Processing method of electroplating wastewater containing cyanogens and chrome

A treatment method and a chromium electroplating technology are applied in the field of treatment of cyanide-containing chromium-containing electroplating wastewater, which can solve the problems of unpublished concentrated water treatment methods, unsuitability for treatment, and high energy consumption, achieve significant energy-saving effects, and simplify the concentrated water treatment process. , the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

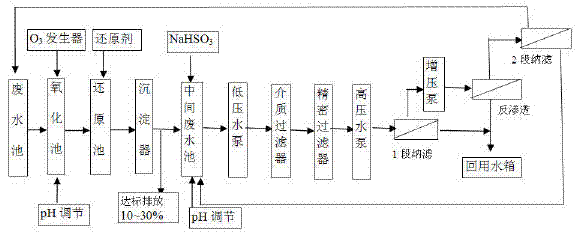

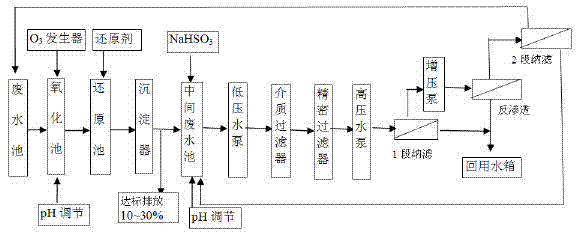

[0026] A mixed electroplating wastewater containing cyanide and chromium, the pH value is 7.5, the total cyanide content is 21.8mg / L, the hexavalent chromium content is 27.5mg / L, and the total heavy metal ion content such as copper and zinc is less than 100mg / L. use as figure 1 The method shown:

[0027] (1) Adjust the pH value of electroplating wastewater to 8.5 with 20% NaOH solution;

[0028] (2) Start O 3 generator, press O 3 :CN - The mass ratio is 4:1 into O 3 , stir, and control the oxidation time to 45 minutes (min) before entering the reduction pool;

[0029] (3) According to hydrazine hydrate (N 2 h 2 ·H 2 O) The mass ratio of hexavalent chromium to hexavalent chromium is 0.75:1. Add the reducing agent hydrazine hydrate into the reduction pool, stir, and the waste water is sent to the precipitator for solid-liquid separation after the reduction time in the reduction pool is 30 minutes;

[0030] (4) After precipitation, the clear liquid reaches the comprehens...

Embodiment 2

[0039] A mixed electroplating wastewater containing cyanide and chromium, the pH value is 8.8, the total cyanide content is 31.5 mg / L, the hexavalent chromium content is 37.8 mg / L, and the total heavy metal ion content such as copper and zinc is 100 ~ 200 mg / L L. Since the pH value of electroplating wastewater is 8.8, there is no need to adjust the pH value. The specific treatment steps are as follows:

[0040] (1) Start O 3 generator, press O 3 :CN - (mass ratio) 5:1 into O 3 , stir, and control the oxidation time to 60 minutes before entering the reduction pool;

[0041] (3) According to hydrazine hydrate (N 2 h 2 ·H 2 O) The mass ratio of hexavalent chromium to hexavalent chromium is 1:1. Add the reducing agent hydrazine hydrate into the reduction pool, stir, and the waste water is sent to the precipitator for solid-liquid separation after the reduction time in the reduction pool is 60 minutes;

[0042] (4) After precipitation, the clear liquid reaches the comprehen...

Embodiment 3

[0051] A kind of mixed electroplating wastewater containing cyanide and chromium, the pH value is 9.2, wherein the total cyanide content is 51.3 mg / L, the hexavalent chromium content is 62.8 mg / L, and the total heavy metal ion content such as total copper, total zinc, and total chromium is Greater than 200mg / L. Because the pH value of electroplating wastewater is 9.2, there is no need to adjust the pH value. The specific treatment steps are as follows:

[0052] (1) Start O 3 generator, press O 3 :CN - (mass ratio) 6:1 into O 3 , stir, and control the oxidation time to 60 minutes before entering the reduction pool;

[0053] (3) According to hydrazine hydrate (N 2 h 2 ·H 2 O) The mass ratio of hexavalent chromium to hexavalent chromium is 1:1. Add the reducing agent hydrazine hydrate into the reduction pool, stir, and the waste water is sent to the precipitator for solid-liquid separation after the reduction time in the reduction pool is 60 minutes;

[0054] (4) After se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com