Rapid determining method of COD by photocatalytic digestion

A rapid determination and photocatalytic technology, applied in the direction of material excitation analysis, etc., can solve the problems of unsuitable rapid determination, influence on optical detection, and difficult preparation, etc., and achieve the effect of improving oxidation efficiency, easy operation of the method, and high reaction sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

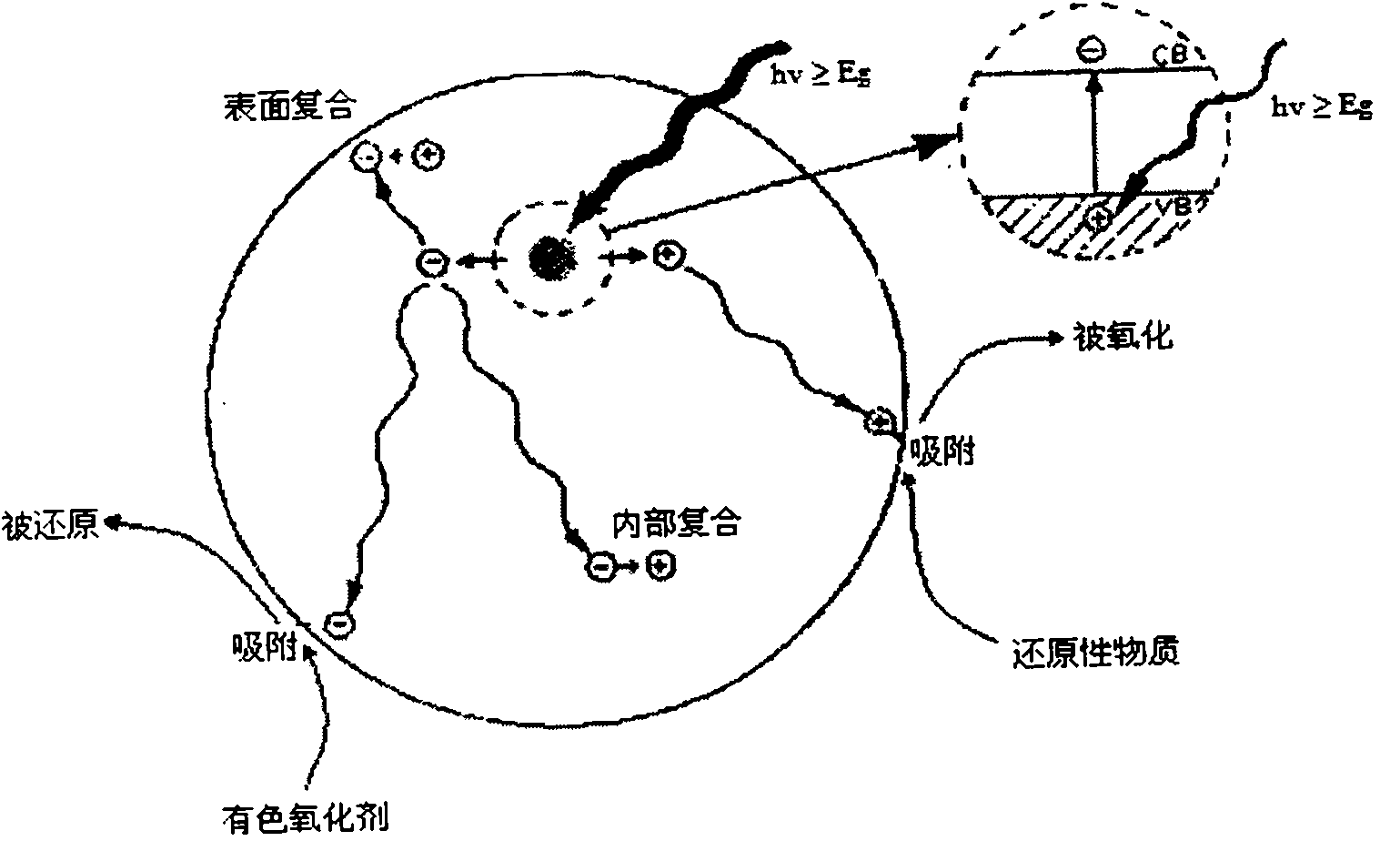

Method used

Image

Examples

Embodiment 1

[0021] The comparison of the inventive method and the national standard dichromate method oxidation rate and the mensuration of actual water sample and simulated water sample:

