Pesticide emulsion in water and preparation method thereof

A technology for water emulsion and pesticide, applied in the field of pesticide water emulsion and its preparation, can solve the problems of high production conditions and process requirements, large-scale production restrictions, thermodynamic instability, etc., and achieves high production efficiency, low cost, and easy industrial scale. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 25 kg of lambda-cyhalothrin, 40 kg of D-limonene, 20 kg of castor oil polyoxyethylene ether, and 15 kg of fatty alcohol polyoxyethylene ether phosphate, mix well to obtain an oil phase; weigh 30 kg of n-octanol 1 kg, 20 kg of magnesium aluminum silicate, 1 kg of methyl polysiloxane, and 849 kg of water, mix well to obtain the water phase; under the stirring condition of 2000 rpm, add the water phase to the oil phase. Under the conditions of a resonance frequency of 20 kHz and a power of 200 W, ultrasonic emulsification was performed for 15 minutes to form 1000 kg of efficient cyhalothrin water emulsion.

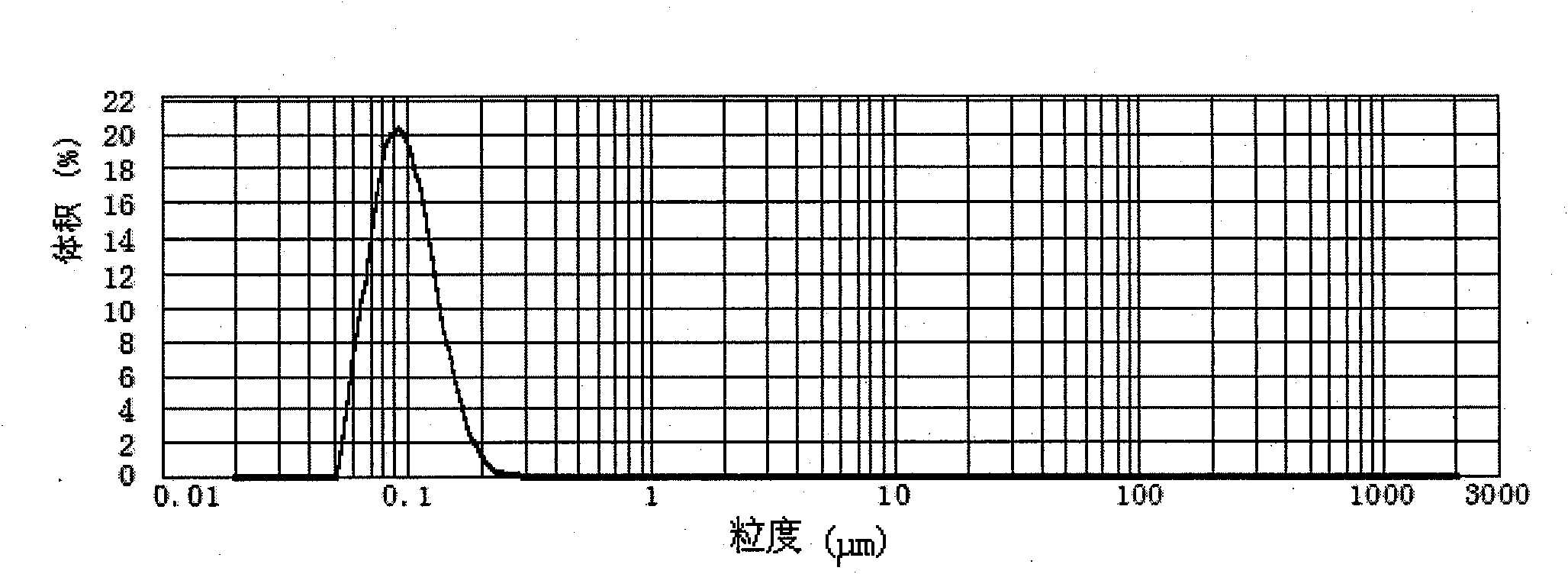

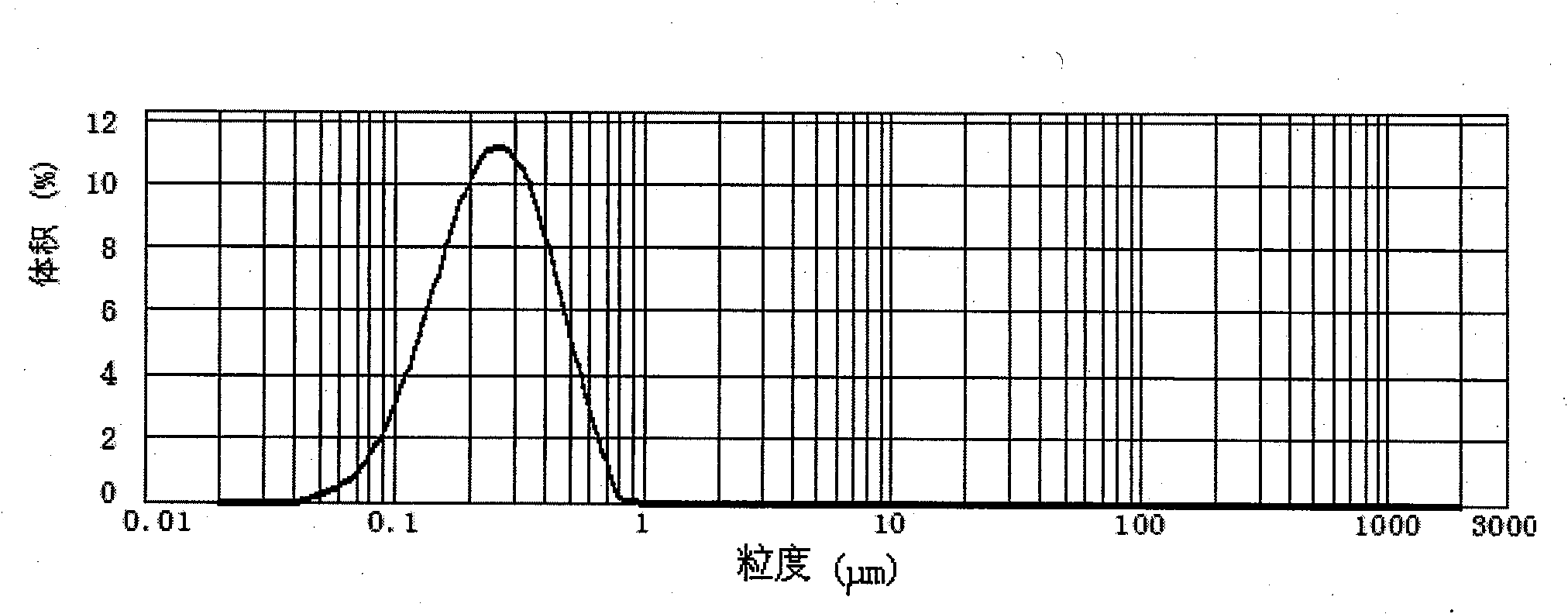

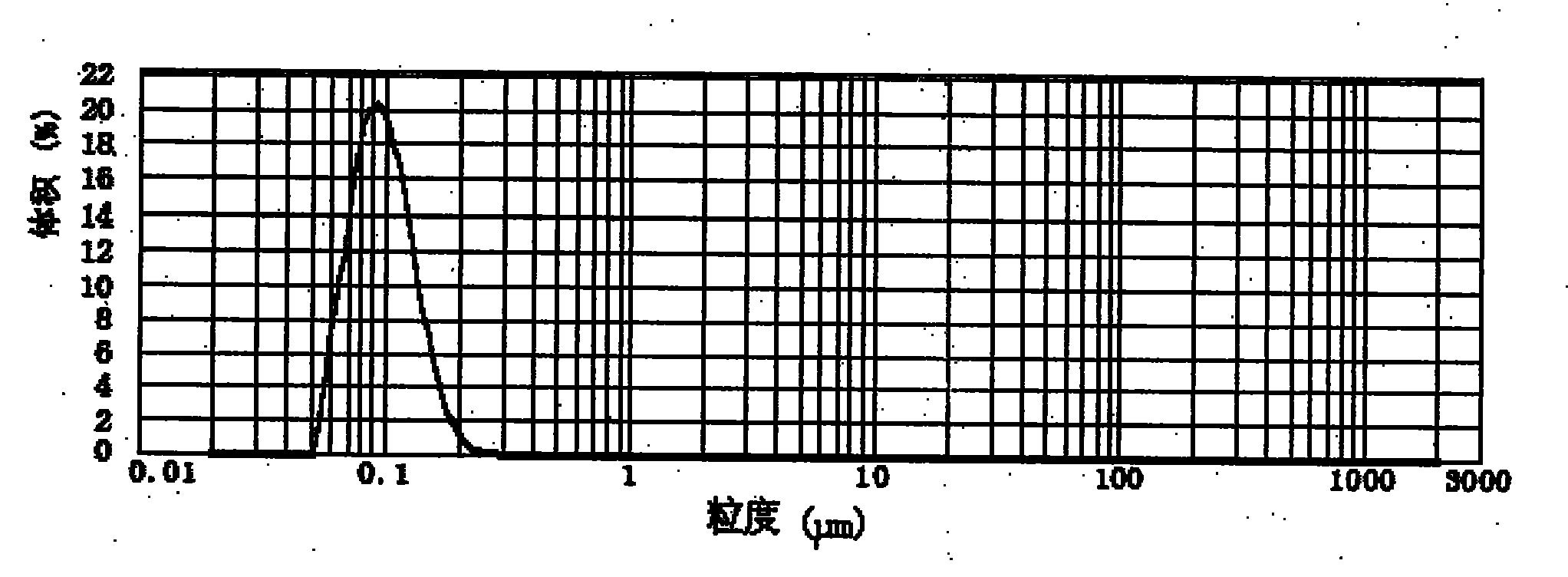

