Method and system for extracting and separating natural VE from plant oil deodorizing distillate

A technology for deodorizing distillate and vegetable oil, which is applied in the field of extraction and separation of natural VE, can solve the problems of aggravated VE decomposition, increased production cost, and is not easy to control, and achieves high concentration ratio and yield, simple operation process, and operation cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

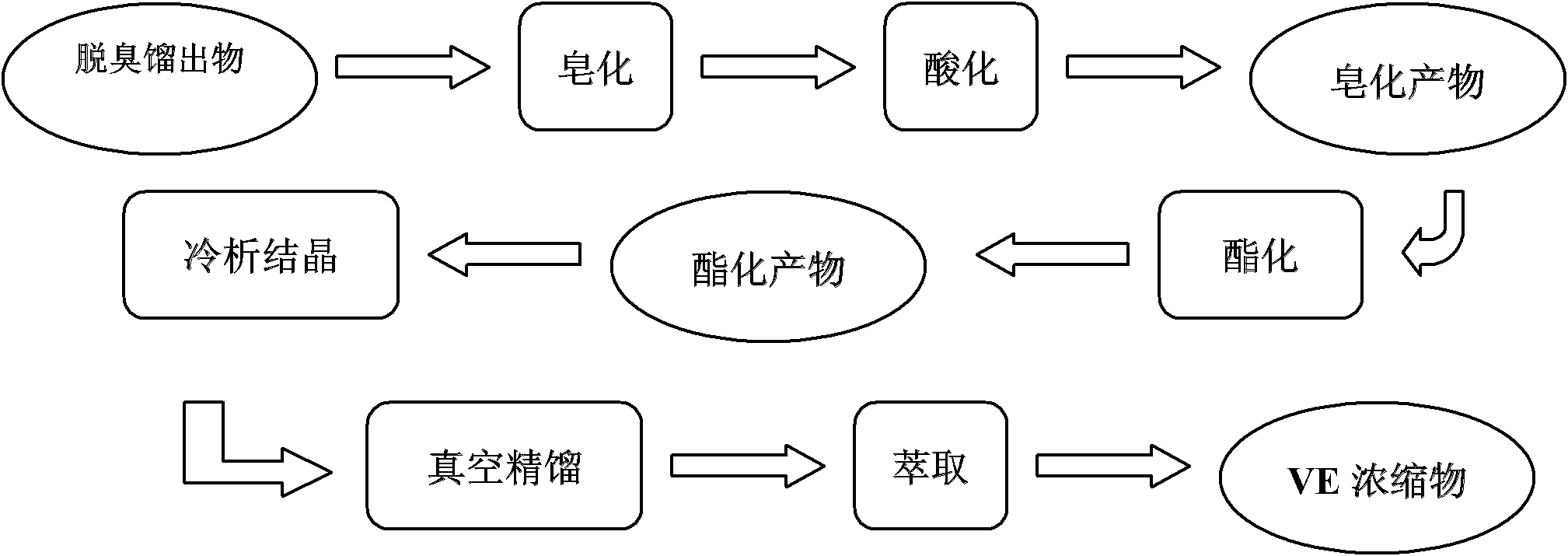

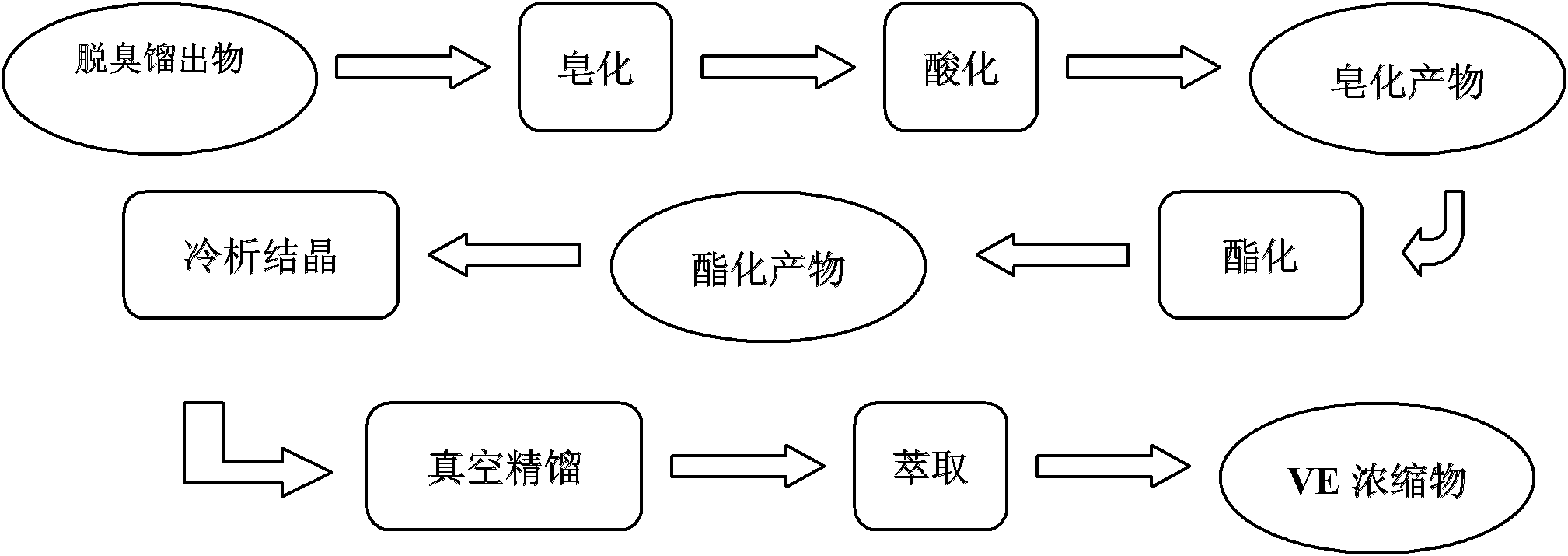

[0034] Apply saponification esterification-rectification method to extract the method for concentrating natural VE, comprise the steps:

[0035]1) Saponification and acidification: Take 20g of soybean oil deodorization distillate (acid value 70.7, saponification value 143.2, mixed VE5.42%), add 60g methanol, 7.001g 45% KOH aqueous solution, stir and reflux at 70°C for 45min. Acidify with 25% hydrochloric acid aqueous solution, wash and dry with water, and remove the solvent by rotary evaporation to obtain 18.72 g of the product with an acid value of 138.9 and a VE preservation rate of 91.6%.

[0036] 2) Esterification: Take 20g of the above-mentioned saponified acidification product, react with 56g of methanol, the catalyst is NKC-9 strong acid type cation exchange resin (6g in dosage), 4A molecular sieve is used as water absorbing agent (4g in dosage), stir and reflux at 70°C for 4h . 19.76 g of the esterification product was obtained, the acid value was 1.47, and the VE pre...

Embodiment 2

[0043] Basic technology is with embodiment 1, and concrete operation parameter is as follows:

