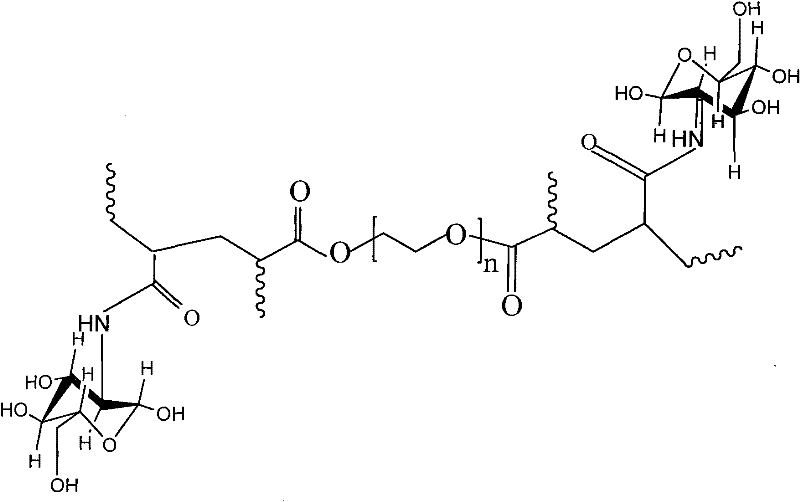

Glucosamine modified poly (ethylene glycol) diacrylate (PEGDA) hydrogel, preparation method and application thereof

A glucosamine and polyethylene glycol double technology is applied in the field of glucosamine modified polyethylene glycol diacrylate hydrogel and its preparation, which can solve the problem of lack of biological activity and cell recognition signal, unfavorable cell-specific gene activation, etc. problem, to achieve the effect of being conducive to large-scale production, good biocompatibility, and increasing secretion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

