Preparation method of cagelike silsesquioxane-contained polymethyl methacrylate hybrid material

The technology of siloxane polymethyl methacrylate and methyl methacrylate is applied in the field of polymethyl methacrylate hybrid materials, and can solve the problem that the preparation process of polymethyl methacrylate/POSS hybrid materials is complicated, ATRP initiator POSS has long synthetic route and difficult to control reaction process, etc., to achieve the effect of short reaction route, simple synthesis conditions and simplified preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

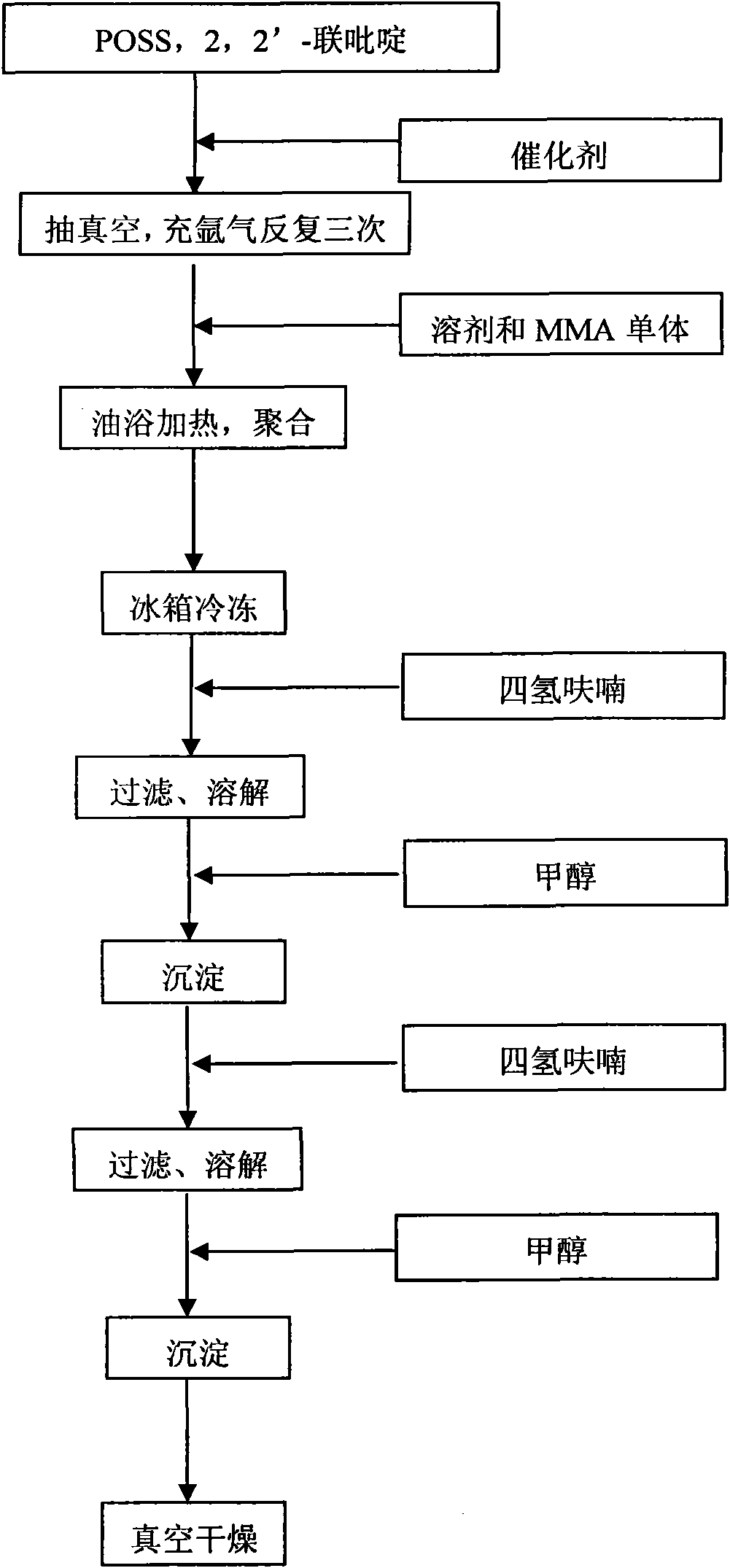

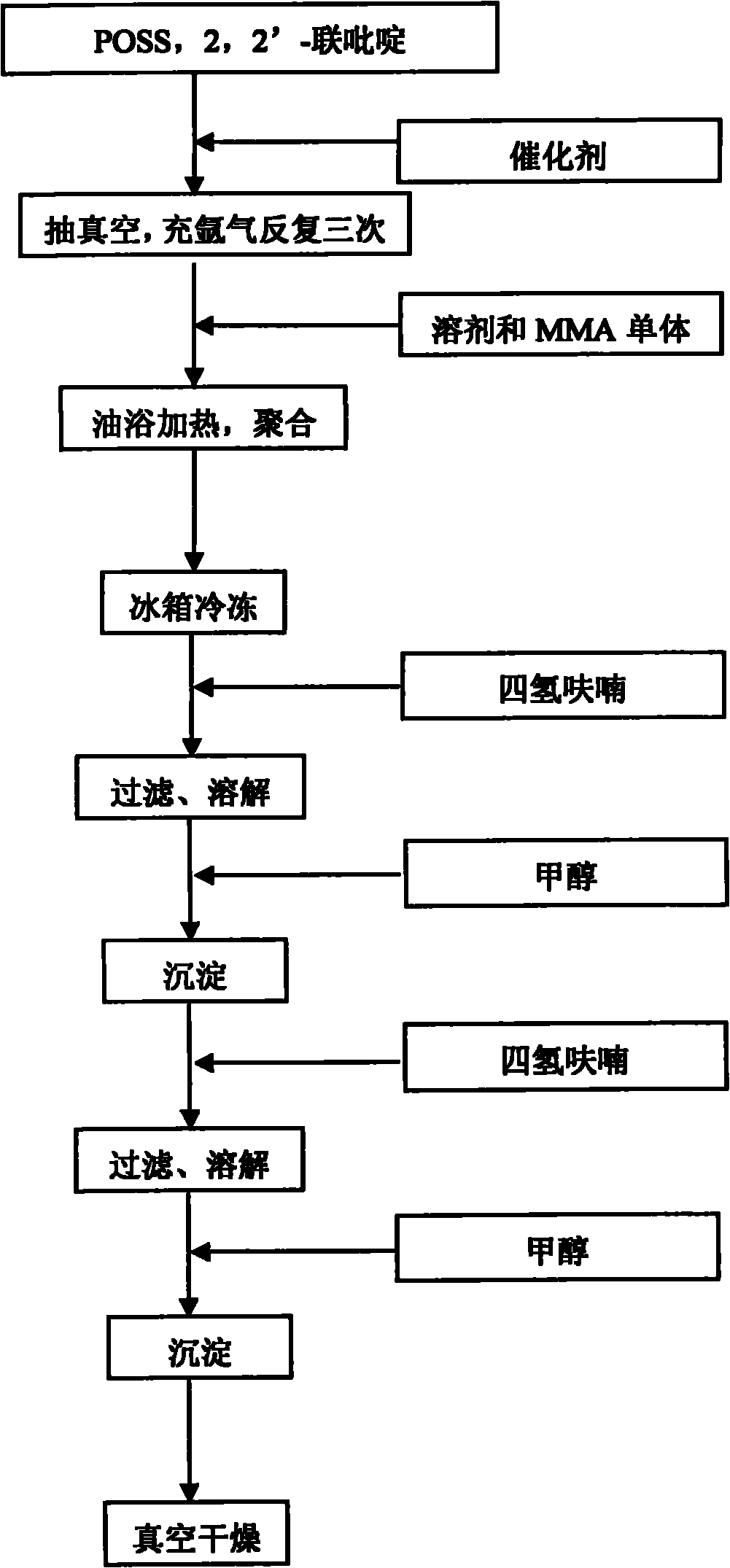

[0016] The preparation method of polymethyl methacrylate hybrid material containing clathrate silsesquioxane of the present invention is realized by atom transfer radical polymerization, comprising the following steps:

[0017] The first step: Add initiator, catalyst and complexing agent in the dry reaction bottle, vacuumize, and fill with argon to react, wherein the initiator is octa(γ-chloropropyl)silsesquioxane, and the catalyst is chlorine Cuprous chloride or cuprous bromide, the complexing agent is 2,2'-bipyridine; the mass ratio of initiator to catalyst is 1.85:1~2.0:1, and the mass ratio of complexing agent to catalyst is 3.70:1~4.0 : 1. The ratio of the amount of methyl methacrylate monomer to the amount of the initiator is 750:1-900:1.

[0018] Step 2: Add solvent and methyl methacrylate monomer MMA, stir evenly, after heating the reaction, stop the reaction by freezing, such as about minus 18 degrees; the heating temperature is 80-100°C, and the reaction time is 5-2...

Embodiment 1

[0021] In a dry reaction flask, under the protection of argon, add 0.240 g of complexing agent 2,2′-bipyridine, 0.125 g of initiator octa(γ-chloropropyl) silsesquioxane, catalyst cuprous chloride 0.064g, vacuumize, fill with argon, repeat three times; inject 10mL toluene solvent and 10mL methyl methacrylate monomer, and react at 90°C for 15 hours. After the reaction, take out the reaction bottle and place it in the refrigerator to freeze to terminate the reaction. 5 mL of tetrahydrofuran was added to dissolve the polymer, filtered, and the filtrate was added to a large amount of methanol for precipitation. The precipitate was dissolved in tetrahydrofuran again, reprecipitated, and finally vacuum-dried to obtain the product with a yield of 17%.

