Method for refining microbial organic fertilizer with branch lops

A bio-organic fertilizer and pruning technology, which is applied to the treatment of bio-organic parts, organic fertilizers, and the preparation of organic fertilizers. It can solve the problems of affecting soil structure, affecting the fermentation quality and effect of branch prunings, and difficult branch prunings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

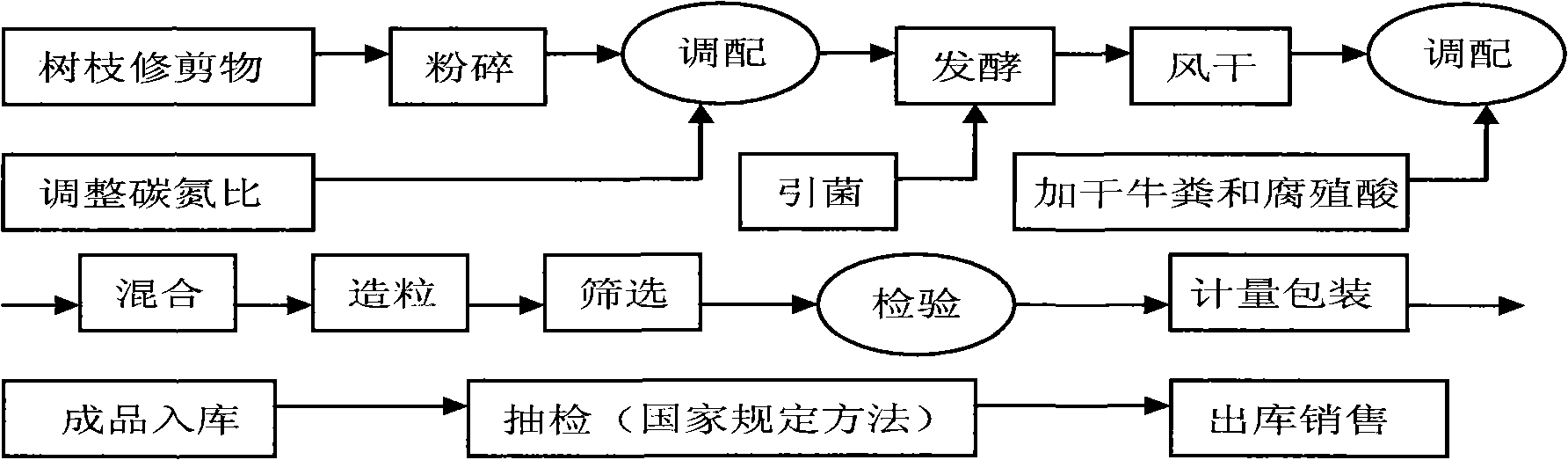

[0007] The specific embodiment of the present invention is referring to the following process flow chart, and its main implementation method and process are specifically stated

[0008]

[0009] The instructions are as follows:

[0010] 1). Crushing of branch prunings

[0011] Process requirements indicators: the particle size after the third stage crushing is 0.8-1.2mm

[0012] Operation method: The branches are chopped by blades for the first time and made into fragments or short sections, and then crushed for the second time. After 30 days of stacking and retting, the third time is crushed. The fineness is controlled by sieve plates to meet the optimum fermentation requirements. Excellent fineness (0.8-1.2mm particle size).

[0013] 2). Fermented and decomposed

[0014] Process requirements indicators: After fermentation and maturity, the carbon-to-nitrogen ratio is required to be ≤ 20, the appearance is loose, and there is a slight fragrance of leaves.

[0015] Oper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com