Method for preparing monoclinic phase vanadium dioxide and doped nano powder thereof

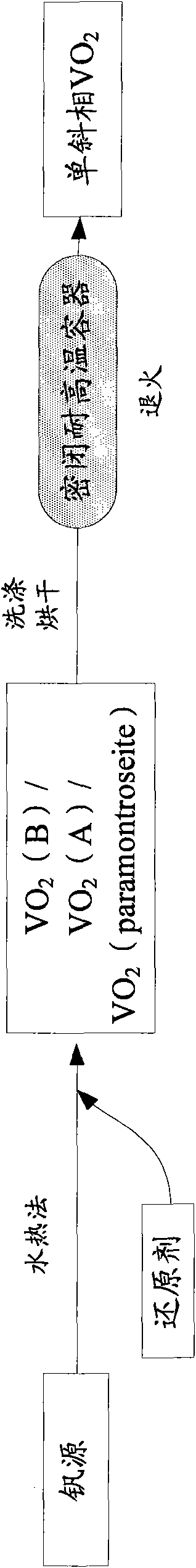

A kind of vanadium dioxide nanometer, monoclinic phase technology, applied in vanadium oxide and other directions, can solve the problems of industrial operation danger of combustion method, product purity is not particularly high, environment is not friendly, etc., to achieve superior intelligent infrared controllability, mature production equipment Simple, easy-to-industrial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