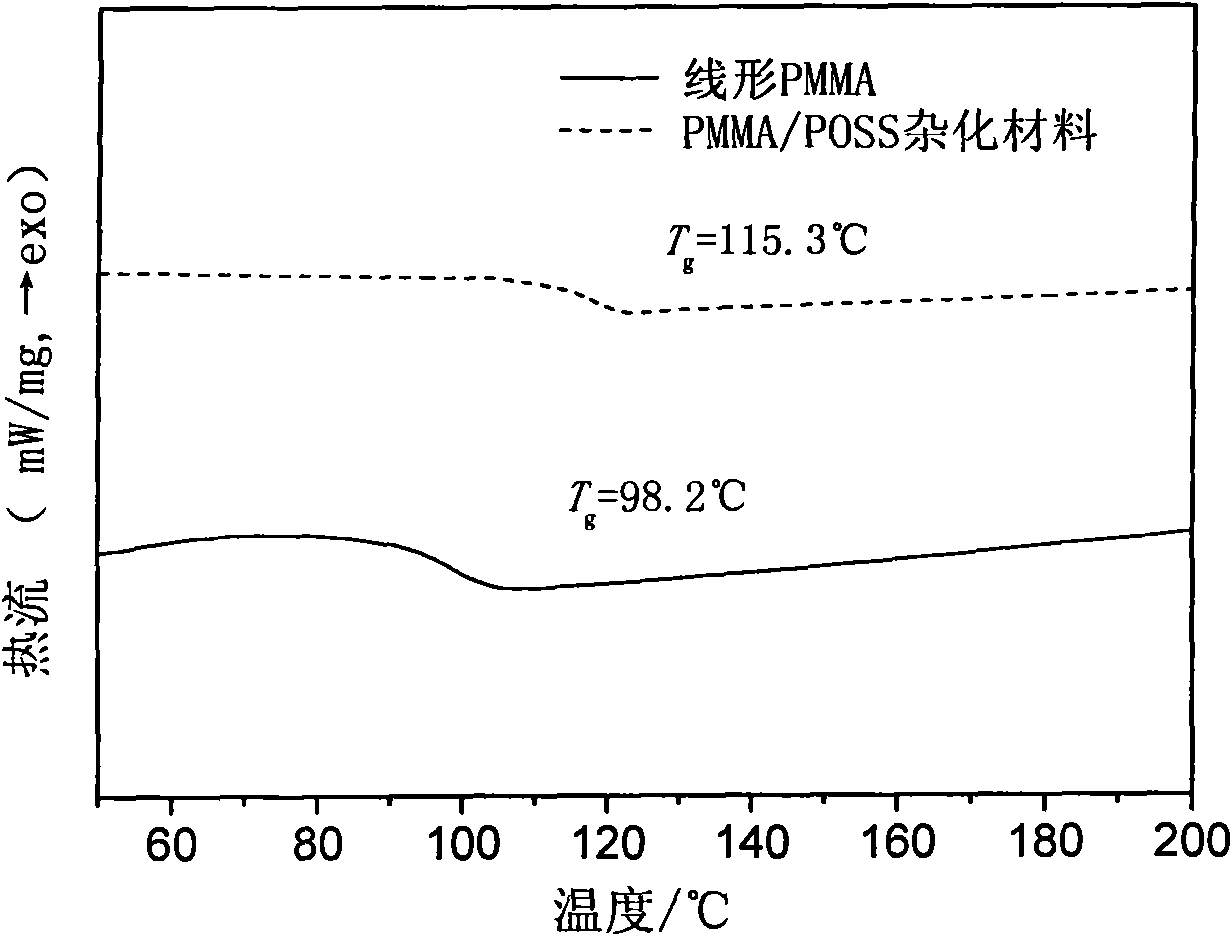

[0022] In this embodiment, the polymethyl methacrylate hybrid material can be obtained by using toluene as a solvent. The number average molecular weight of the hybrid material is 102572g / mol, the molecular weight distribution index (P...

Embodiment 2

[0024] In a dry reaction flask, under the protection of argon, add 0.240 g of complexing agent 2,2′-bipyridine, 0.125 g of initiator octa(γ-chloropropyl) silsesquioxane, catalyst cuprous chloride 0.064g, vacuumize, fill with argon, repeat three times; inject 10mL isopropanol solvent and 10mL methyl methacrylate monomer, react at 80°C for 15 hours, after the reaction, take out the reaction bottle, put it in the refrigerator to stop To react, add 5 mL of tetrahydrofuran to dissolve the polymer, filter, add the filtrate to a large amount of methanol for precipitation, and dissolve the precipitate with tetrahydrofuran again, reprecipitate, and finally vacuum dry to obtain the product with a yield of 21%.

[0025] In this embodiment, the polymethyl methacrylate hybrid material can also be obtained by using isopropanol as a solvent. The number average molecular weight of the hybrid material is 28308g / mol, the molecular weight distribution index (PDI) is 1.25, and the glass transitio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com