Fireproof anti-ultraviolet anti-static ABS material and preparation method thereof

An ABS material and antistatic technology, which is applied in the field of ABS material and its preparation, can solve the problems of shortened service life of helmets, material properties, accelerated material aging, etc., and achieves the effect of delaying heat transfer, improving performance and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

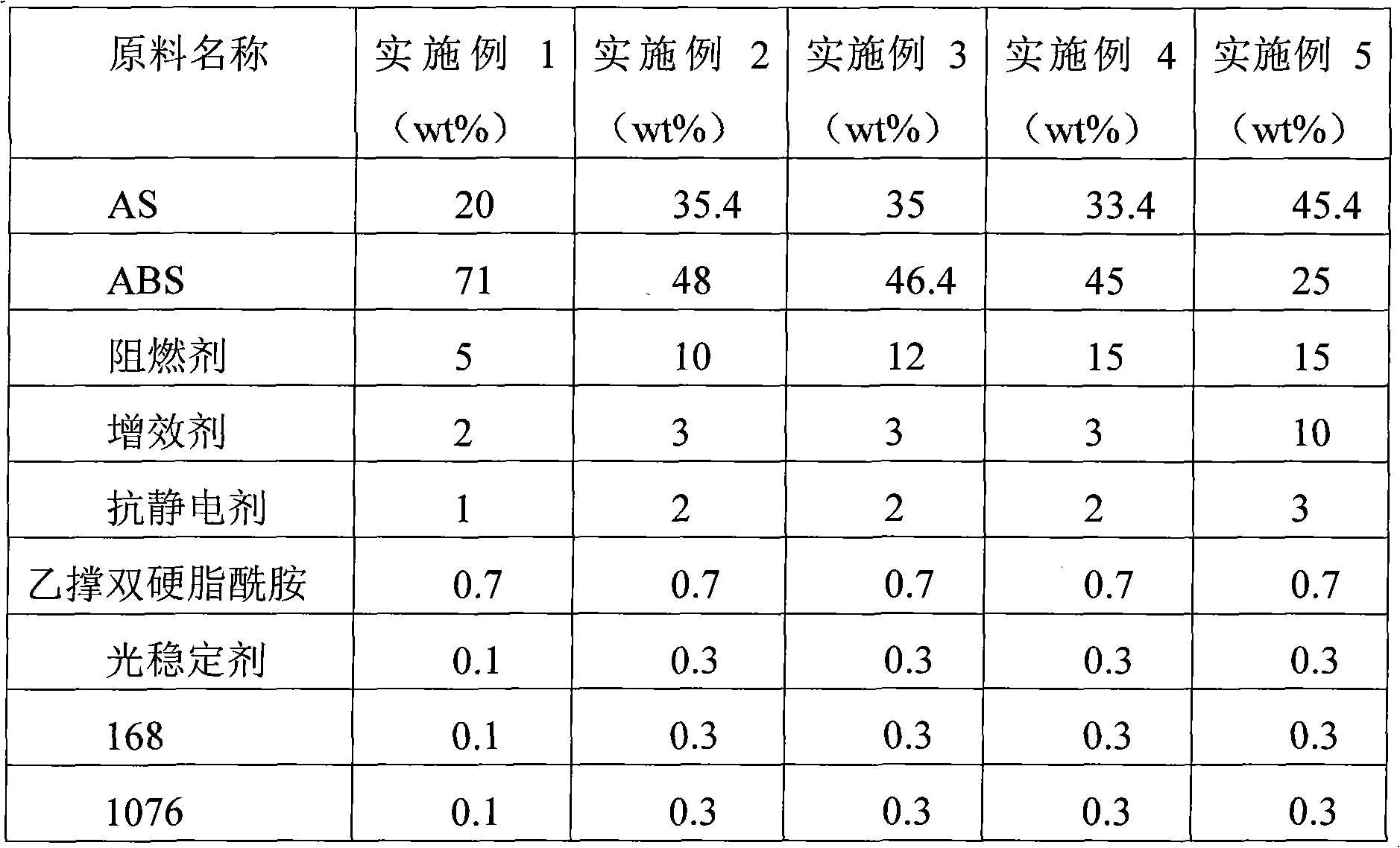

Embodiment 1-5

[0047]

[0048] Put all the components into a high mixer in proportion and add 0.2wt% white oil of the total weight of raw materials and mix for 4 minutes, then extrude and granulate with a screw extruder, the processing temperature is 245°C, and the screw speed is 450 rpm point.

[0049] The flame retardant includes chlorinated polyethylene (CPE) dispersed nano fillers, that is, CPE is dispersed and added with 0.3% organically modified montmorillonite; the synergist is antimony trioxide, antimony acid A mixture of sodium and sodium metaborate; the antistatic agent is a mixture of sodium dodecylbenzenesulfonate and ethoxylated octadecylamine.

