Preparation method of piperazine functionalized ordered mesoporous phenolic resin solid base catalyst

A solid base catalyst, phenolic resin technology, applied in the preparation of organic compounds, physical/chemical process catalysts, chemical instruments and methods, etc. The effect of strength, good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

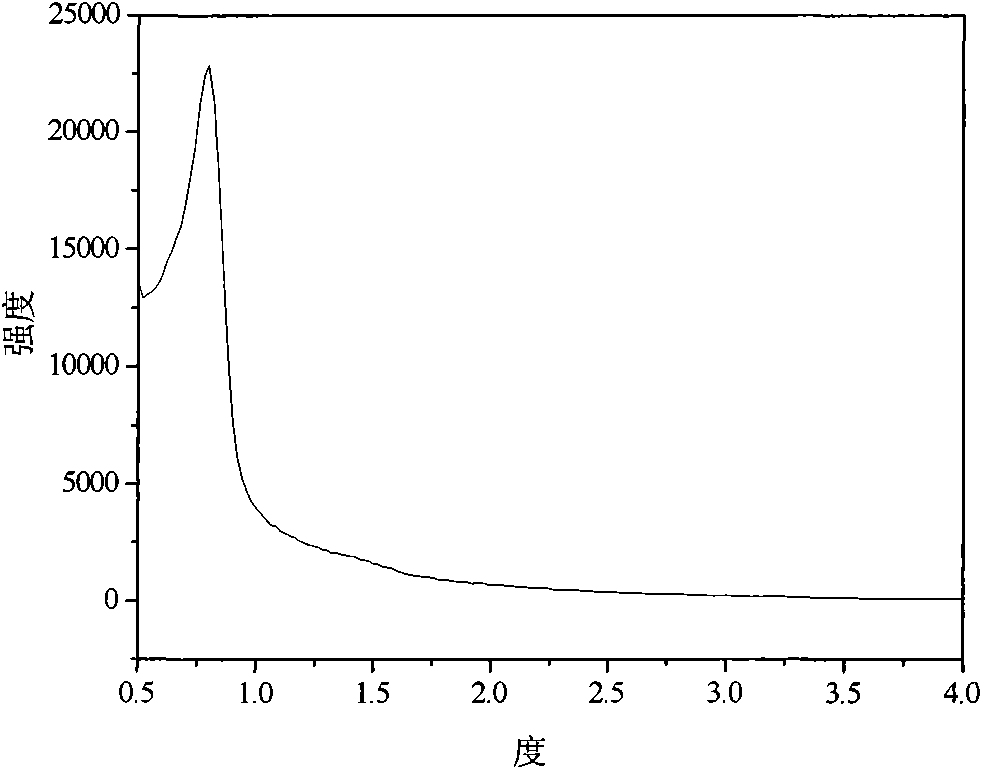

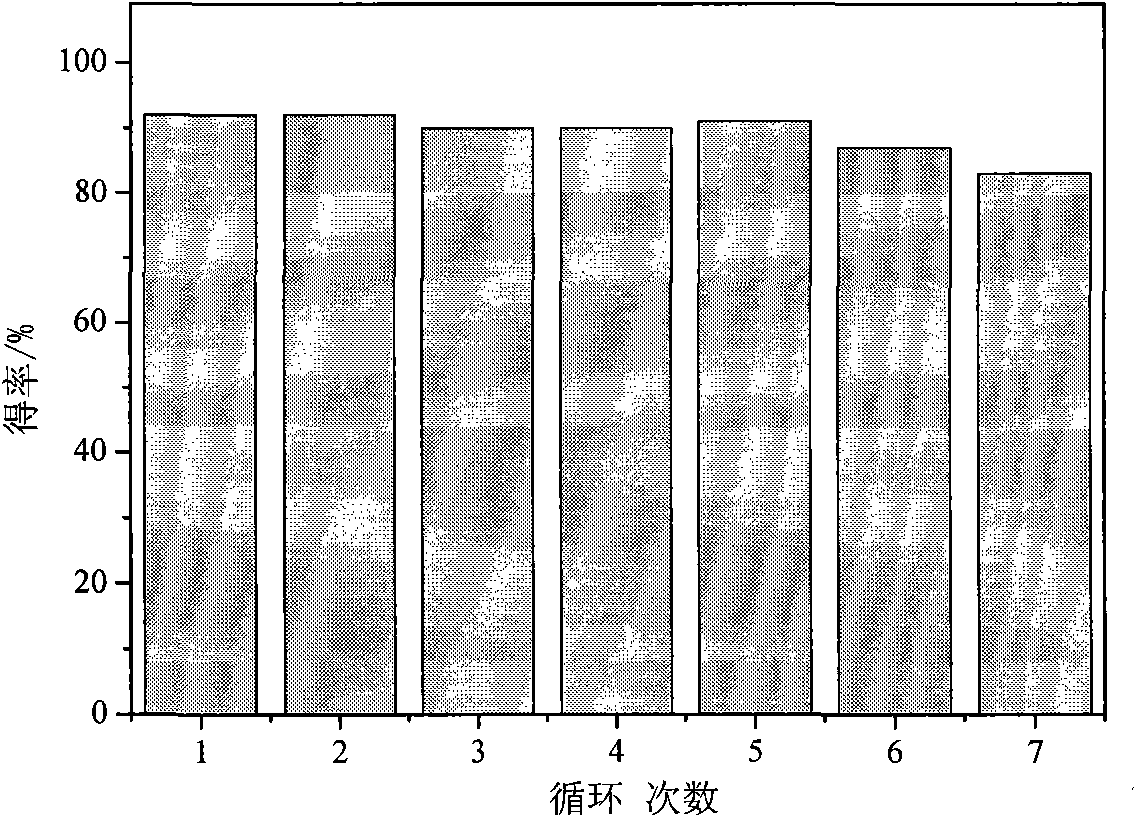

Embodiment 1

[0026] At 308K, 2.4g of phenol (Phenol), 0.52g of 20% sodium hydroxide aqueous solution and 0.027ml of piperazine functionalized formaldehyde Formylpiperazine, 37% of formaldehyde solution were stirred and mixed, and then reacted at a temperature of 340~350K for 10min, A phenolic resin (Piperazidine-MPs) prepolymer with Piperazidine functional groups was obtained, which was subsequently formulated into a 20% ethanol solution by mass. Add 0.90g of triblock copolymer Pluronic F127 (EO106PO70EO106, M w =12600, Aldrich) ethanol solution, after standing at room temperature for 5h, further solidified at 373K temperature, 48w%H 2 SO 4 Extraction, the obtained dark brown solid was washed with saturated aqueous sodium carbonate solution, then washed with a large amount of deionized water and alcohol until the washing liquid was neutral and the presence of carbonate ions could not be detected, then the sample was vacuum-dried, and finally obtained Ordered mesoporous phenolic resin mat...

