Monolithic catalysts used for preparing dimethyl ether by using synthesis gas, preparation method and application

A monolithic catalyst and synthesis gas technology, applied in physical/chemical process catalysts, dehydration of hydroxyl-containing compounds to prepare ethers, chemical instruments and methods, etc., can solve problems such as poor stability, high reaction temperature, low catalyst activity, etc., to achieve reaction The effect of low temperature, high catalytic activity, and excellent mass and heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] (1) Preparation of catalyst

[0035] The preparation method of the monolithic catalyst directly preparing dimethyl ether from synthesis gas provided by the invention comprises the following steps successively:

[0036] ① Treatment of the honeycomb ceramic carrier: the honeycomb ceramic carrier with a size of 12×12×50mm is treated with HNO with a mass concentration of 30-65%. 3 Soak for 1-4h, take it out and wash it with deionized water until PH = 7.0, dry and roast to obtain HNO 3 Processed honeycomb ceramic carrier;

[0037] ② Loading γ-Al 2 o 3 Preparation of the coated honeycomb ceramic carrier: the HNO obtained in step ① 3 The treated honeycomb ceramic carrier is immersed in 50ml of aluminum sol with a solid content of 5-20wt%, and put into a vacuum oven to pump until the glue liquid level rises to close to the mouth of the beaker, stop vacuuming, take it out after 30s, and remove the aluminum sol on the surface. Rinse the sol with deionized water, blow out the...

Embodiment 1

[0058] (1) Cut the commercially available 400 holes / square inch honeycomb ceramics into cube-shaped samples of 12mm×12mm×50mm, and use 65wt%HNO 3 Soak for 2 hours, then wash with deionized water until the filtrate is neutral, dry at 110°C for 12 hours, and bake at 500°C for 4 hours to obtain the pretreated honeycomb ceramic substrate.

[0059] (2) Immerse the pretreated honeycomb ceramic substrate in 50ml of aluminum sol with a solid content of 10wt%, and put it into a vacuum oven to pump until the glue liquid level rises to close to the mouth of the beaker, stop vacuuming, and take it out after 30s. Rinse the aluminum sol on the surface of the carrier with deionized water, blow out the residual glue in the channel with 0.3MPa compressed air, dry at 110°C for 12h, and bake at 500°C for 4h, that is, the γ-Al is loaded 2 o 3 Coated honeycomb ceramic substrates.

[0060] (3) 48.3g Cu(NO 3 ) 2 ·3H 2 O, 24.3g Zn(NO 3 ) 2 ·6H 2 O and 17.4gAl(NO 3 ) 3 9H 2 O was dissolved ...

Embodiment 2

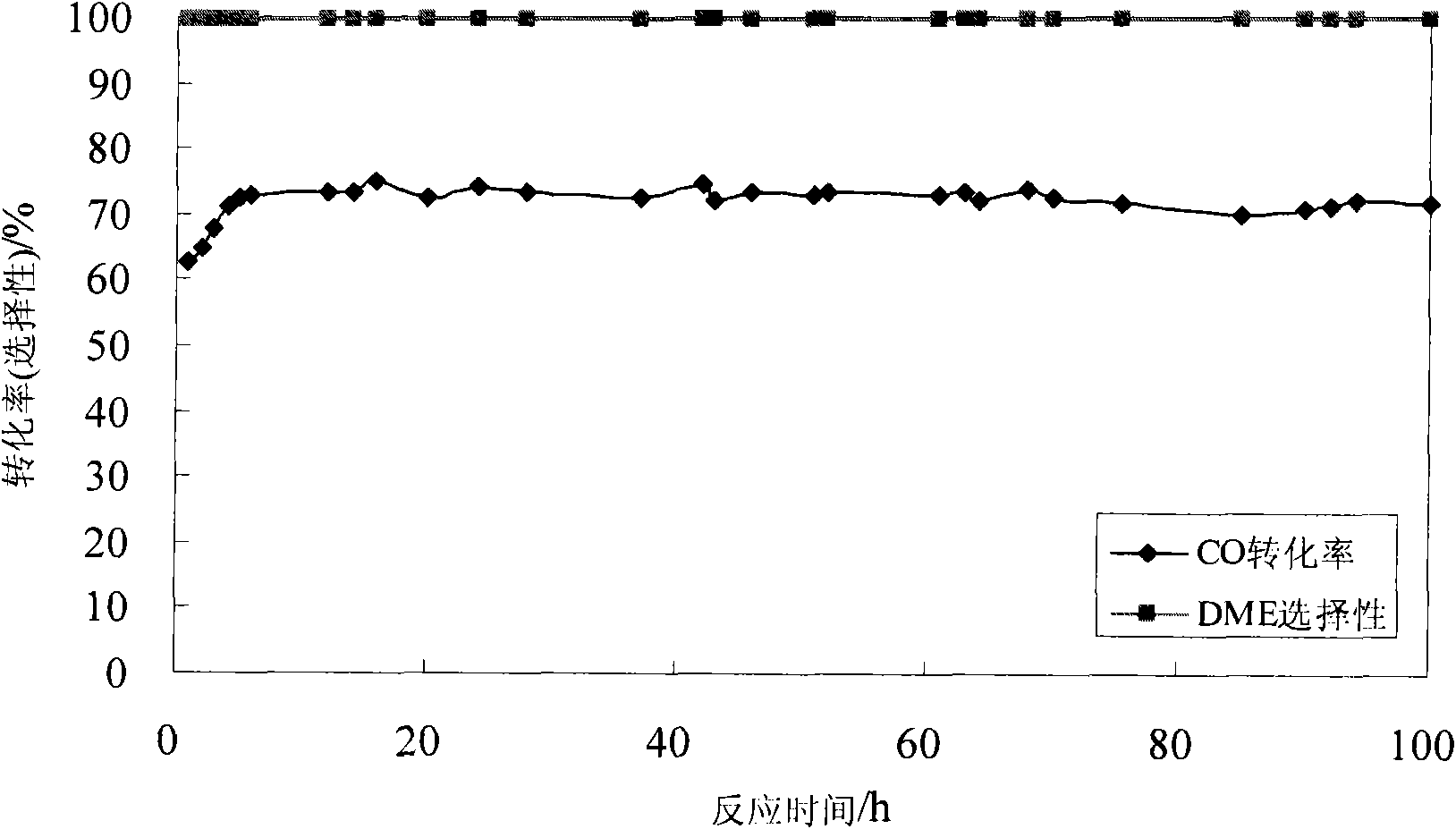

[0065] The preparation method of the monolithic catalyst is the same as in Example 1, except that the reaction conditions in step (6) are: temperature 250°C, pressure 4.0MPa, space velocity 1500h -1 , and under this reaction condition, the catalytic performance of the catalyst was evaluated for 100h, and the evaluation results are shown in figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com