Boron nitride-containing silicone gel composition

A technology of boron nitride and silicon gel, which is applied in the direction of cosmetics, cosmetic preparations, skin care preparations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

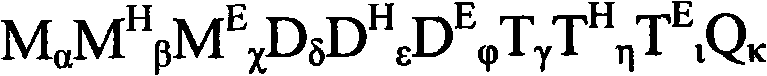

Image

Examples

Embodiment 1

[0218] A stable boron nitride powder-containing silicone gel composition (Silicone Gel A) was prepared according to the invention by combining the following ingredients (all from Momentive Performance Materials):

[0219] Element describe weight, g Wt.%

[0220] Velvesil 125 (in cyclopentasiloxane 48.72 69.60

[0221] Cross-linked C30-45 alkanes for silicone gels

[0222] Hexadecyl / octadecyl

[0223] Polydimethylsiloxane

[0224] (crosslinked

[0225] C30-45 alkyl

[0226] cetearyl

[0227] dimethicone))

[0228] Softouch TM Boron nitride powder 12.18 17.40

[0229] CC6097

[0230] Silsoft TM Silicone oil (octyl polymethyl 9.10 13.00

[0231] 034 silicone)

[0232] 70.00g 100.00%

[0233] Mix the silicone gel, boron nitride powder and silicone oil together at 600 rpm with an ...

Embodiment 2

[0235] Using the same ingredients as in Example 1, another stable boron nitride powder-containing silicone gel composition (silicone gel B) was prepared according to the present invention. The amounts of the various ingredients in the gel are as follows:

[0236] Element weight, g

[0237] Velvesil 125 69.6

[0238] silicone gel

[0239] Softouch TM 17.4

[0240] CC6097

[0241] Silsoft TM 13.0

[0242] 034

[0243] 100.0g

[0244] The gel was prepared by the following method: first Silsoft TM 034 added to Velvesil 125, then Softouch TM CC6097 while stirring at 100 g for 15 minutes at ambient temperature using an overhead mixer fitted with a 3-blade impeller.

Embodiment 3 and 4

[0246] Foundation compositions containing substantially the same amounts of the same ingredients (all amounts are in % by weight) were prepared by sequentially mixing the ingredients indicated below at 500 rpm and 80° C. for 20 minutes:

[0247] Element Example 3 Example 4

[0248] Velvesil 125 29.89 40.20

[0249] Polysilsesquioxane 10.62 10.62

[0250] Cyclopentasiloxane 36.63 36.63

[0251] Phenylpropyldimethyl-silyloxysilicic acid 2.71 2.71

[0252] Esters (Penylproplydimethyl-siloxy silicate)

[0253] C30-45 Alkyl Dimethicone 5.33 5.33

[0254] Silsoft TM 034 ----- 1.92

[0255] Silicone gel A (from Example 1) 14.82 -----

[0256] Softouch TM CC6097 ----- 2.58

[0257] 100.00 99.99

[0258]Each foundation composition was applied to Lenetta paper and drawn down to provide a 5 mil thick film. The film obtained with the foundation composition of Example 3 showed no visible agglomeration, whereas in the case of the film ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com