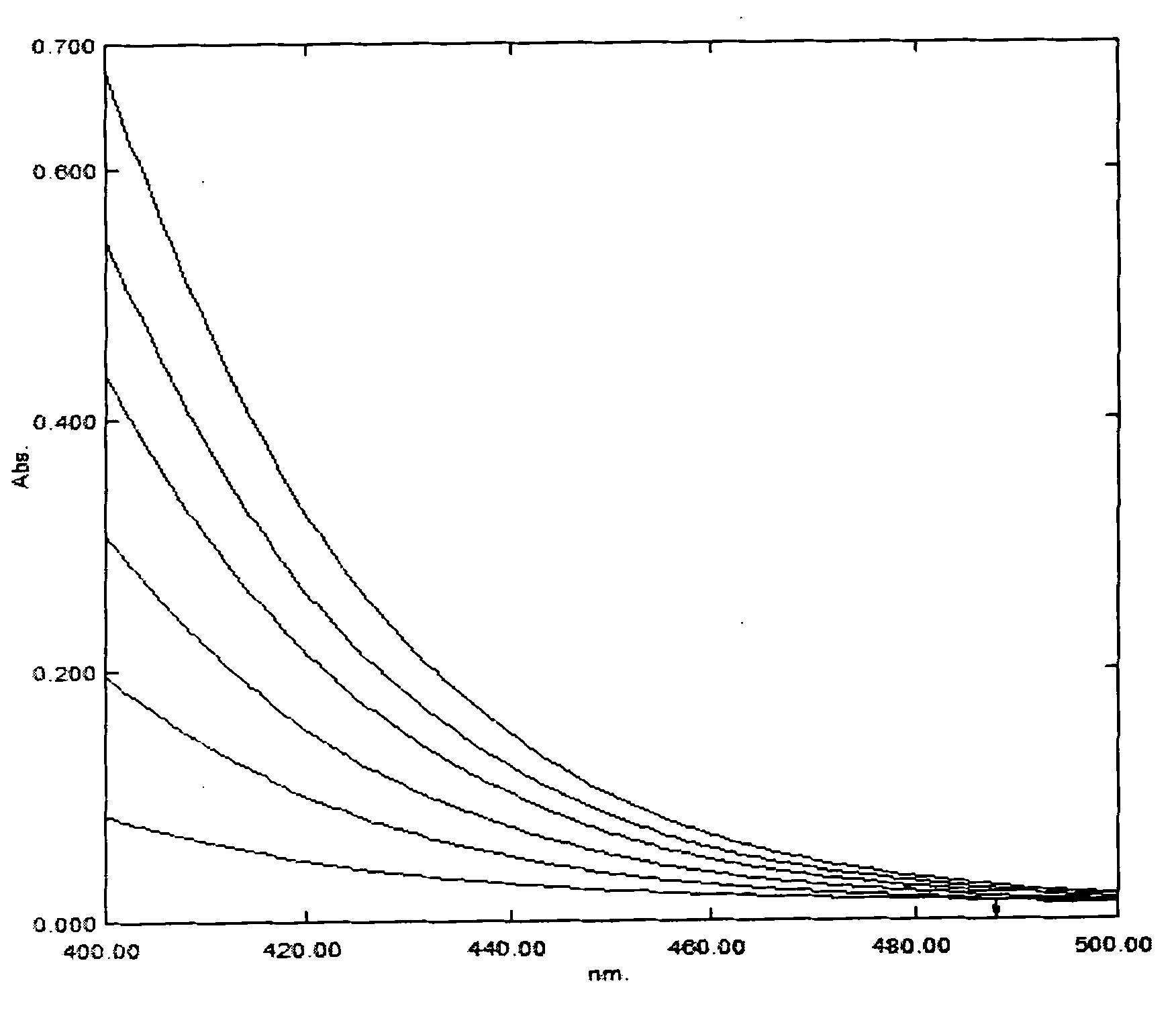

[0022] In the present embodiment, the concentration of nano photocatalyst is 0.003g / L and the particle size is 5nm TiO 2 Powder, the colored oxidant is Ce(SO 4 ) 2 , the acidic medium uses H with a concentration of 1mol / L 2 SO 4 , the three form a composite system. At room temperature, use a 3W low-power ultraviolet light to illuminate the water sample for 10 minutes after oxidation and digestion for spectral detection. The scanning spectrum is shown in the attachment figure 1 , with 1-20mg / L potassium hydrogen phthalate solution as the standard solution, establish a standard curve, and measure the COD value of the sample.

[0023] The higher the oxidation rate of the oxidative digestion method, the more complete the oxidative digestion of the water sample, and the closer the measurement result is ...

Embodiment 2

[0038] This embodiment measures the actual water sample and the simulated water sample:

