Silicon quantum dot solar cell and preparation method thereof

A technology of solar cells and silicon quantum dots, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of high cost, many materials, light-induced attenuation effect, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

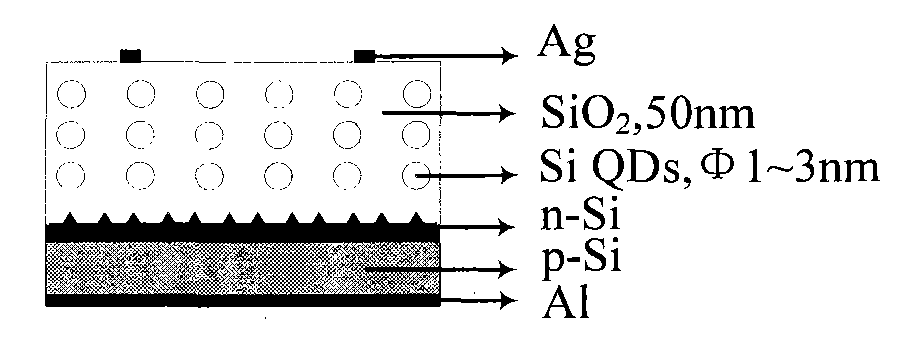

Embodiment 1

[0051] Prepare p-type (100) crystalline silicon with a thickness of 200um, and its boron doping concentration is 10 15 cm -3 , with a resistivity of 5 ohm cm, used as a substrate after cleaning with a standard semiconductor process;

[0052] On the p-type crystalline silicon substrate, sodium silicate Na with a mass fraction of 1.6% 2 SiO 3 , Sodium hydroxide NaOH with a mass fraction of 2.0% and isopropanol IPA solution with a volume fraction of 6% for texturing, that is, a water bath at 78°C to 83°C for 25 minutes to form a surface pyramid structure with a height of 6um to 8um to reduce the solar cell Surface reflectivity, increase the absorption coefficient of sunlight;

[0053] Diffusion of phosphorus oxychloride on the p-type crystalline silicon substrate to form a phosphorus concentration of 10 15 cm -3 The n-type layer;

[0054] Using PVD, that is, magnetron sputtering, a silicon monoxide film with a thickness of 50nm is prepared on the substrate with a silicon mo...

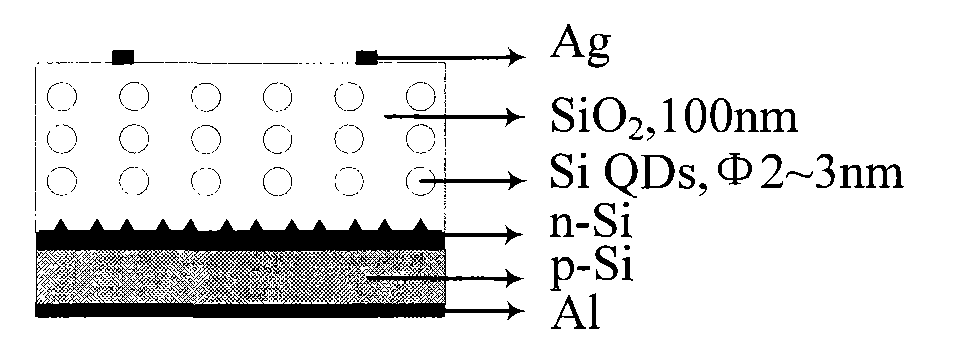

Embodiment 2

[0060] Prepare p-type (100) crystalline silicon with a thickness of 200um, and its boron doping concentration is 10 15 cm -3 , with a resistivity of 5 ohm cm, used as a substrate after cleaning with a standard semiconductor process;

[0061] On the p-type crystalline silicon substrate, sodium silicate Na with a mass fraction of 1.6% 2 SiO 3 , Sodium hydroxide NaOH with a mass fraction of 2.0% and isopropanol IPA solution with a volume fraction of 6% for texturing, that is, a water bath at 78°C to 83°C for 25 minutes to form a surface pyramid structure with a height of 6um to 8um to reduce the solar cell Surface reflectivity, increase the absorption coefficient of sunlight;

[0062] Diffusion of phosphorus oxychloride on the p-type crystalline silicon substrate to form a phosphorus concentration of 10 15 cm -3 The n-type layer;

[0063] Using PVD, that is, magnetron sputtering, a silicon monoxide film with a thickness of 100nm is prepared on the substrate with a silicon m...

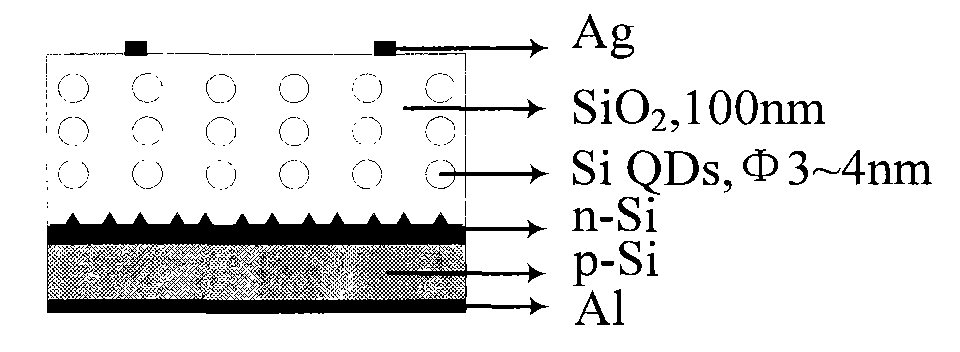

Embodiment 3

[0069] Prepare p-type (100) crystalline silicon with a thickness of 200um, and its boron doping concentration is 10 15 cm -3 , with a resistivity of 5 ohm cm, used as a substrate after cleaning with a standard semiconductor process;

[0070] On the p-type crystalline silicon substrate, sodium silicate Na with a mass fraction of 1.6% 2 SiO 3 , Sodium hydroxide NaOH with a mass fraction of 2.0% and isopropanol IPA solution with a volume fraction of 6% for texturing, that is, a water bath at 78°C to 83°C for 25 minutes to form a surface pyramid structure with a height of 6um to 8um to reduce the solar cell Surface reflectivity, increase the absorption coefficient of sunlight;

[0071] Diffusion of phosphorus oxychloride on the p-type crystalline silicon substrate to form a phosphorus concentration of 10 15 cm -3 The n-type layer;

[0072] Using PVD, that is, the method of magnetron sputtering, a silicon monoxide film with a thickness of 100nm is prepared on the substrate wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com