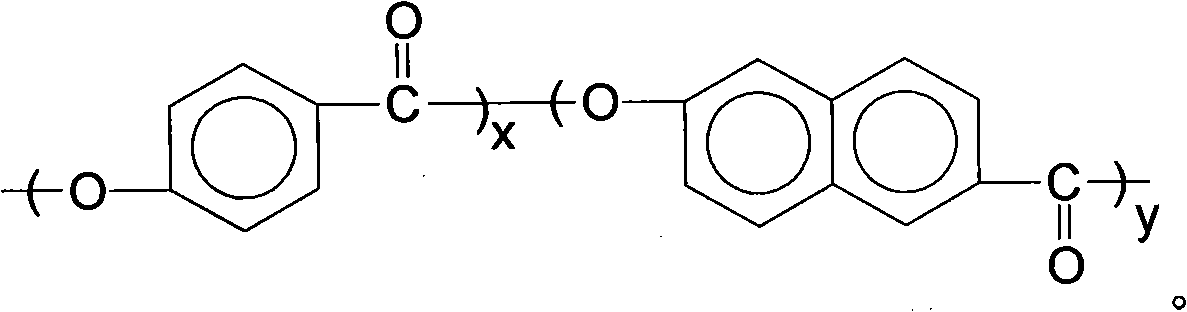

Method for preventing ultraviolet ageing of Vectran fibers

A fiber and ultraviolet technology, which is applied in fiber treatment, fiber type, textile and papermaking, etc., can solve the problems of Vectran fiber's poor anti-ultraviolet aging effect, and achieve the effect of alleviating photoaging, good protection, and reducing etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

