Glutinous rice starch/acrylic ester interpolymer and composite and application thereof

An acrylate and copolymer technology, which is applied in the field of sticky rice starch/acrylate copolymer and its composition, can solve the problems of not being popularized and applied, the rebirth of cooked sticky rice cakes, and the short sticking time, etc. High temperature on energy waste, high drug loading, overcoming the effect of active ingredient damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0028] Add 6g of glutinous rice starch and 60g of distilled water into a four-neck flask, heat to 80°C for gelatinization for 30 minutes under nitrogen protection and stirring; cool down to 60°C, add a few drops of sodium hydroxide solution to adjust pH=9~10, weigh Take 0.1g of potassium persulfate, dissolve it with a small amount of water, slowly drop it into the reactor, keep the temperature constant and stir for 10-30 minutes; then add 1g of acrylic acid and 5g of butyl methacrylate, and react at 65-70°C for 3 hours Adjusting the pH to be neutral, removing part of the water under reduced pressure, then discharging, drying and grinding to obtain the sticky rice starch / acrylic acid ester copolymer AS1.

example 2

[0030]Add 6g of glutinous rice starch and 40g of distilled water into a four-necked flask, heat to 90°C for gelatinization for 20 minutes under nitrogen protection and stirring; cool down to 60°C, add a few drops of saturated aqueous sodium bicarbonate solution to adjust pH = 9, weigh Potassium persulfate 0.1g, dissolved with a small amount of water, slowly added dropwise to the reactor, kept the temperature constant and stirred for 10 minutes; then added 1g of methacrylic acid and 2g of butyl acrylate, reacted at 65-70°C for 12 hours; adjusted the pH Neutral, depressurize to remove part of the water, discharge, dry and grind to obtain sticky rice starch / acrylate copolymer AS2.

