Preparation method of anion-exchange membranes based on ionic liquid

A technology of anion exchange membrane and ionic liquid, applied in the field of ion exchange membrane, can solve the problems of low conductivity, etc., and achieve the effects of good stability, simple process, good thermal stability and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 0.01mol of 1-allyl-3-methyl imidazole chloride, 0.0167mol of methyl methacrylate, 5mL of N,N-dimethylformamide and 0.25g of azobisisobutyronitrile into a three-necked flask , under the protection of nitrogen, placed in a water bath temperature of 45 ° C, stirred and refluxed for 30 h. The obtained copolymer was precipitated and washed with methanol several times, and dried for future use. Fully dissolve 1 g of the obtained copolymer in 20 mL of N,N-dimethylformamide, and let stand to defoam. After defoaming, the polymer solution was dried in a vacuum oven at 60°C for 24 hours to remove the solvent to form a chloride-type anion exchange membrane.

[0028] The resulting chloride-type anion exchange membrane was placed in 1mol L -1 Soak in NaOH solution for 24h, wait for Cl - completely converted to OH - Finally, remove the residual NaOH solution with deionized water and soak for 72 hours to obtain a hydroxide-type anion exchange membrane.

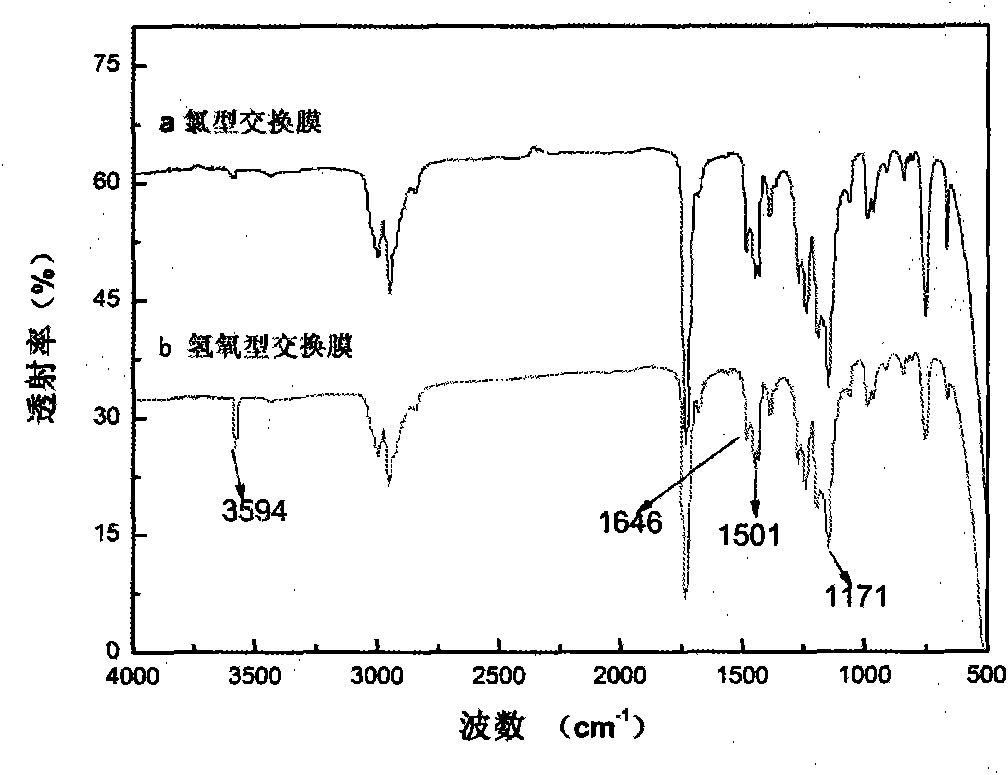

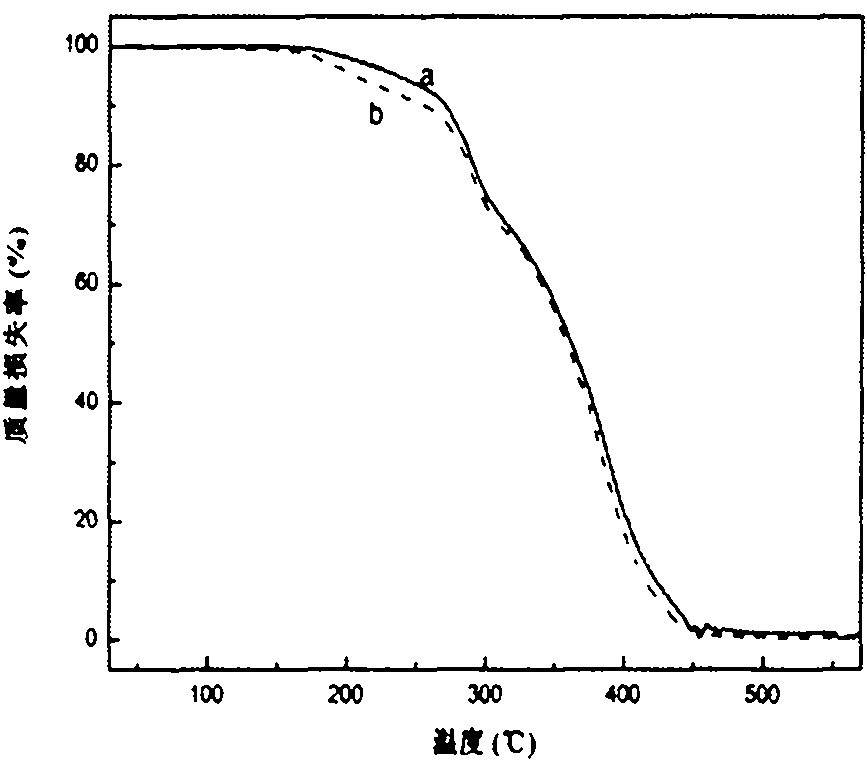

[0029] FT-IR 740SX sp...

Embodiment 2

[0041] Add 0.01 mol of 1-allyl-3-methyl imidazole bromide, 0.0125 mol of methyl methacrylate, 6 mL of chloroform and 0.20 g of azobisisobutyronitrile into a three-necked flask, under the protection of argon , placed in a water bath temperature of 50°C, stirred and refluxed for 25h. The obtained copolymer was precipitated and washed