[0044] 1) Saponification and acidification: Take 20g of soybean oil deodorization distillate (acid value 70.7, saponification value 143.2, mixed VE5.42%), add 80g methanol, 8.910g 45% KOH aqueous solution, stir and reflux at 70°C for 80min. Acidify with 25% sulfuric acid aqueous solution, wash and dry with water, and remove the solvent by rotary evaporation to obtain 18.89 g of the product, with an acid value of 140.3 and a VE preservation rate of 94.6%.

[0045] 2) Esterification: take 20g of the above-mentioned saponified acidification product, react with 24g of methanol, the catalyst is NKC-9 strong acid type cation exchange resin (the dosage is 2g), 4A molecular sieve is used as the water absorbing agent (the dosage is 6g), stir and reflux at 65°C for 5h . 19.36 g of the esterified product was obtained, the acid value was 2.86, and the VE preservation rate was 95.4%. The ester...

Embodiment 3

[0052] Basic technology is with embodiment 1, and concrete operation parameter is as follows:

[0053] 1) Saponification and acidification: Take 20g of soybean oil deodorization distillate (acid value 71.6, saponification value 142.1, mixed VE8.39%), add 40g methanol, 5.684g 45% KOH aqueous solution, stir and reflux at 65°C for 30min. Acidify with 25% hydrochloric acid aqueous solution, wash and dry with water, and remove the solvent by rotary evaporation to obtain 18.86 g of the product with an acid value of 137.2 and a VE preservation rate of 92.1%.

[0054] 2) Esterification: Take 20g of the above-mentioned saponified acidification product, react with 40g of methanol, the catalyst is NKC-9 strong acid type cation exchange resin (4g in dosage), 4A molecular sieve is used as water absorbing agent (5g in dosage), stir and reflux at 68°C for 4h . 19.48 g of the esterification product was obtained, the acid value was 2.48, and the VE preservation rate was 95.1%. The esterified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com