Process for preparing silane by magnesium silicide method

A technology of magnesium silicide and silane, applied in the field of improved technology for preparing silane, can solve problems such as high labor intensity, poor safety, environmental pollution, etc., and achieve the effects of increasing production capacity, stabilizing silane gas volume, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

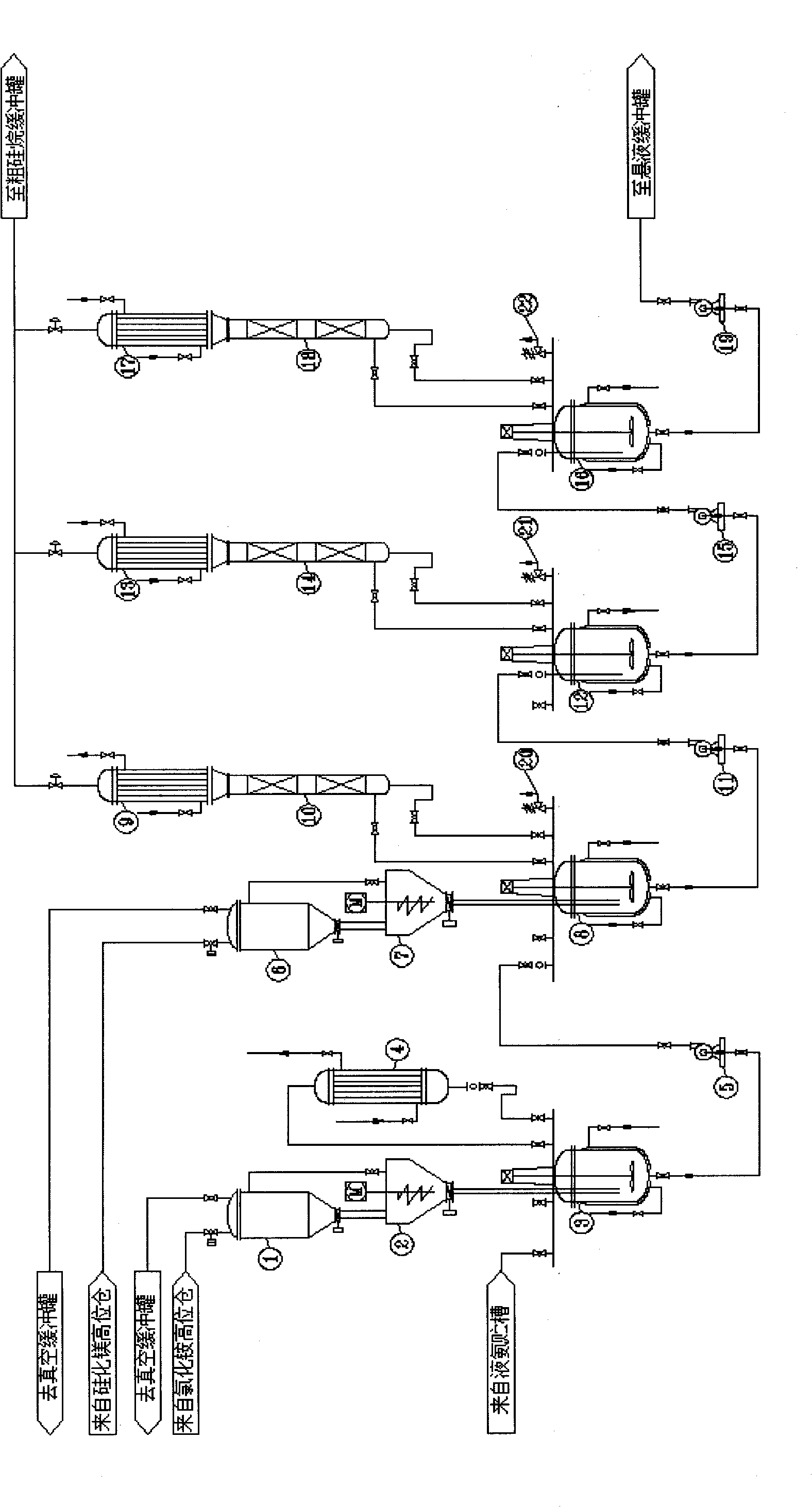

Image

Examples

Embodiment 1

[0031] Example 1 Preparation of 3-stage silane generator in series and continuous silane

[0032] Before silane is generated, replace the entire reaction system with nitrogen gas, and replace the oxygen in the reaction system cleanly;

[0033] After oxygen replacement, liquid ammonia is pumped from the buffer tank into the batching tank 3 at 80 parts per hour, the vaporized ammonia is condensed by the condenser 4 and then returned to the batching tank 3, and ammonium chloride is passed through the high tank 1 at 20 parts per hour. The screw feeder 2 is added to the batching kettle 3 to prepare a 20% ammonium chloride liquid ammonia solution;

[0034] The prepared ammonium chloride liquid ammonia solution is fed into the first-stage silane generator 8 at 100 parts per hour through the pump 5, and at the same time, the magnesium silicide in the magnesium silicide high tank 6 is 6.9 parts per hour (magnesium silicide and ammonium chloride The molar ratio is 1:4.1) The magnesium silicid...

Embodiment 2

[0039] The process flow is the same as in Example 1, except that the amount of liquid ammonia added per hour in Example 1 is changed from 80 parts to 106.7 parts (prepared to 15% ammonium chloride liquid ammonia solution), and other conditions remain unchanged. The yield of the final product silane relative to magnesium silicide was 92.6%.

Embodiment 3

[0041] The process flow is the same as in Example 1, except that the amount of liquid ammonia added per hour in Example 1 is changed from 80 parts to 64 parts (prepared into a 25% ammonium chloride liquid ammonia solution), and other conditions remain unchanged. The yield of the final product silane relative to magnesium silicide was 95.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com