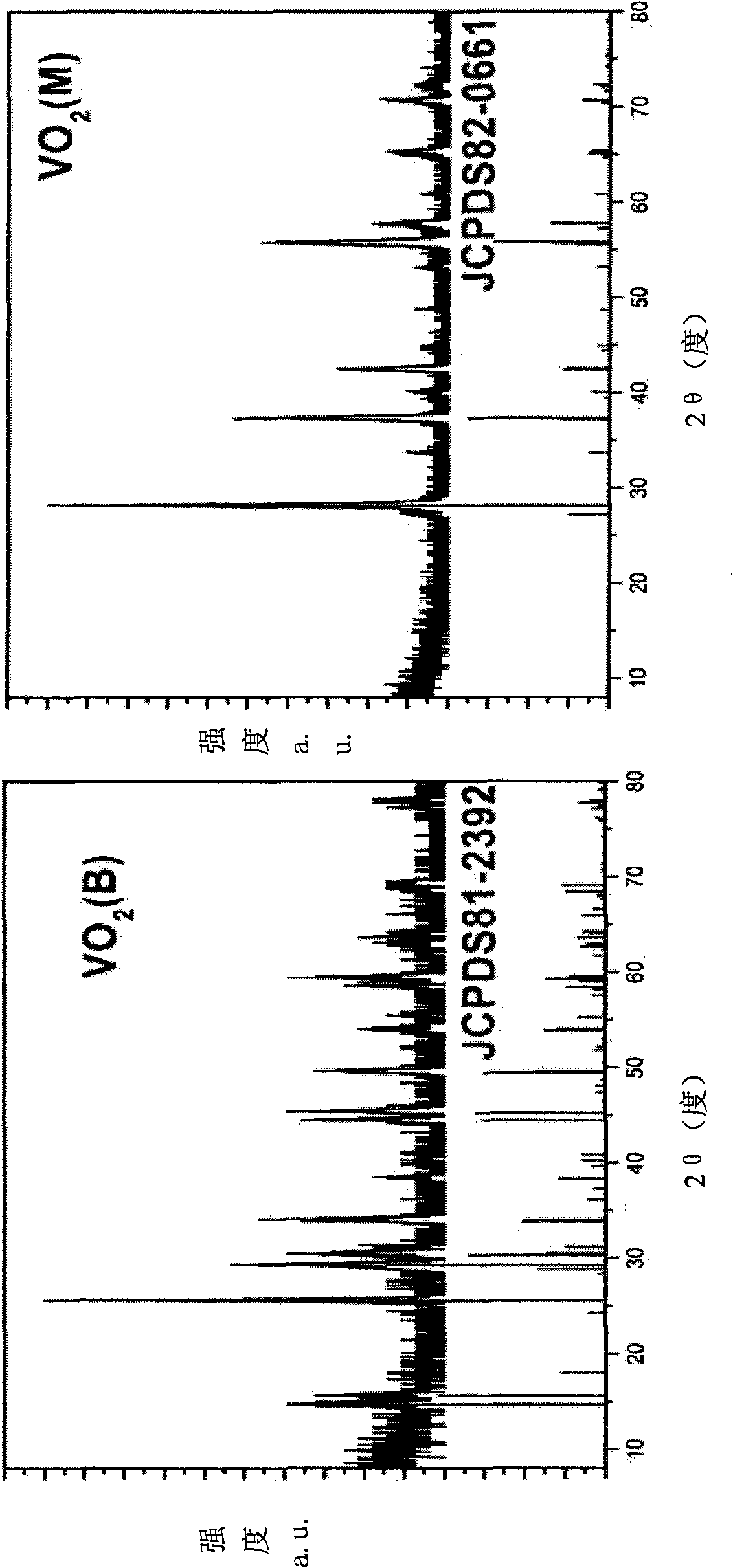

[0039] Embodiment 1 uses V0 2 (B) as a precursor

[0040] Add 5mmol V to a polytetrafluoroethylene reactor with a volume of 35ml 2 o 5 and 8mmolH 2 C 2 o 4 , then add 30ml of distilled water, stir for 30 minutes, put it into a metal kettle shell and seal it, then keep it at 200°C for 48 hours, after cooling down naturally, centrifuge the product, wash it with distilled water and industrial ethanol for 3 times, and then put the sample in a vacuum drying oven Bake at 60°C for 8 hours, then bake at 120°C for 4 hours to obtain dry VO 2 (B), then 1 g of dry VO 2 (B) Vacuum sealed into a glass tube with an inner diameter of 8mm, and annealed at 500°C for 20h to obtain pure VO 2 (M).