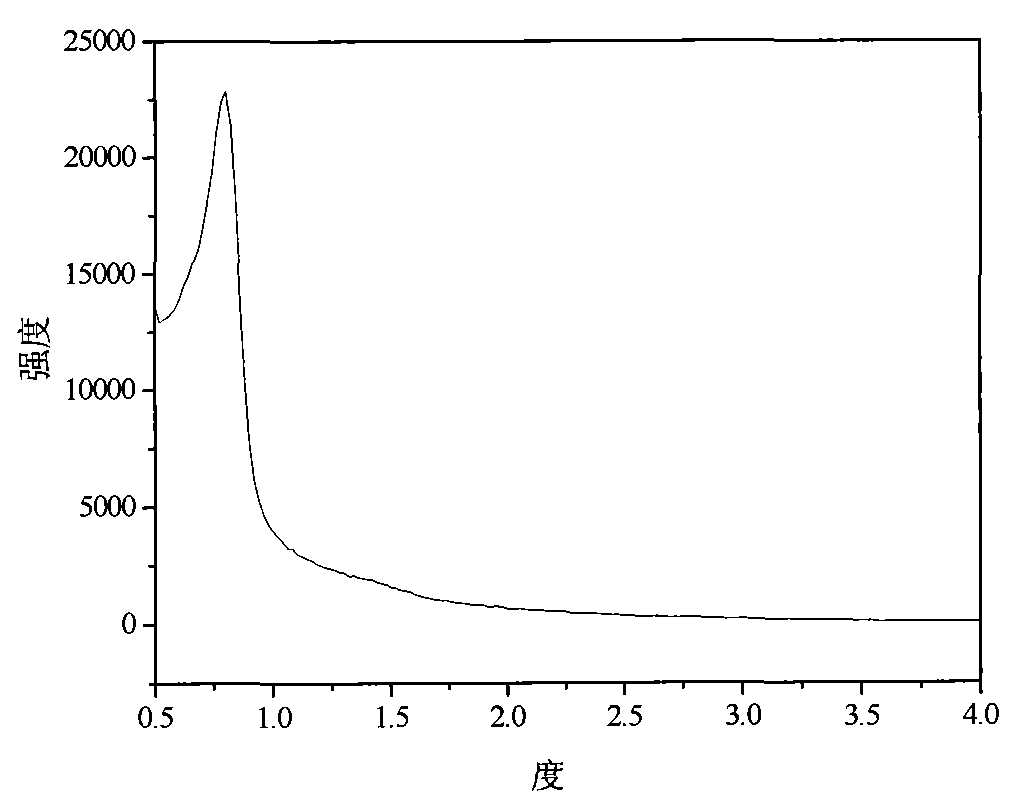

Embodiment 2

[0028] At 318K, 2.4g phenol (Phenol), 0.52g 20% aqueous sodium hydroxide solution and 0.082ml piperazine functionalized formaldehyde Formylpiperazine, 37% formaldehyde solution were stirred and mixed, then reacted at 350K for 1h to obtain There is the phenolic resin (Piperazidine-MPs) prepolymer of Piperazidine functional group, then it is made into ethanol solution with a mass ratio of 20%. Add 1.10 g of triblock copolymer Pluronic F127 (EO106PO70EO106, M w =12600, Aldrich) ethanol solution, after standing at room temperature for 8h, further solidified at 383K temperature, 48w%H 2 SO 4 Extraction, the obtained dark brown solid was washed with saturated aqueous sodium carbonate solution, then washed with a large amount of deionized water and alcohol until the washing liquid was neutral and the presence of carbonate ions could not be detected, then the sample was vacuum-dried, and finally obtained Ordered mesoporous phenolic resin materials with piperazidine functional grou...

Embodiment 3

[0030] At 310K, 2.4g phenol (Phenol), 0.52g 20% sodium hydroxide aqueous solution and 0.050ml piperazine functionalized formaldehyde Formylpiperazine, 37% formaldehyde solution were stirred and mixed, then reacted at 345K temperature for 30min to obtain There is the phenolic resin (Piperazidine-MPs) prepolymer of Piperazidine functional group, then it is made into ethanol solution with a mass ratio of 20%. Add 1.00 g of triblock copolymer PluronicF127 (EO106PO70EO106, M w=12600, Aldrich) ethanol solution, after standing at room temperature for 6h, further solidified at 380K temperature, 48w%H 2 SO 4 Extraction, the obtained dark brown solid was washed with saturated aqueous sodium carbonate solution, then washed with a large amount of deionized water and alcohol until the washing liquid was neutral and the presence of carbonate ions could not be detected, then the sample was vacuum-dried, and finally obtained Ordered mesoporous phenolic resin materials with piperazidine fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com