[0027] see figure 1 , figure 2 And table 1, table 2, the droplet of the efficient cyhalothrin water emulsion (being Kungfu water emulsion) prepared by ultrasonic emulsification technology and the 2.5% Kungfu water emulsion (EW090611) prepared by general preparation method compare particle size distribution range Narrow, 95% of the droplet size distribution is ...

Embodiment 2

[0040] Weigh 25 kg of bifenthrin, 35 kg of xylene, 15 kg of polyoxyethylene polyoxypropylene block copolymer, 15 kg of fatty alcohol polyoxyethylene ether phosphate, and mix uniformly to obtain an oil phase; weigh 50 kg of isooctanol 1 kg, 20 kg of polyvinyl alcohol, 1 kg of methyl polysiloxane, and 839 kg of water, and mix evenly to obtain the water phase; under the stirring condition of 2000 rpm, add the water phase to the oil phase. Under the conditions of resonance frequency 20kHz and power 800W, ultrasonic emulsification was performed for 8 minutes to form 1000 kg bifenthrin aqueous emulsion, and 95% of the droplet size distribution was 0.07-0.3 μm.

[0041]Use the bifenthrin water emulsion of the present embodiment to prevent and treat tea tree tea green leafhopper, add water to dilute the field spray according to 3 grams / mu of active ingredients, and the control effects of 2 days and 5 days after the medicine are respectively 86.0% and 92.2%, and the application The bif...

Embodiment 3

[0043] Weigh 100 kg of bifenthrin, 100 kg of Solvesso 200, 25 kg of C12-14 alcohol polyoxyethylene ether, and 20 kg of C12-14 polyoxyethylene ether phosphate, mix well to obtain an oil phase; weigh 40 kg of n-butanol 1 kg, 4 kg of xanthan gum, 1 kg of modified methylpolysiloxane, and 710 kg of water, and mix evenly to obtain a water phase; under the stirring condition of 2000 rpm, add the water phase to the oil phase. Under the conditions of resonant frequency 30kHz and power 200W, ultrasonic emulsification was performed for 12 minutes to form 1000 kg bifenthrin aqueous emulsion, and 95% of the droplet size distribution was 0.06-0.35 μm.

[0044] Use the bifenthrin aqueous emulsion of the present embodiment to prevent and treat tea tree tea green leafhopper, add water to dilute the field spray according to 3 grams / mu of active ingredient, the control effect of 2 days and 5 days after the medicine is respectively 83.9% and 90.6%, and application The bifenthrin aqueous emulsion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mean droplet size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com