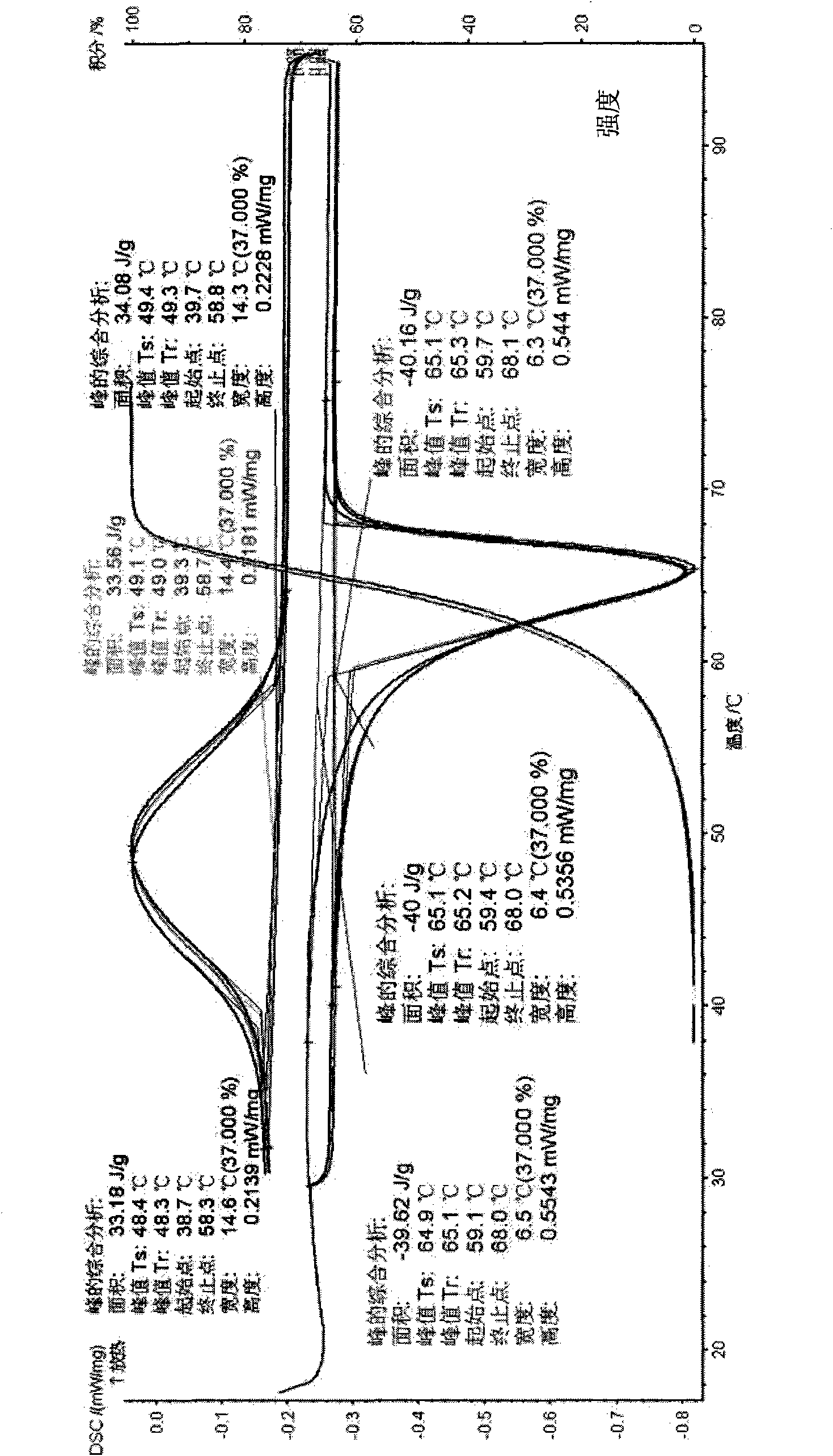

[0041] Its XRD and DSC charts are attached figure 2 and 3 , it can be seen from the figure that the obtained XRD peak intensity is particularly high and coincides well with the standard card spectrum, and the DSC peak area is large, indicating that the product has good crystallinity and high...

Embodiment 2

[0042] Example 2 uses VO 2(A) as a precursor

[0043] Add 3mmol VO(acac) in a polytetrafluoroethylene reactor with a volume of 55ml 2 and 50ml of distilled water, stirred for 30min, put into a metal kettle shell, and then kept at 220°C for 24h, after natural cooling, the product was taken off-line, washed with distilled water and industrial ethanol for 3 times, and then the sample was placed in a vacuum drying oven at 60°C Bake for 8 hours, and then bake for 4 hours at 120°C to obtain dry VO 2 (A), then 200mg dry VO 2 (B) Vacuum sealed into a glass tube with an inner diameter of 8mm, and annealed at 500°C for 20h to obtain pure VO 2 (M).

[0044] Its XRD and DSC charts are attached Figure 4 and 5 , it can be seen from the figure that the XRD of the obtained product is in good agreement with the standard spectrum, indicating that the product is pure VO 2 (M). attached Figure 6 It is the SEM picture of the morphology of the final product. It can be seen that the obtai...

Embodiment 3

[0045] Example 3 uses Mo-doped VO 2 (B) as a precursor

[0046] Add 2.25mmol V in a polytetrafluoroethylene reactor with a volume of 35ml 2 o 5 , 0.25mmolNa 2 MoO 4 and 4 mmol H 2 C 2 o 4 2H 2 O, then add 30ml of distilled water, stir for 30 minutes, put it into a metal kettle shell and seal it, then keep it at 200°C for 48 hours, after cooling down naturally, centrifuge the product, wash it with distilled water and industrial ethanol for 3 times, and then dry the sample in vacuum Baked at 60°C for 8 hours in an oven, and then baked at 120°C for 4 hours to obtain dry Mo-doped VO 2 (B), then 200 mg of dry Mo-doped VO 2 (B) Vacuum sealed into a glass tube with an inner diameter of 8mm, and annealed at 500°C for 20h to obtain Mo-doped VO 2 (M).

[0047] Its XRD and DSC charts are attached Figure 7 and 8 , it can be seen from the figure that the XRD and VO of the final product 2 (M) The standard spectrum is very consistent, and the DSC peak is also reduced to about ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com