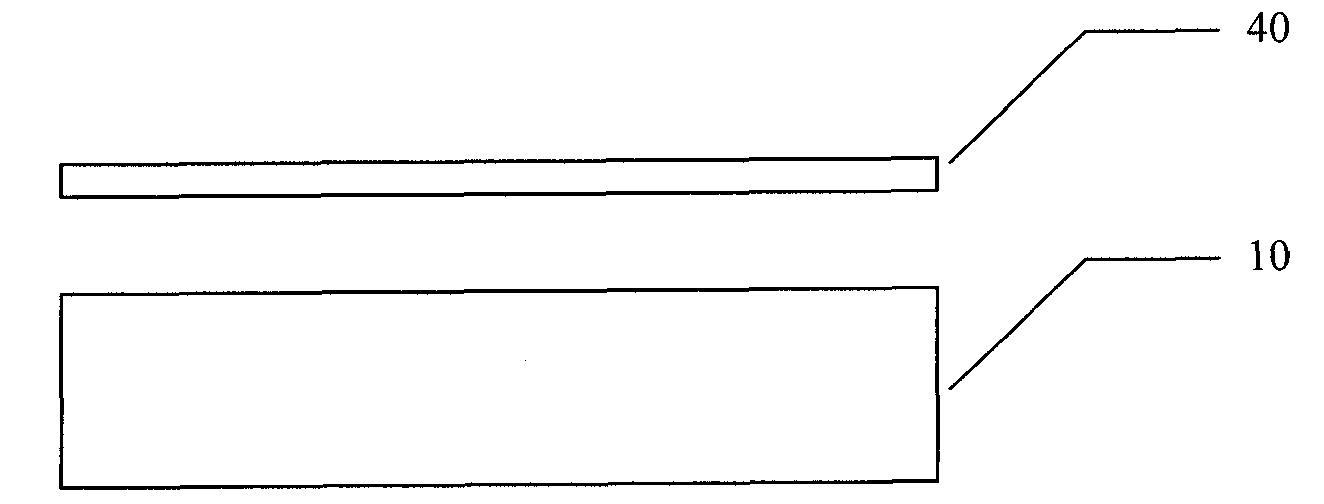

Embodiment 1

[0044] The refractory metal molybdenum plate is used as the substrate, and the size is 15mm×15mm×2mm; the platinum group metal iridium plate is used as the target material, and the size is The surface of the refractory metal sample was treated with metallographic sandpaper, polished, ultrasonically cleaned with acetone or alcohol, and then dried. Install it in the vacuum chamber, adjust the distance between the poles, evacuate to the ultimate vacuum, and then pass in argon. The process parameters for preparing the platinum group metal iridium coating on the refractory metal molybdenum substrate are set as follows: the target voltage is -850V; the substrate voltage is -300~-350V, the working pressure is 35Pa, the iridium target and The distance between molybdenum substrates is 15mm, and the deposition time is 2h. Adjust the molybdenum substrate voltage to -450V first, then turn on the target power after 15 minutes, and deposit the coating according to the above-mentioned set ...

Embodiment 2

[0046] A refractory metal tungsten sample is used as a base material, and a 70% iridium+30% platinum alloy powder metallurgy disk is used as a target material. The surface of the refractory metal tungsten substrate is treated with metallographic sandpaper, polished, ultrasonically cleaned with acetone or alcohol, and then dried. Install it in the vacuum chamber, adjust the distance between the poles, evacuate to the ultimate vacuum, and then pass in argon. The deposition process parameters of the substrate: the working pressure is 45Pa, the target potential is -900V, the substrate potential is -450V, and the electrode spacing is 13mm. First adjust the voltage of the substrate to -550V, and then adjust the voltage of the substrate and the target to -450V and -900V after 20 minutes. After 2h of deposition, a dense platinum-iridium alloy coating with a thickness of 15 μm can be obtained, and the thickness of the transition layer is about 0.9 μm. The prepared platinum-iridium co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com