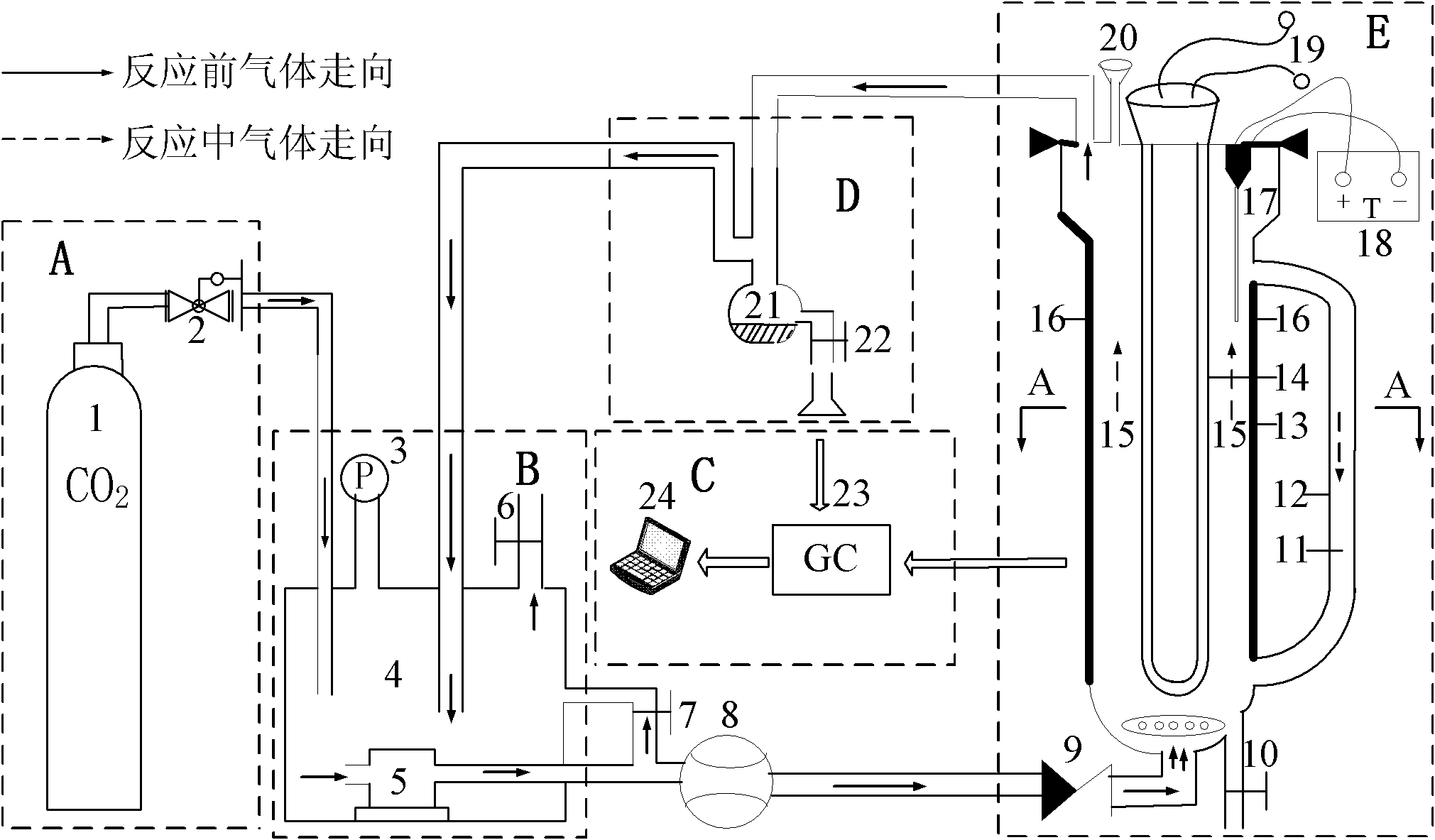

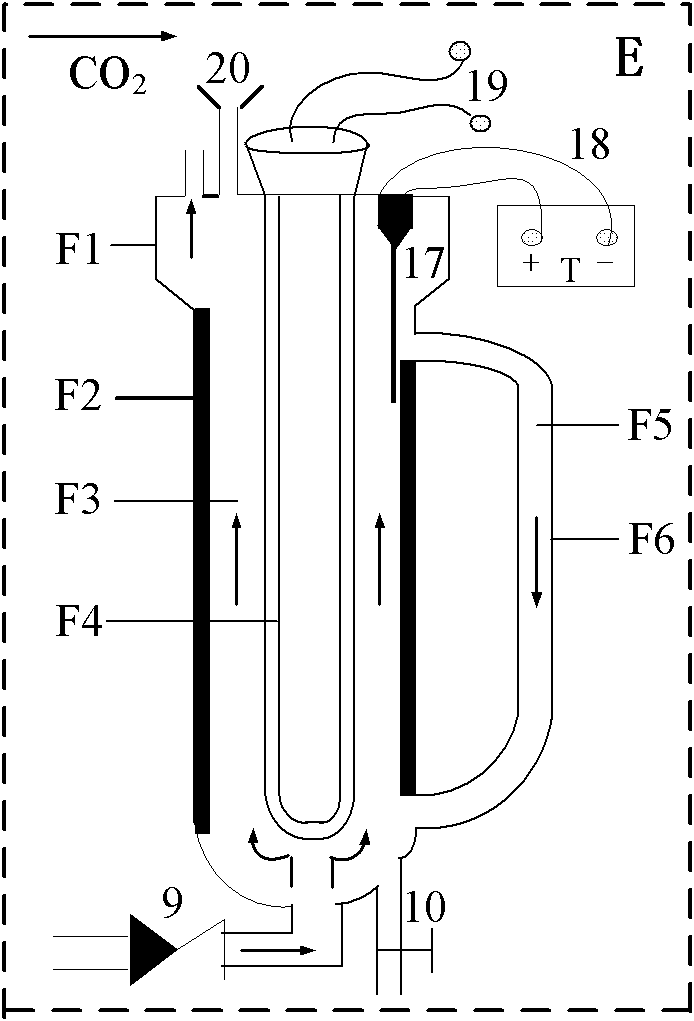

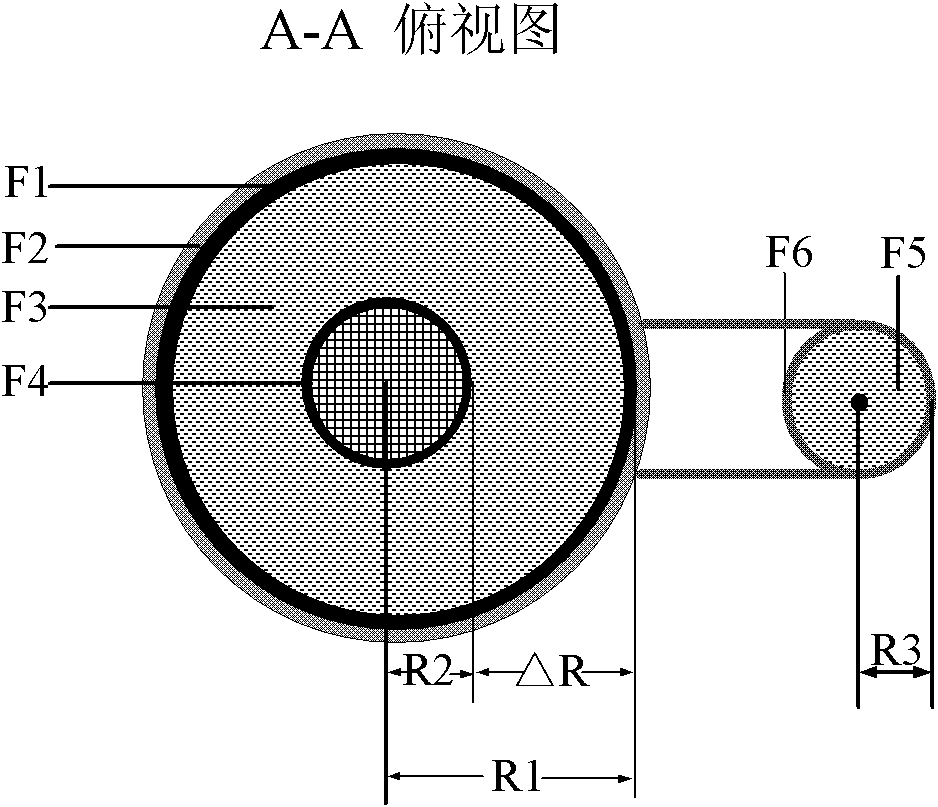

External circulation enclosed photocatalytic reduction CO2 reaction device

A technology of reaction device and external circulation, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physicochemical processes of energy application, etc. In order to achieve the effect of improving photocatalytic efficiency, good gas-liquid circulation rate and convenient product detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: Reaction system composition: the Na of preparation 0.10mol / L 2 SO 3 and 600 mL of 0.10 mol / L NaOH solution, put an appropriate amount of catalyst into the solution, and sonicate for 5 minutes. Then add the above-mentioned reaction solution into the outer circulation closed type photocatalytic reduction CO of the present invention 2 Reactor. CO 2 Pass it into the bottom of the reactor at a certain flow rate, turn on the ultraviolet lamp after 30 minutes, and turn off the gas source. Methanol content was analyzed by gas chromatography. Gas chromatography conditions: carrier gas