Organic semiconductor material and organic thin film transistor using the same

A technology of thin film transistors and organic semiconductors, applied in the field of organic thin film transistors, can solve problems such as low electron mobility, and achieve the effects of highly ordered thin films, improved self-organization ability, and improved electron mobility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

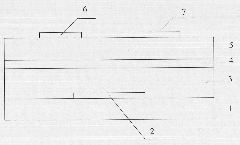

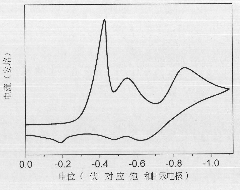

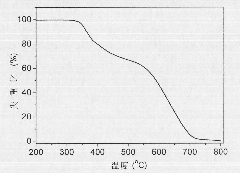

Image

Examples

Embodiment 1

[0058] Into a 500 mL Schlenck reaction flask were added diethyl 2,5-dibromoterephthalate (5.60 g, 14.7 mmol), 5-hexyl-2-tributyltinylthiophene ( 15.5 g, 33.9 mmol), tetrakis (triphenylphosphine) palladium (330 mg, 0.285 mmol) and 250 ml of anhydrous N, N-dimethylformamide (abbreviated as DMF). Stir at 90° C. for 36 hours under dark conditions. Then the reaction mixture was cooled to room temperature, and 1 liter of water was added for liquid separation. The obtained aqueous layer was extracted three times with 50 ml of dichloromethane. The organic phases were combined, extracted twice with saturated brine, 100 ml each time, and dried with anhydrous magnesium sulfate. After the solvent was spin-dried, the reaction mixture was separated through a silica gel column, and the eluent was a mixed solvent of petroleum ether and dichloromethane (volume ratio of 2:1), and finally diethyl 2,5-bis[2'-( 7.42 g of 5'-dihexylthienyl)] terephthalate, and the yield was 91.0%. The reaction f...

Embodiment 2

[0063] Add diethyl 2,5-bis[2′-(5′-dihexylthienyl)]terephthalate (7.1 g , 12.8 mmol), potassium hydroxide (2.87 g, 51.2 mmol), 360 ml of ethanol and 47 ml of water, and the reaction mixture was heated to reflux overnight. After the reaction, the reaction solvent was concentrated to half under reduced pressure, 200 ml of water was added, and then hydrochloric acid with a concentration of 3 moles per liter was added dropwise until no precipitate was formed. The precipitate was filtered and vacuum-dried to obtain 6.21 g of 2,5-bis[2'-(5'-dihexylthienyl)]-1,4-terephthalic acid with a yield of 97.3%. The reaction formula is as follows:

[0064]

[0065] Wherein, R is a hexyl group.

[0066] H NMR spectrum characterization results: 1 H NMR (DMSO-d 6 , 300MHz): δ(ppm) 13.78(b, 2H), 7.05(d, J=3.6Hz, 2H), 6.85(d, J=3.6Hz, 2H), 2.81(t, J=7.5Hz, 4H) , 1.66-1.61 (m, 4H), 1.31-1.29 (m, 8H), 0.87 (t, J=6.6Hz, 6H).

Embodiment 3

[0068] Under an argon atmosphere, 2,5-bis[2′-(5′-dihexylthienyl)]terephthalic acid (4 g, 8.02 mg mol), oxalyl chloride (10.75 g, 84.7 mmol), 200 mL of anhydrous dichloromethane and 1 mL of anhydrous N,N-dimethylformamide. After the reaction mixture was stirred at room temperature for 12 hours, the solvent was distilled off under reduced pressure to obtain 2,5-bis[2'-(5'-dihexylthienyl)]terephthalic acid chloride. The reaction formula is as follows:

[0069]

[0070] Wherein, R is a hexyl group.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com