Externally-sleeved insulated sleeve

An insulating sleeve and sheath type technology, which is applied in the direction of insulated conductors, insulated cables, organic insulators, etc., can solve the problems of large skin effect, easy to generate corona discharge, and low safety factor of copper bus bars, and achieve reliable insulation performance , low cost and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

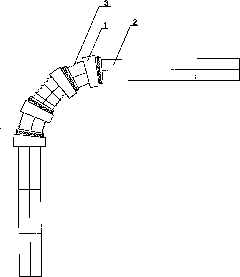

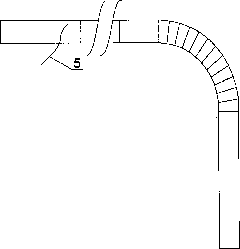

[0015] Such as figure 1 , figure 2 As shown, the jacket-type insulating sleeve is composed of: polyethylene adhesive sleeve 1, conductor 2, epoxy resin coating 3, aluminum foil 4, copper tape 5, semi-conductive material 6, polytetrafluoroethylene film 7, insulation The busbar 8, the outer protective cover 9, and the silicone grease coating 10 are composed of a conductor 2 with a regular shape, the surface burrs are removed, the surface dust is removed by scrubbing with alcohol, and epoxy resin coating is applied on the surface of the conductor 2. 3. The main function is to eliminate the air gap between the electrical conductor 2 and the polyethylene adhesive material 1 to prevent partial discharge, and put the polyethylene adhesive material sleeve 1 on the electrical conductor 2.

[0016] Such as figure 1 , figure 2 As shown, the polyethylene rubber joint material casing 1 is divided into several sections, and is divided into several small sections at the bends. The head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com