Asymmetrically-structural ceramic ultrafiltration membrane and preparation method thereof

A technology of ceramic ultrafiltration membrane and asymmetric structure, which is applied in the field of ceramic ultrafiltration membrane with asymmetric structure and its preparation, which can solve the problems of flux loss, reduction of pore size, long cycle, etc., achieve high selectivity and reduce infiltration , the effect of complete structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

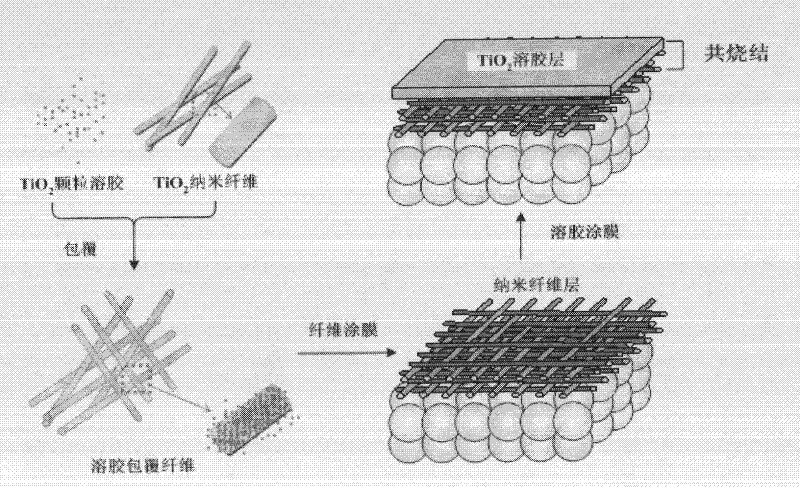

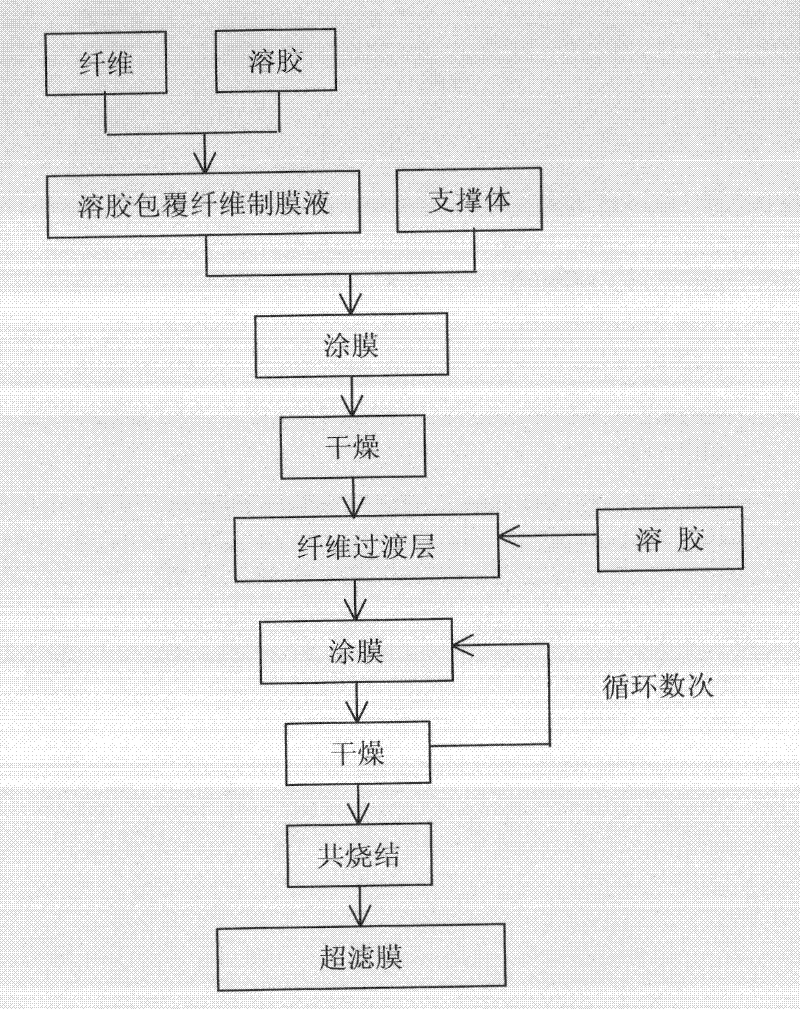

[0027] The preparation of embodiment 1 double-layer titanium oxide ultrafiltration membrane