N 2 60mL / min, H 2 The flow rate is 50mL / min, the air flow rate is 50mL / min, the column temperature is 90°C, the injection port is 150°C, and the detector is 180°C. Na added in the system 2 SO 3 It can provide electrons, absorb the holes generated by the illuminated semiconductor, and inhibit the recombination of electron-hole pairs, and adding NaOH can make the reaction syste...

Embodiment 2

[0031] Embodiment 2: Improved sol-gel method prepares Fe 3+ doped TiO 2 Powder photocatalyst and reduction of CO 2 Performance test: At room temperature, put butyl titanate, n-butanol, and glacial acetic acid in a molar ratio of 1:4:4 into an Erlenmeyer flask, stir for 0.5 hours, add ferric nitrate, and react for 8 hours. Obtain a light yellow transparent solution, place it for aging for 24 hours, dry it at 75°C, and then calcinate and grind it at 500°C to obtain granular Fe 3+ doped TiO 2 Catalyst, denoted as Fe-TiO 2 . Weigh 0.6g Fe-TiO 2 Mix with the reaction solution of Example 1 and add the outer circulation airtight photocatalytic reduction CO of the present invention 2 Reaction in the reaction device for 8h, CH 3 The OH yield was 60.13 μmol / g-cat (amount of methanol produced per gram of catalyst).

Embodiment 3

[0032] Embodiment 3: hydrothermal method prepares pure TiO 2 Nanotube Photocatalyst and CO Reduction 2 Performance test: put butyl titanate, n-butanol, and glacial acetic acid in a conical flask at a molar ratio of 1:4:4, and react for 8 hours to obtain a light yellow transparent solution, age for 24 hours, and dry at 75°C Calcined and ground at 500°C to obtain granular pure TiO 2 powder catalyst. Take the above TiO 2 Put 2g of the powder into 100mL10moL / L NaOH solution, ultrasonically oscillate for 5 minutes, put it into an autoclave, and react at a temperature of 110°C with a hydrothermal reaction time of 12h, 24h, and 36h. After the reaction, the solid-liquid mixture After centrifugation, the separated solid was calcined in a muffle furnace at 400°C for 2 hours to obtain three TiO 2 The nanotube samples are respectively denoted as TNTs-12, TNTs-24, and TNTs-36. Weigh 0.6g of the above-mentioned nanotube catalyst and mix it with the reaction solution of Example 1 and ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com