with ethanol several times, and dried for future use. Fully dissolve 1 g of the obtained copolymer in 15 mL of N,N-dimethylacetamide, and let it stand for defoaming. After defoaming, the polymer solution was dried in a vacuum oven at 70°C for 20 hours to remove the solvent to form a bromine-type anion exchange membrane.

[0042] The resulting bromine-type anion-exchange membrane was placed in 2mol L -1 Soaked in KOH solution for 24h, when the Br - completely converted to OH - Finally, remove the residual KOH solution with deionized water and soak for 72 hours to obtain a hydroxide-type anion exchange membrane.

[0043] The IEC of this film at r...

Embodiment 3

[0045] Add 0.01mol of 1-allyl-3-methyl imidazole chloride, 0.0250mol of butyl methacrylate, 7mL of toluene and 0.30g of benzoyl peroxide in a three-necked flask, under the protection of argon, Placed in a water bath temperature of 55°C, stirred and refluxed for 20h. The obtained copolymer was precipitated and washed with ethanol several times, and dried for future use. Fully dissolve 1 g of the obtained copolymer in 30 mL of tetrahydrofuran, and let it stand for defoaming. After defoaming, the polymer solution was dried in a vacuum oven at 60°C for 24 hours to remove the solvent to form a chloride-type anion exchange membrane.

[0046] Place the resulting chloride-type anion exchange membrane in a 3mol L -1 Soak in NaOH solution for 24h, wait for Cl - completely converted to OH - Finally, remove the residual NaOH solution with deionized water and soak for 72 hours to obtain a hydroxide-type anion exchange membrane.

[0047] The IEC of this film at room temperature is 0.19...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Methanol permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com