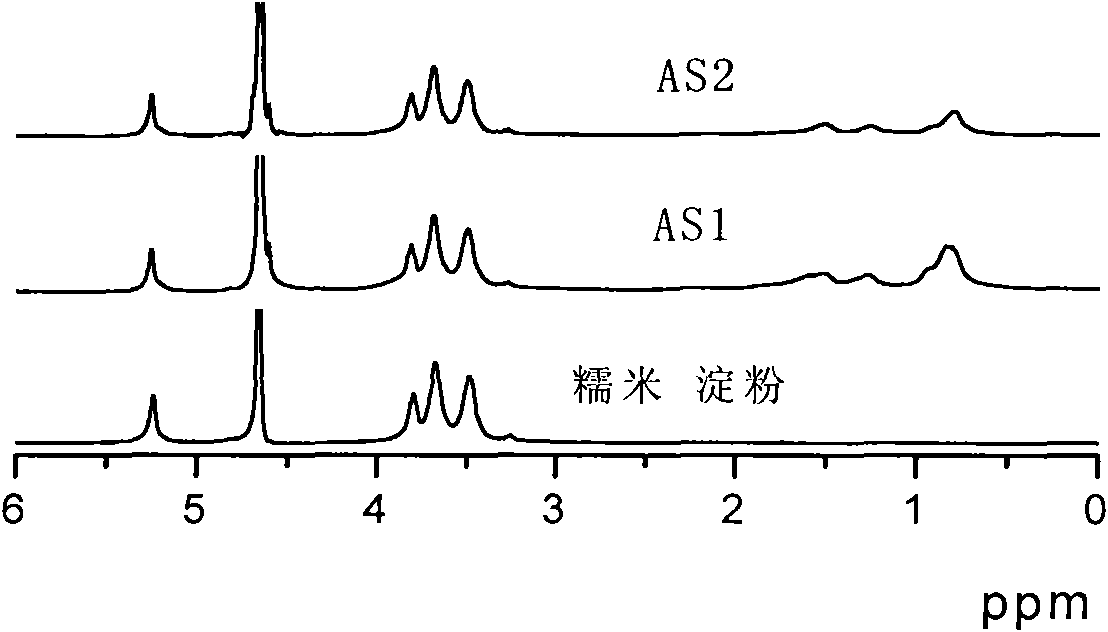

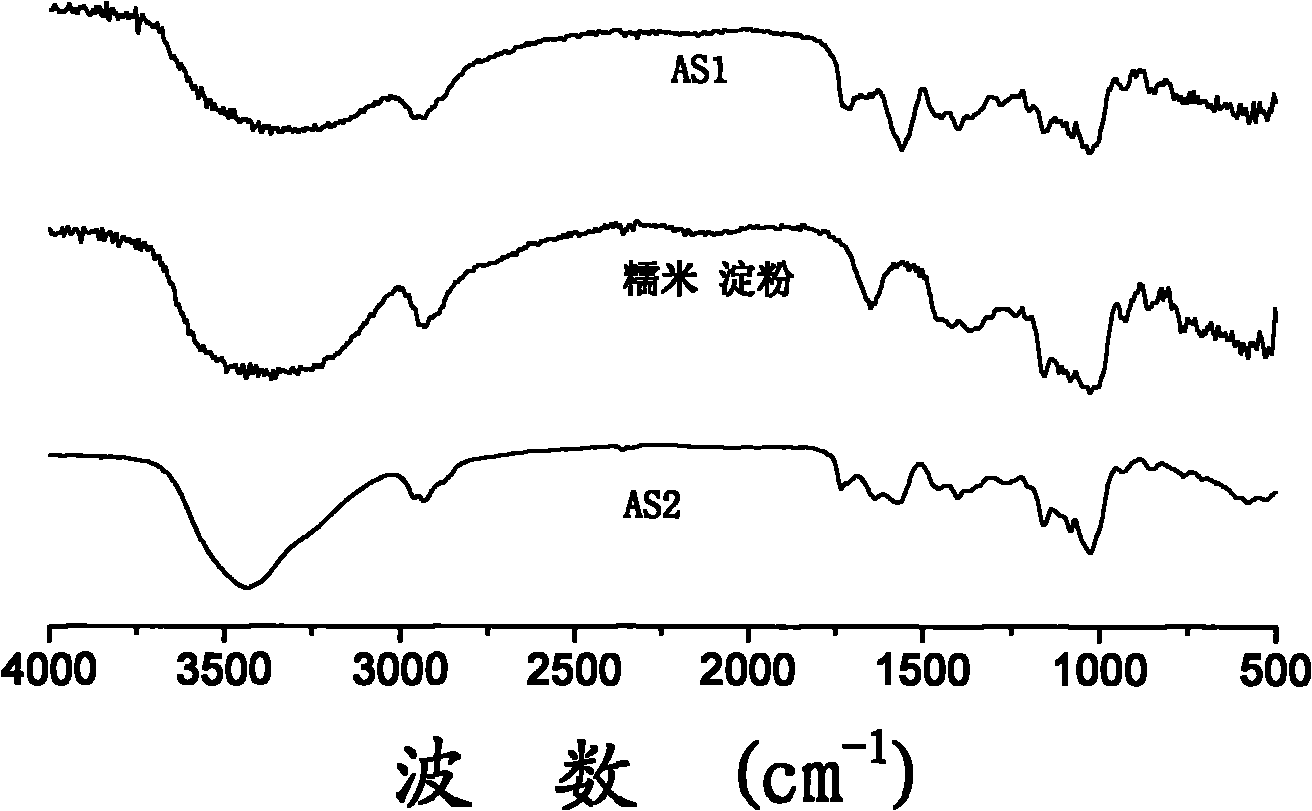

[0031] figure 1 It is the nuclear magnetic resonance spectrum of the sticky rice starch / acrylate copolymer (AS1 and AS2) prepared by glutinous rice starch, embodiment 1 and 2. Compared with the NMR spectra of glutinous rice starch, the characteristic peaks of methyl and methylene groups on methacryli...

example 3

[0034] Add 1g of sticky cornstarch and 100g of distilled water to a four-neck flask, heat to 90-100°C for gelatinization for 20 minutes under nitrogen protection and stirring; cool down to 60°C, add a few drops of 10% sodium hydroxide solution to adjust the pH 9 to 10, weigh 0.2g of potassium persulfate, dissolve it with a small amount of water, slowly drop it into the reactor, keep the temperature constant and stir for 10 minutes; then add 8g of methacrylic acid, 6g of acrylic acid, 4g of isopropyl acrylate and 2g of Isooctyl acrylate is reacted at 65-70°C for 16 hours; NaOH solution is added to adjust the pH to be neutral, part of the water is removed under reduced pressure, and then the material is discharged, dried and ground to obtain the sticky rice starch / acrylate copolymer AS3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com