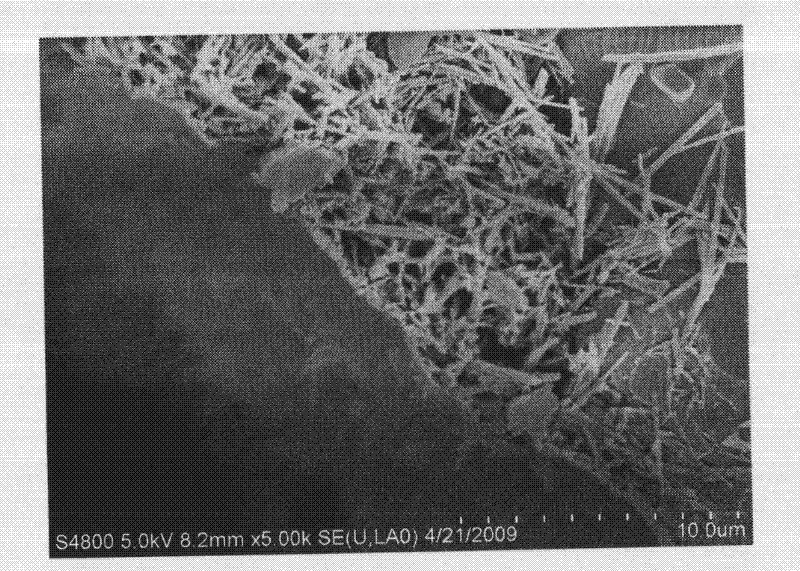

[0028] 5 g of titanium oxide fibers (200 nm in diameter, 50:1 aspect ratio) were added into 80 g of titanium oxide sol and mixed thoroughly. The solid content of the sol was 0.8% (wt%) and the particle size was 25 nm. Nitric acid was added dropwise to adjust the pH of the solution to 3, followed by adding 0.4 g of polyethyleneimine (PEI), 0.4 g of hydroxypropyl cellulose (HPC), 0.1 g of silicone defoamer, and 30 g of deionized water to prepare a mixed solution. After high-speed stirring and ultrasonic dispersion, the coating liquid is prepared, and the film is coated on a flat α-alumina porous carrier with an average pore size of 3 μm, and the temperature is raised to 80 °C at 2 °C / min and dried in a hot air drying oven for 10 hours to form a transition layer. The titanium oxide sol film-making liquid of solid content 0.75% (wt%) is repeatedly coated on the surface of the transition ...

Embodiment 2

[0029] Embodiment 2 Preparation of double-layer titanium oxide / potassium titanate ultrafiltration membrane

[0030] Add 5g of potassium titanate whiskers (diameter: 400nm, aspect ratio: 40:1) into 50g titanium oxide sol and mix well. The sol has a solid content of 0.8% (wt%) and a particle size of 25nm. Nitric acid was added dropwise to adjust the pH of the solution to 4, followed by adding 0.3 g of polyvinylamine (PEI), 0.4 g of polyvinyl alcohol (PVA), 0.1 g of silicone defoamer, and 30 g of deionized water to form a mixed solution, which was passed through high-speed Stir and ultrasonically disperse to prepare a coating solution, coat the tubular titanium oxide porous carrier with an average pore size of 3 μm, raise the temperature at 2 °C / min to 80 °C, and dry in a hot air drying oven for 10 hours to form a transition layer. The titanium oxide sol film-making solution of 0.8% (wt%) of solid content is repeatedly coated on the surface of the transition layer 2 times, and afte...

Embodiment 3

[0031] The preparation of embodiment 3 double-layer silicon oxide / alumina ultrafiltration membranes

[0032] 5g of alumina nanowires (diameter: 10nm, aspect ratio: 50:1) were added into 50g of silica sol and mixed thoroughly. The solid content of the sol was 0.8% (wt%) and the particle size was 25nm. Add dropwise nitric acid to adjust the pH of the solution to 3, add polyethylene glycol (PEG) 0.2g, methyl cellulose (MC) 0.2g, organic silicon defoamer 0.1g, deionized water 30g, and prepare a mixed solution. The coating solution was prepared by high-speed stirring and ultrasonic dispersion, and the film was coated on a flat porous titanium support with an average pore size of 2 μm. The temperature was raised to 60 °C at 2 °C / min and dried in a hot air drying oven for 12 hours to form a transition layer. Coat the surface of the transition layer with a silica sol film-making solution with a solid content of 0.75% (wt%), dry it in a constant temperature and humidity box at 75°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com