Method for preparing nano-structured matrix on surface of uneven substrate

A nanostructure and substrate surface technology, applied in the field of nanotechnology, can solve the problems that the exposure system cannot be micro-nano-processed on non-flat surfaces, cannot accurately control the position and force, and the processing of hard film masks is difficult. Effects of acid-base stability and thermal stability, convenient desorption and transfer, and avoidance of diffraction problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

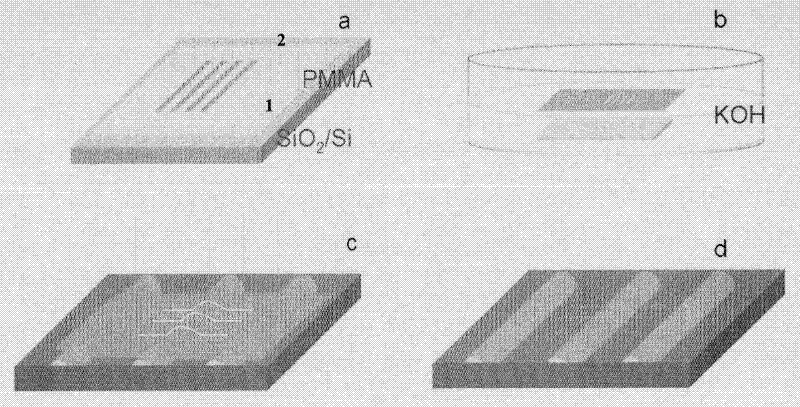

Method used

Image

Examples

Embodiment 1

[0030] 1) Combine Si and SiO 2 Composite substrate composed of (wherein, the lattice orientation of Si sheet is 111, SiO 2 The thickness of the layer is 300 nanometers) and cut into small pieces of 1 cm×1 cm, ultrasonicated through acetone, absolute ethanol, and deionized water for five minutes respectively, and dried with nitrogen gas for later use. Mark the above-mentioned small piece of silicon wafer as substrate A.

[0031] On the substrate A, it is 671.06 PMMA (the weight average molecular weight is 950K) chloroform solution (mass percentage concentration is 6%) with the speed spin-coating model of 4000 revs / second on the substrate A, hot stage 180 ℃ glue-baking 4 minutes, obtain thickness 600 nm photoresist layer.

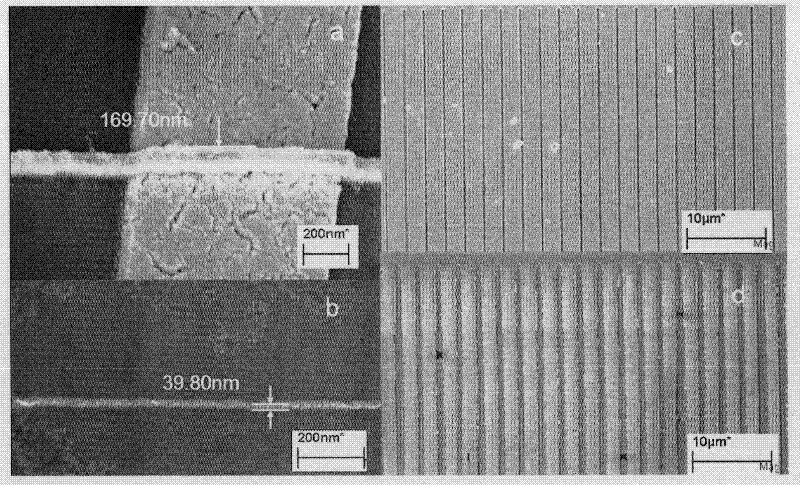

[0032] 2) The sample A that is spin-coated with PMMA is put into the electron beam exposure machine (Raith e Line), under the acceleration voltage of 15KV, with 150uAS / cm 2 Dose exposure to get a pre-designed pattern, develop for 90 seconds, and fix for on...

Embodiment 2

[0039] 1) Combine Si and SiO 2 Composite substrate composed of (wherein, the lattice orientation of Si sheet is 111, SiO 2 The thickness of the layer is 300 nanometers) and cut into small pieces of 1 cm×1 cm, ultrasonicated through acetone, absolute ethanol, and deionized water for five minutes respectively, and dried with nitrogen gas for later use. Mark the above-mentioned small piece of silicon wafer as substrate A.

[0040] After the chloroform solution (mass percentage concentration is 1%) of the PMMA (weight average molecular weight is 495K) of 671.06 PMMA (weight average molecular weight) with the speed spin-coating model of 2000 rev / s on substrate A, hot stage 180 ℃ of glue-baking 2 minutes, obtain A photoresist layer with a thickness of 120 nm.

[0041] 2) Put the sample A which is spin-coated with PMMA into the electron beam exposure machine (Raith e_Line), under the acceleration voltage of 10KV, with 100uAS / cm 2 Dose exposure to get a pre-designed pattern, 60 sec...

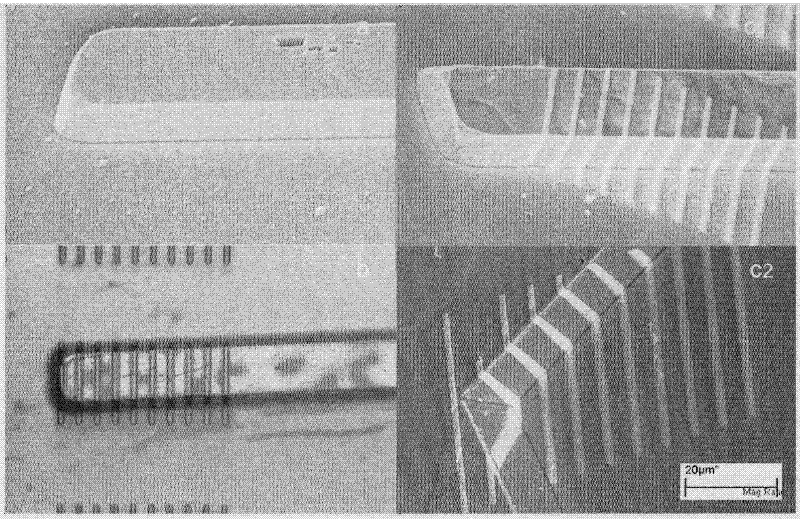

Embodiment 3

[0048] 1) Combine Si and SiO 2 Composite substrate composed of (wherein, the lattice orientation of Si sheet is 111, SiO 2 The thickness of the layer is 300 nanometers) and cut into small pieces of 1 cm×1 cm, ultrasonicated through acetone, absolute ethanol, and deionized water for five minutes respectively, and dried with nitrogen gas for later use. Mark the above-mentioned small piece of silicon wafer as substrate A.

[0049] After the chloroform solution (mass percentage concentration is 6%) of the PMMA (weight average molecular weight is 950K) of 671.06 PMMA (weight average molecular weight is 6%) with the speed spin coating model of 2000 rev / s on substrate A, hot stage 180 ℃ of glue-baking 4 minutes, obtain Photoresist layer with a thickness of 600 nm.

[0050] 2) The sample A that is spin-coated with PMMA is put into the electron beam exposure machine (Raith e_Line), under the accelerating voltage of 15KV, with 150uAS / cm 2 Dose exposure to get a pre-designed pattern, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com