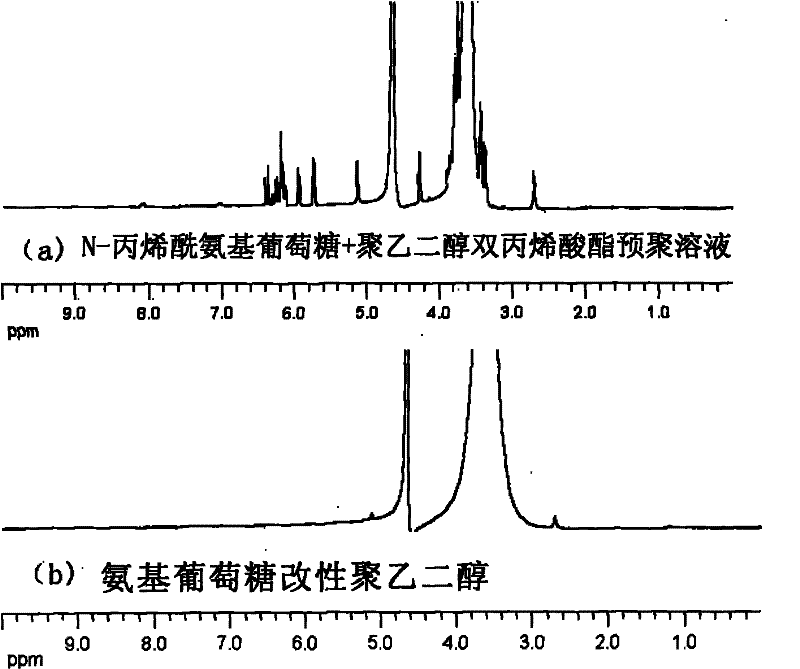

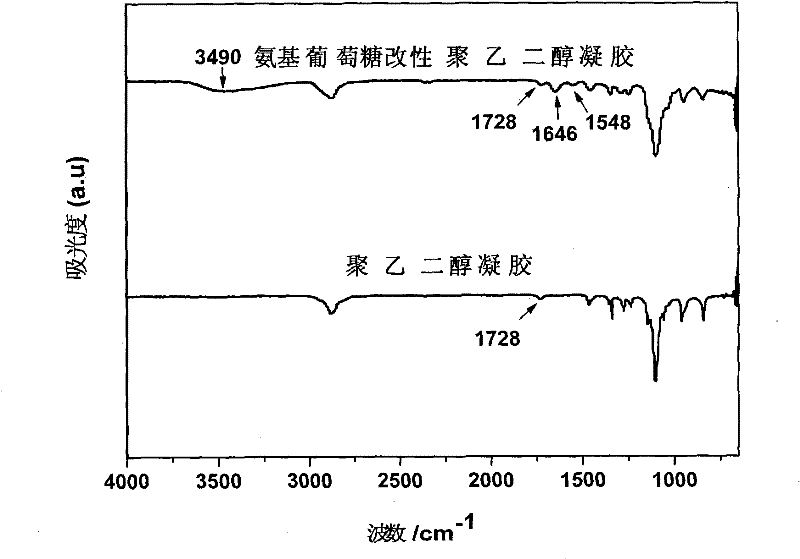

Method used

Image

Examples

Embodiment 1

[0040] The preparation of glucosamine modified PEGDA hydrogel comprises the following steps:

[0041] (1) Synthesis of polyethylene glycol diacrylate

[0042] Weigh 50 grams of polyethylene glycol (number average molecular weight 4000), dissolve it in 700ml toluene, heat to reflux, remove the water content in the raw material with a water separator, cool to room temperature, under the protection of high-purity nitrogen, add 0.1 Mole of anhydrous triethylamine, 0.1 mole of acryloyl chloride was added dropwise, and stirred at 35°C for 24 hours. Remove the precipitate generated by the reaction by filtration, add 300 ml of diethyl ether to the filtrate and place it in a refrigerator at 4°C to precipitate a white precipitate, filter it, redissolve the precipitate in 100ml of benzene, add 200 ml of ether to the refrigerator at 4°C, precipitate a white precipitate, and repeat the filtration and dissolved twice, and the resulting white precipitate was dried in a vacuum oven at 35°C f...

Embodiment 2

[0048] (1) Synthesis of polyethylene glycol diacrylate

[0049] Weigh 50 grams of polyethylene glycol (number-average molecular weight 10000), dissolve it in 700ml toluene, heat to reflux, remove the water content in the raw material with a water separator, cool to room temperature, under the protection of high-purity nitrogen, add 0.04 Mole of anhydrous triethylamine, 0.04 mole of acryloyl chloride was added dropwise, and stirred at 35°C for 24 hours. Remove the triethylamine salt generated by the reaction by filtration, add 300 ml of ether to the filtrate and place it in a refrigerator at 4°C, a white precipitate precipitates, filter, redissolve the precipitate in 100ml of benzene, add 200ml of ether and place it in a refrigerator at 4°C, a white precipitate precipitates, Filtration and dissolution were repeated twice, and the resulting white precipitate was dried in a vacuum oven at 35°C for 24 hours.

[0050] (2) Synthesis of N-acryloylglucosamine: Dissolve 8.6g of glucos...

Embodiment 3

[0056] (1) Synthesis of polyethylene glycol diacrylate

[0057] Weigh 50 grams of polyethylene glycol (number-average molecular weight 10000), dissolve it in 700ml toluene, heat to reflux, remove the water content in the raw material with a water separator, cool to room temperature, under the protection of high-purity nitrogen, add 0.04 Mole of anhydrous triethylamine, 0.04 mole of acryloyl chloride was added dropwise, and stirred at 35°C for 24 hours. Remove the triethylamine salt generated by the reaction by filtration, add 300 ml of ether to the filtrate and place it in a refrigerator at 4°C, a white precipitate precipitates, filter, redissolve the precipitate in 100ml of benzene, add 200ml of ether and place it in a refrigerator at 4°C, a white precipitate precipitates, Filtration and dissolution were repeated twice, and the resulting white precipitate was dried in a vacuum oven at 35°C for 24 hours.

[0058] (2) Synthesis of N-acryloylglucosamine: Dissolve 8.6g of glucos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com