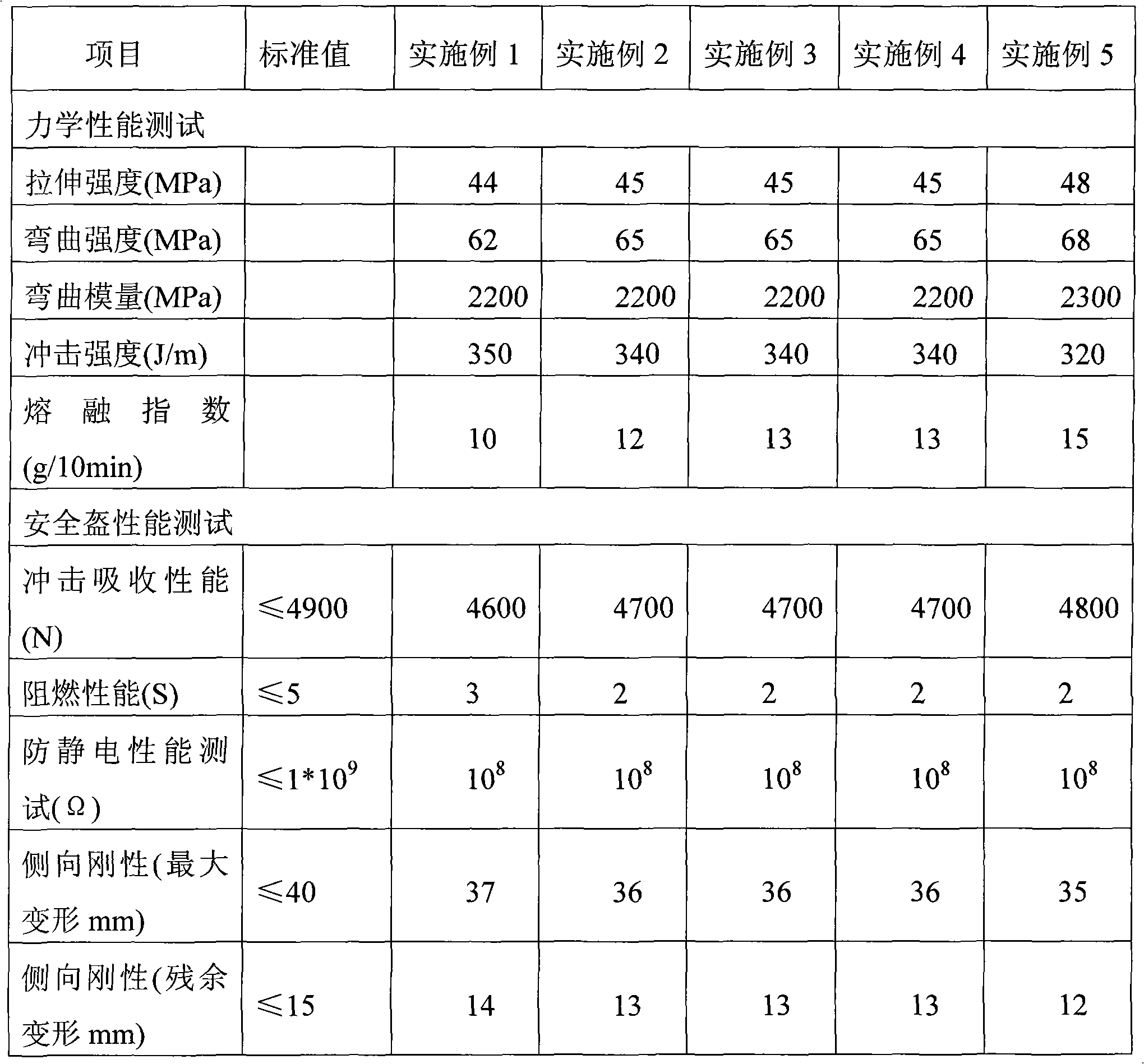

[0050] According to the sample physical property comparison that embodiment 1-5 makes:

[0051] Method A should be preferred for ultraviolet irradiation pretreatment, and method B can be used when the user requires or is otherwise necessary.

[0052] When using external ray irradiation (A method), the helmet should be irradiated wi...

Embodiment 6

[0059] A preparation method of a fireproof, ultraviolet-proof and antistatic ABS material, the method comprising the steps of:

[0060] (1) Take raw material ABS 45wt%, acrylonitrile content is the copolymer AS 30.8wt% of styrene and acrylonitrile of 35%, flame retardant 10wt%, synergist antimony trioxide and sodium borate mixture 8wt%, Antistatic agent 5wt%, lubricant ethylene bisstearamide 0.1wt%, antioxidant 1681wt%, light stabilizer hydroxybenzophenone 0.1wt%;

[0061] The ABS is a product with a trimodal particle size structure compounded by emulsion polymerized ABS and bulk polymerized ABS at a weight ratio of 90:10. The emulsion polymerized ABS is prepared by emulsion grafting, and its rubber diameter is 0.2 μm, bulk polymerized ABS is a bulk ABS with bimodal particle size distribution prepared by bulk method technology, one particle size peak is 0.5 μm, and the other particle size peak is 1.2 μm.

[0062] The flame retardant includes CPE-dispersed nanofillers, and the...

Embodiment 7

[0066] A preparation method of a fireproof, ultraviolet-proof and antistatic ABS material, the method comprising the steps of:

[0067] (1) Take raw material ABS 50.9wt%, acrylonitrile content is 25% copolymer AS of styrene and acrylonitrile 23wt%, flame retardant 10wt%, synergist antimony trioxide and sodium borate mixture 8wt%, Antistatic agent 4wt%, lubricant ethylene bisstearamide 3wt%, antioxidant 168 0.1wt%, light stabilizer hydroxybenzophenone 1wt%;

[0068] The ABS is a product with a trimodal particle size structure compounded by emulsion polymerized ABS and bulk polymerized ABS at a weight ratio of 30:70. The emulsion polymerized ABS is prepared by emulsion grafting, and its rubber particle size is 0.5μm, bulk polymerized ABS is a bulk ABS with bimodal particle size distribution prepared by bulk method technology, one particle size peak is 0.7 μm, and the other particle size peak is 0.9 μm.

[0069] The flame retardant includes CPE dispersed nanofillers, and the CPE...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com