Technology of making yellow wine by grinding and pulping rice raw material and performing high-temperature continuous steaming

A rice and pulp refining technology, which is applied in the preparation of alcoholic beverages, methods based on microorganisms, biochemical equipment and methods, etc., can solve the problems of large man-hour requirements, high labor intensity, and large steam loss, and achieve easy pipeline transportation , High degree of mechanization, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

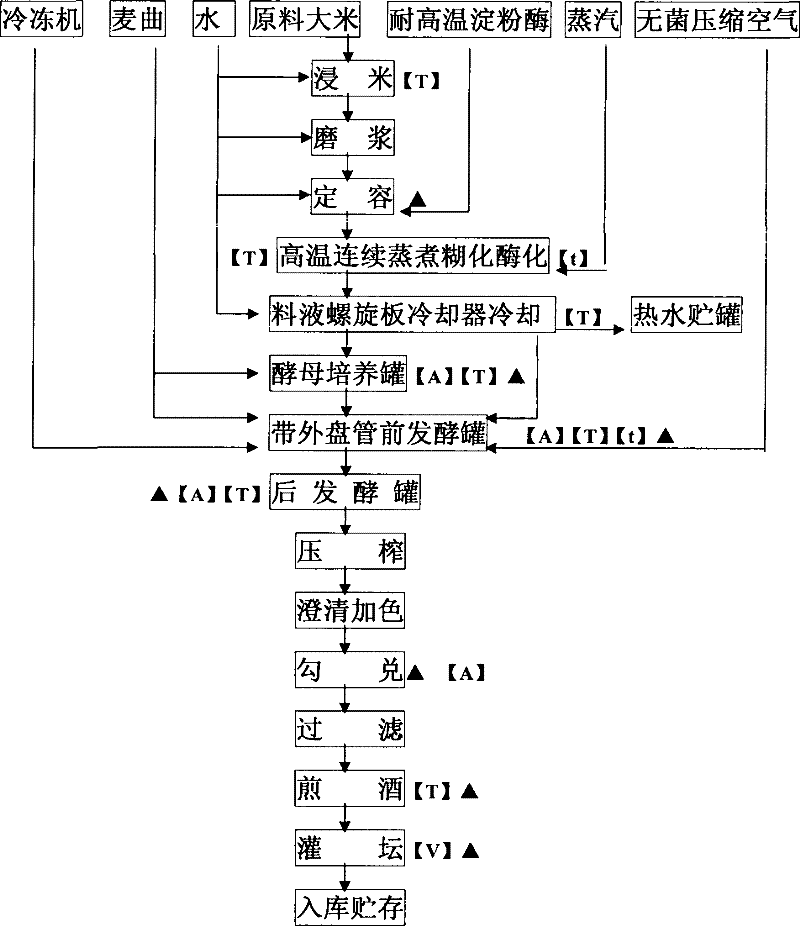

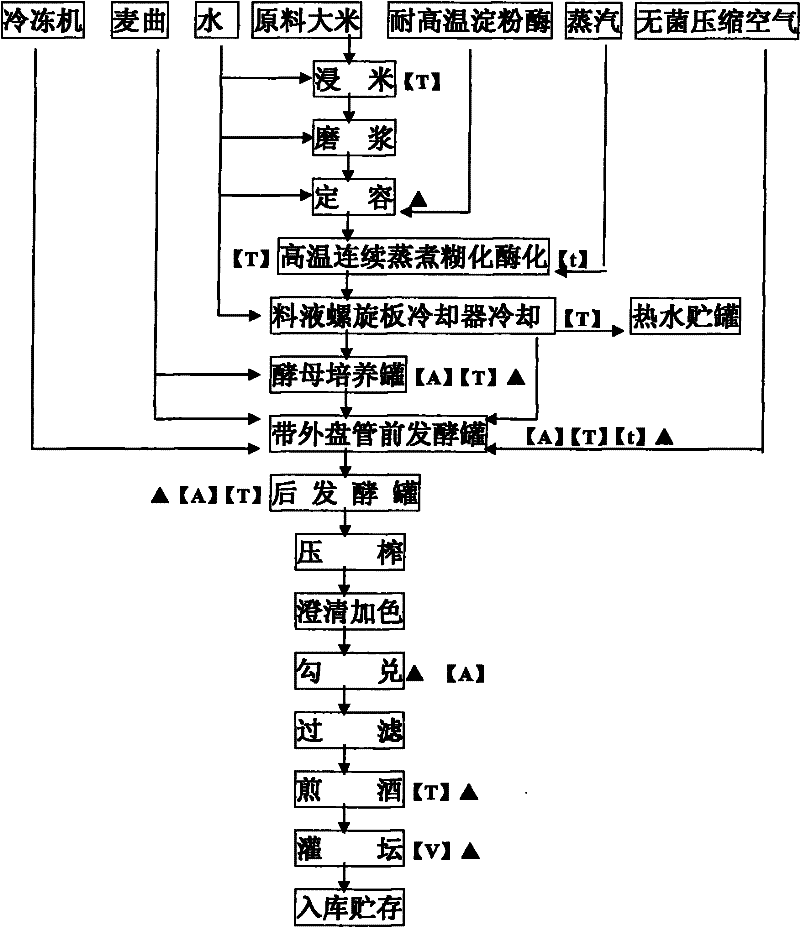

[0031] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0032] As shown in the figure, this process of crushing and refining raw rice and using high-temperature continuous cooking to brew rice wine specifically includes the following steps:

[0033] (1) Rice crushing and refining continuous cooking gelatinization enzymatic process

[0034] (1), constant volume: Soak the rice in water for 3 hours, grind the slurry water with a grinding wheel, add water according to the mass ratio of rice (dry): water = 1:2, and reach the specified scale of the constant volume tank, press 0.4 to 0.6 Add high-temperature-resistant amylase at a ratio of kg / (ton of dry rice input); stir evenly; the temperature range of amylase is 95--110°C.

[0035] (2) Through the steam material mixer and the maintenance pipeline, carry out high-temperature continuous cooking, gelatinization and enzymatic conversion: the temperature is 102-107 ° C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com