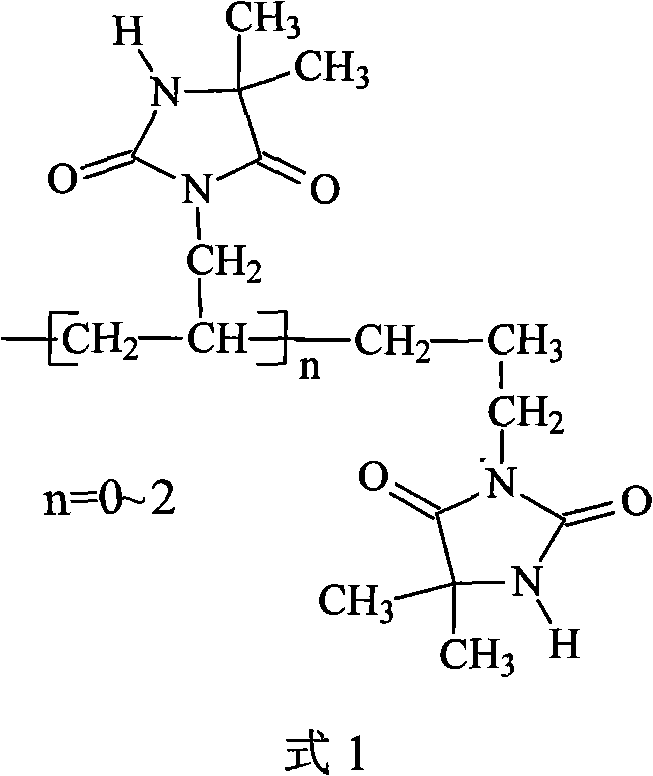

Aromaticpolyamide composite reverse osmosis membrane modified by graft polymerization and preparation method thereof

A technology of aromatic polyamide and reverse osmosis membrane, which is applied in semi-permeable membrane separation, chemical instruments and methods, permeation/dialysis water/sewage treatment, etc. It can solve the problems of inconspicuous grafting and achieve simple process and chlorine resistance Good, easy-to-implement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Dissolve 12.8g of 5,5-dimethylhydantoin in 50mL of an aqueous solution containing 5.6g of potassium hydroxide; dissolve 8.8mL of allyl bromide in 20mL of methanol; Stir in a constant temperature water bath for 2 hours, cool to 25°C, and dry under reduced pressure at this temperature to obtain a solid substance; finally, use 500 mL of petroleum ether to recrystallize the solid substance to obtain monomer ADMH.

[0014] The aromatic polyamide composite reverse osmosis membrane (RE2521-TL aromatic polyamide composite reverse osmosis membrane from Sehan Company) was rinsed with deionized water, and then the membrane surface was purged with nitrogen until dry. The aqueous solution containing the initiator AIBA with a mass concentration of 0.02% and the monomer ADMH with a mass concentration of 5.0% were respectively prepared. First, pour the initiator AIBA solution on the surface of the aromatic polyamide composite reverse osmosis membrane. After 15 minutes, remove the initi...

Embodiment 2

[0019] Firstly, the monomer ADMH was prepared by the same method as in Example 1. The difference from Example 1 was that the initiator AIBA and the monomer were loaded once during the preparation of the grafted polymerization modified aromatic polyamide composite reverse osmosis membrane. The operation of ADMH, and then change the time of graft polymerization to 10min.