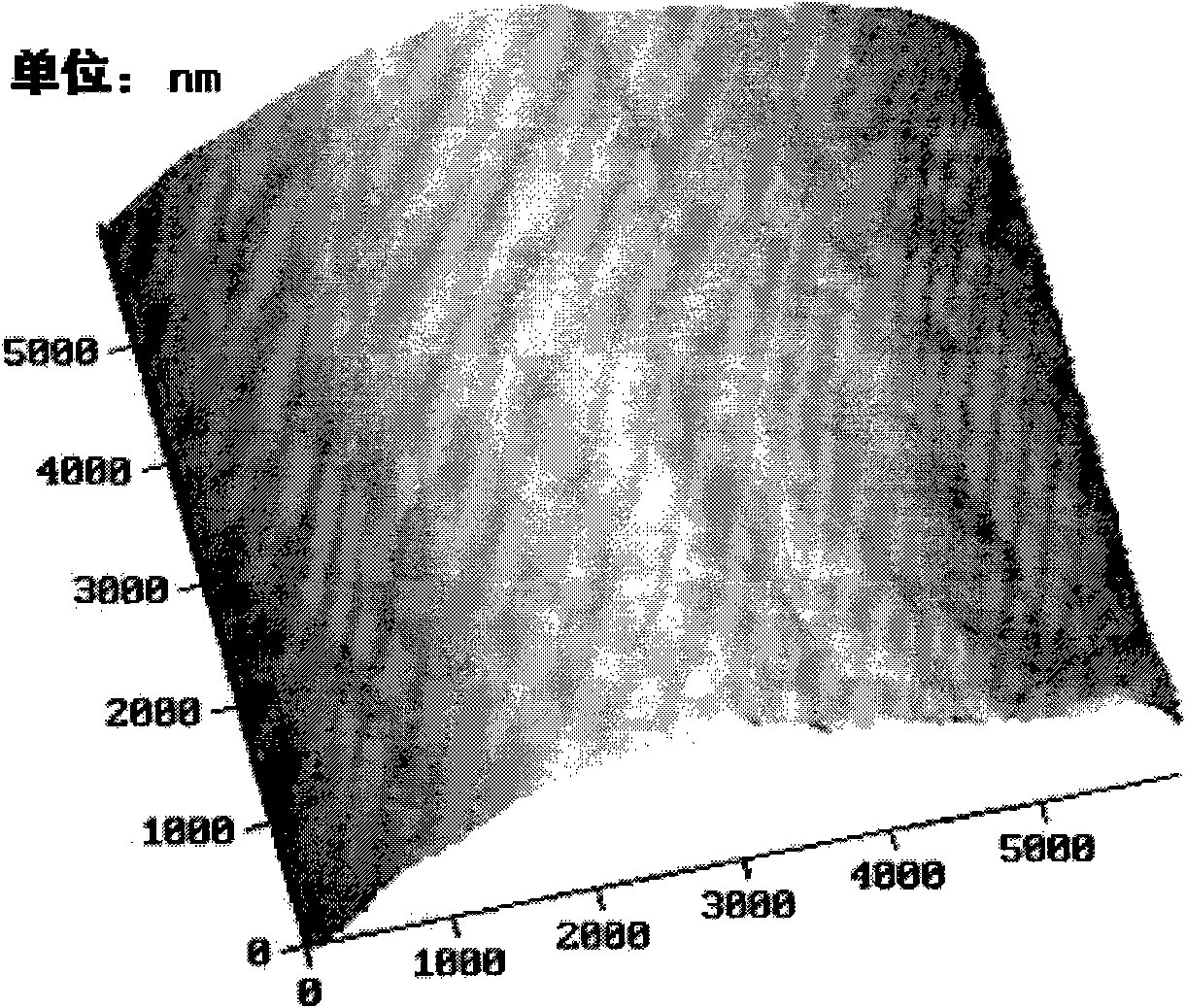

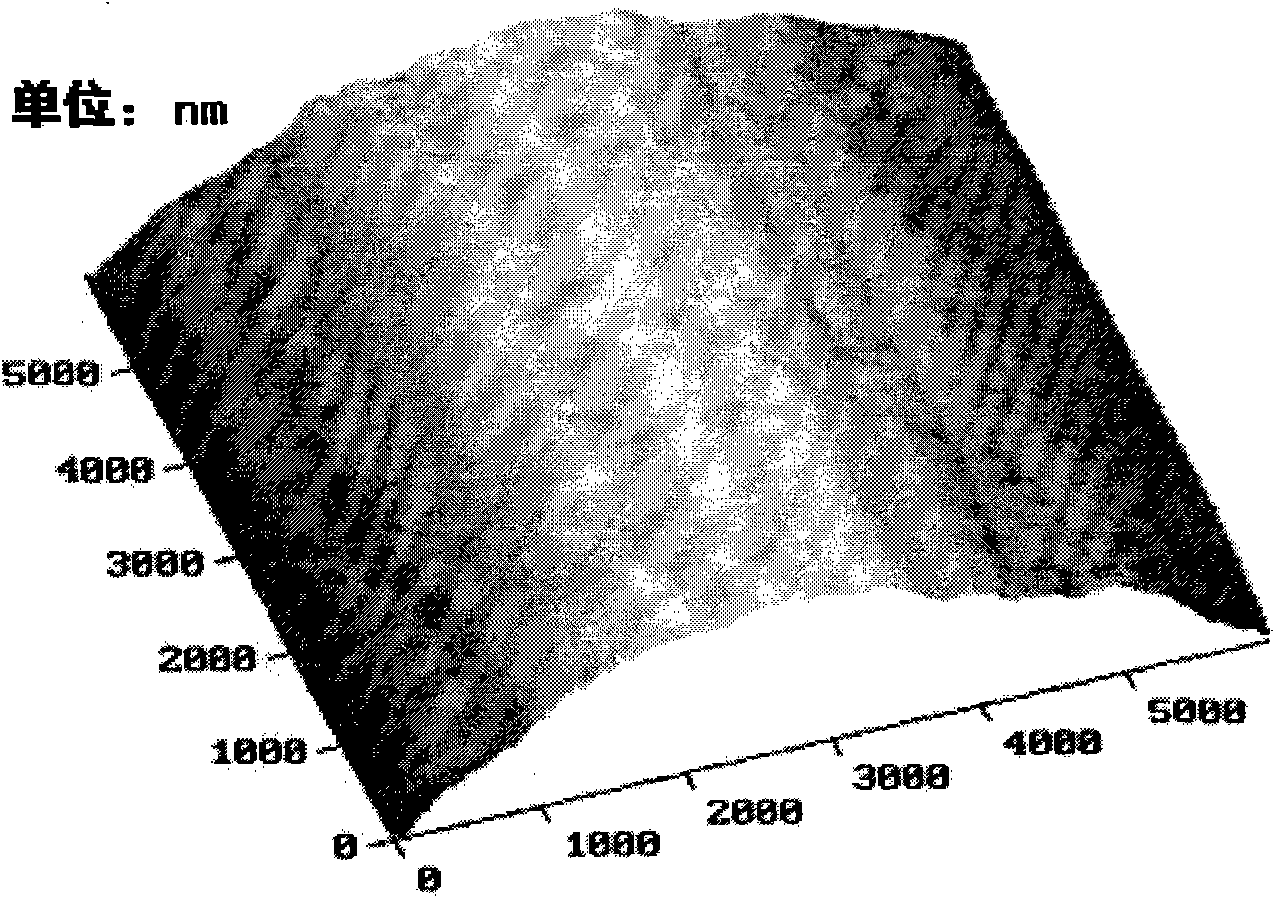

[0017] Specific Embodiment 1: The method for protecting Vectran fiber from ultraviolet aging in this embodiment is realized through the following steps: 1. Prepare TiO with a molar concentration of Ti element of 0.25-0.8 mol / L by sol-gel method 2 Hydrosol; Two, to the TiO that step one obtains 2 Add an organic solution of an organic absorbent to the hydrosol, and stir for 30-50 minutes to obtain a polymer coating, wherein the organic absorbent is salicylate, benzophenone, benzotriazole, substituted triazine or substituted Acrylonitrile, TiO 2 The volume ratio of the hydrosol to the organic solution of the organic absorbent is 0.2 to 0.7: 1, and the mass concentration of the organic absorbent in the organic solution of the organic absorbent is 0.1% to 10%; Then apply ultrasound to the polymer coating, take out the Vectran fibers after ultrasonic vibration for 20-30 minutes, and then dry them at room temperature, then put the Vectran fibers in an oven at 70-85°C, keep them dry ...

specific Embodiment approach 2

[0021] Specific embodiment two: the difference between this embodiment and specific embodiment one is that TiO in step one 2The preparation method of the hydrosol is: mix tetrabutyl titanate and glacial acetic acid in a molar ratio of 1:4, stir magnetically for 30-60 minutes to obtain a mixed solution, and then add the mixed solution to 0.05mol / L hydrochloric acid solution , after magnetic stirring at room temperature for 30 to 60 minutes, then placed in a water bath at 50 to 60°C and magnetically stirred for 30 to 50 minutes, then cooled naturally, and then aged at room temperature for 7 to 10 days to obtain TiO 2 Aqueous sol; wherein the molar ratio of tetrabutyl titanate to the volume of hydrochloric acid solution is 1mol: 2-4L. Other steps and parameters are the same as those in Embodiment 1.

[0022] The TiO prepared by this embodiment 2 The molar concentration of Ti element in the hydrosol is 0.25-0.5 mol / L.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment is different from Embodiment 2 in that it is placed in a 50° C. water bath and stirred magnetically for 30 minutes. Other steps and parameters are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com