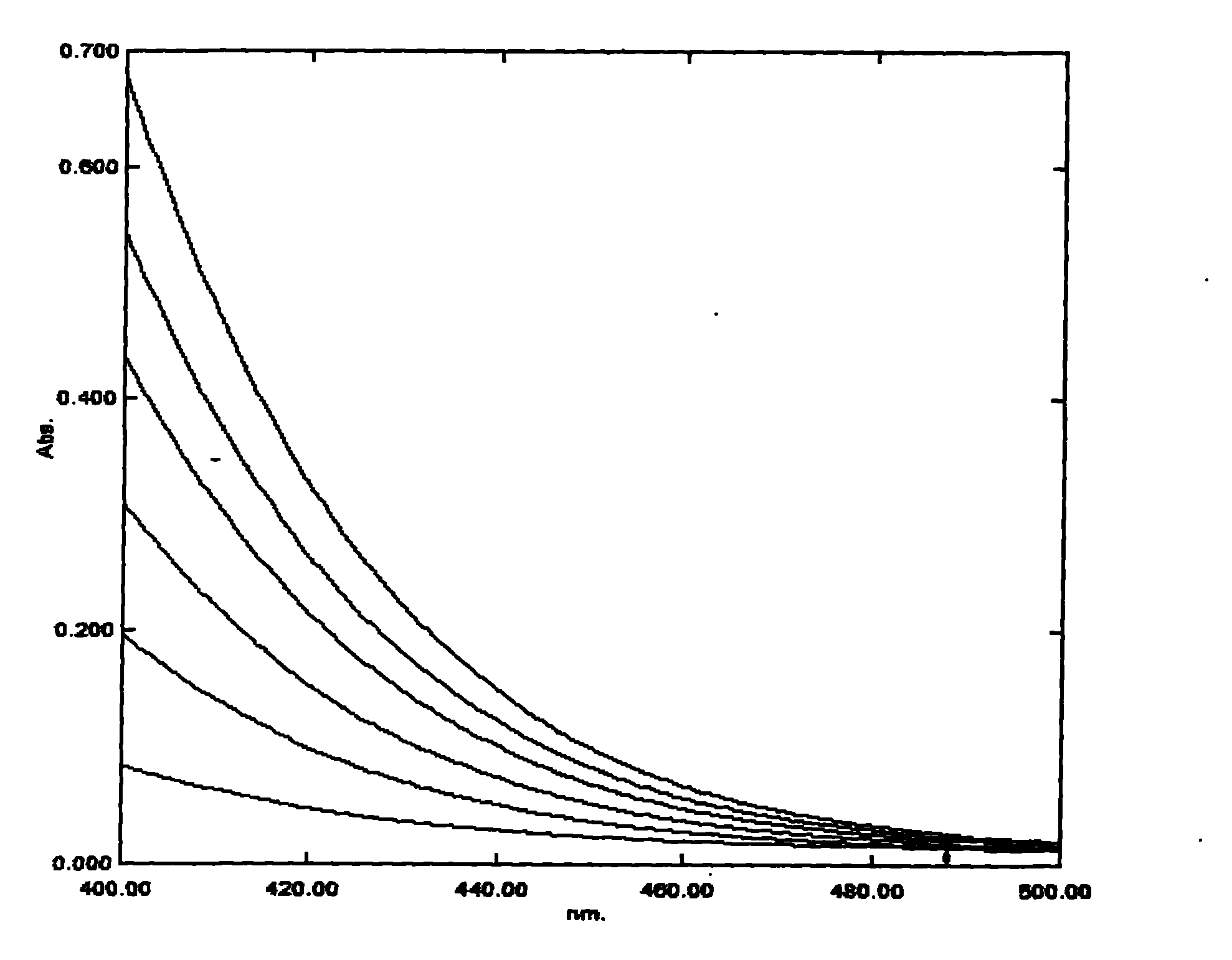

[0039] In the present embodiment, the concentration of nano photocatalyst is 0.030g / L and the particle size is 5nm TiO 2 Powder, colored oxidant chooses KMnO with a concentration of 0.4mmol / L 4 , the acidic medium uses H with a concentration of 1mol / L 2 SO 4 , the three form a composite system. Under room temperature, use a 3W low-power ultraviolet light to irradiate, oxidize and digest the water sample for 10 minutes, then perform spectral detection, and use 1-60mg / L potassium hydrogen phthalate solution as the standard solution to establish The standard curve was used to determine the COD value of the sample.

[0040] Chloride ion (Cl - ) has obvious interference to some COD determination methods, such as the national standard dichromate method, it is necessary to add a masking agent to eliminate Cl - interference. Using this system for Cl - Concentration of 15mg / L simulated wate...

Embodiment 3

[0054] This embodiment measures the actual water sample and the simulated water sample:

[0055] In the present embodiment, the concentration of nano photocatalyst is 0.030g / L and the particle size is 5nm TiO 2 Powder, the colored oxidizing agent chooses K with a concentration of 4.8mmol / L 2 Cr 2 o 7 , the acidic medium uses H with a concentration of 1mol / L 2 SO 4 , the three form a composite system. At room temperature, use a 3W low-power ultraviolet light to irradiate, oxidize and digest the water sample for 10 minutes, and perform spectral detection. Using 1-35 mg / L potassium hydrogen phthalate solution as the standard solution, the establishment The standard curve was used to determine the COD value of the sample.

[0056] Chloride ion (Cl - ) has obvious interference to some COD determination methods, such as the national standard dichromate method, it is necessary to add a masking agent to eliminate Cl - interference. Using this system for Cl - Concentration of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com