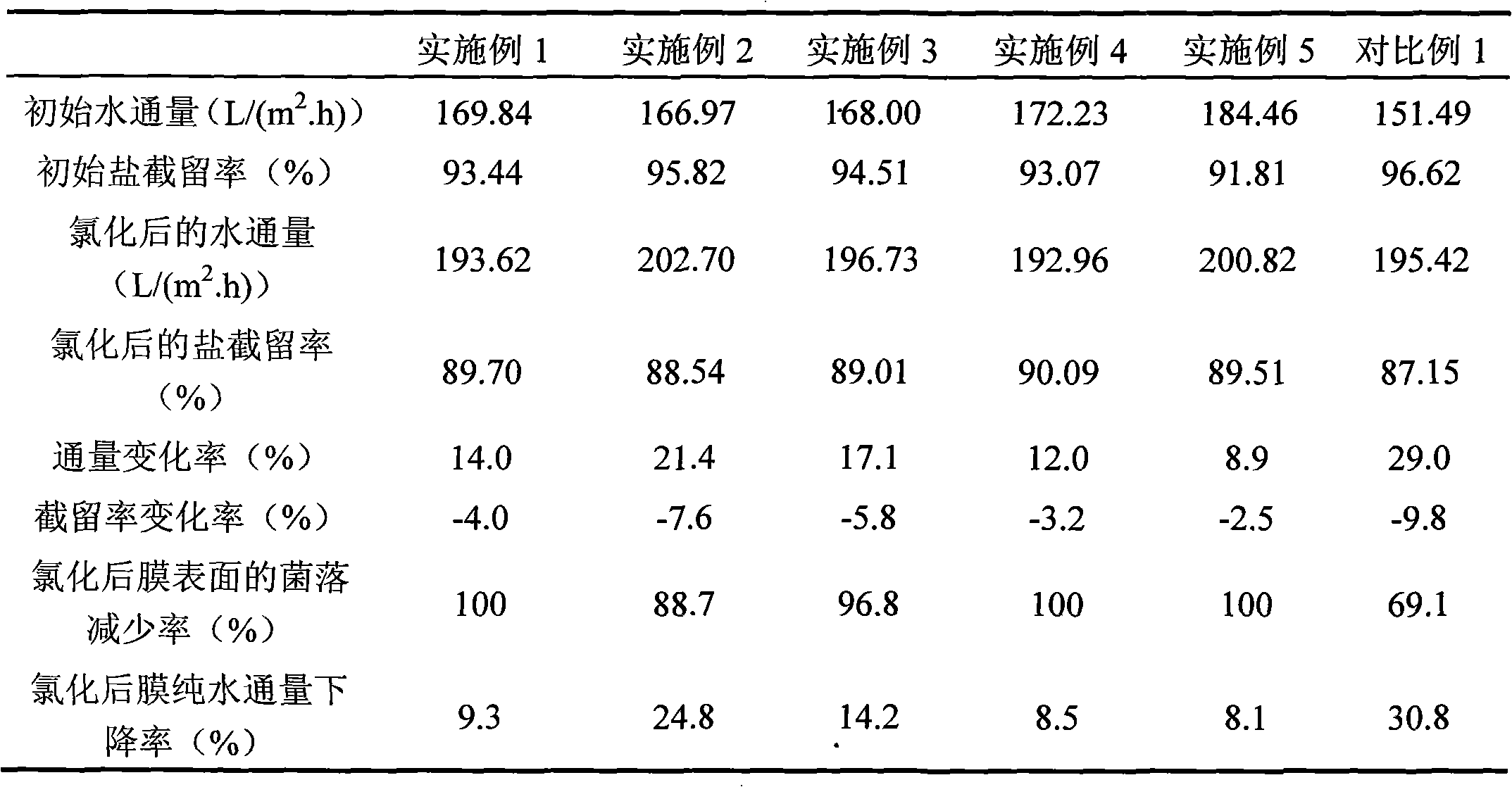

[0020] The obtained graft polymerization modified aromatic polyamide composite reverse osmosis membrane was evaluated for chlorine resistance and anti-microbial pollution performance in the same manner as in Example 1, and the performance parameters are shown in Table 1.

Embodiment 3

[0022]Firstly, the monomer ADMH was prepared by the same method as in Example 1. The difference from Example 1 was that the initiator AIBA and the monomer were loaded once during the preparation of the grafted polymerization modified aromatic polyamide composite reverse osmosis membrane. The operation of ADMH, and then change the time of graft polymerization to 20min.

[0023] The obtained graft polymerization modified aromatic polyamide composite reverse osmosis membrane was evaluated for chlorine resistance and anti-microbial pollution performance in the same manner as in Example 1, and the performance parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Salt rejection | aaaaa | aaaaa |

| Salt rejection | aaaaa | aaaaa |

| Salt rejection | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com