Modified polyvinylidene fluoride material as well as preparation method and application thereof in hollow fiber membrane material

A technology of polyvinylidene fluoride and vinylidene fluoride, which is applied in the field of modified polyvinylidene fluoride materials, preparation and application in hollow fiber membrane materials, can solve the problem of decreased hydrophilicity, unsatisfactory modification effect, and improved The effect of hydrophilicity is limited and not durable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

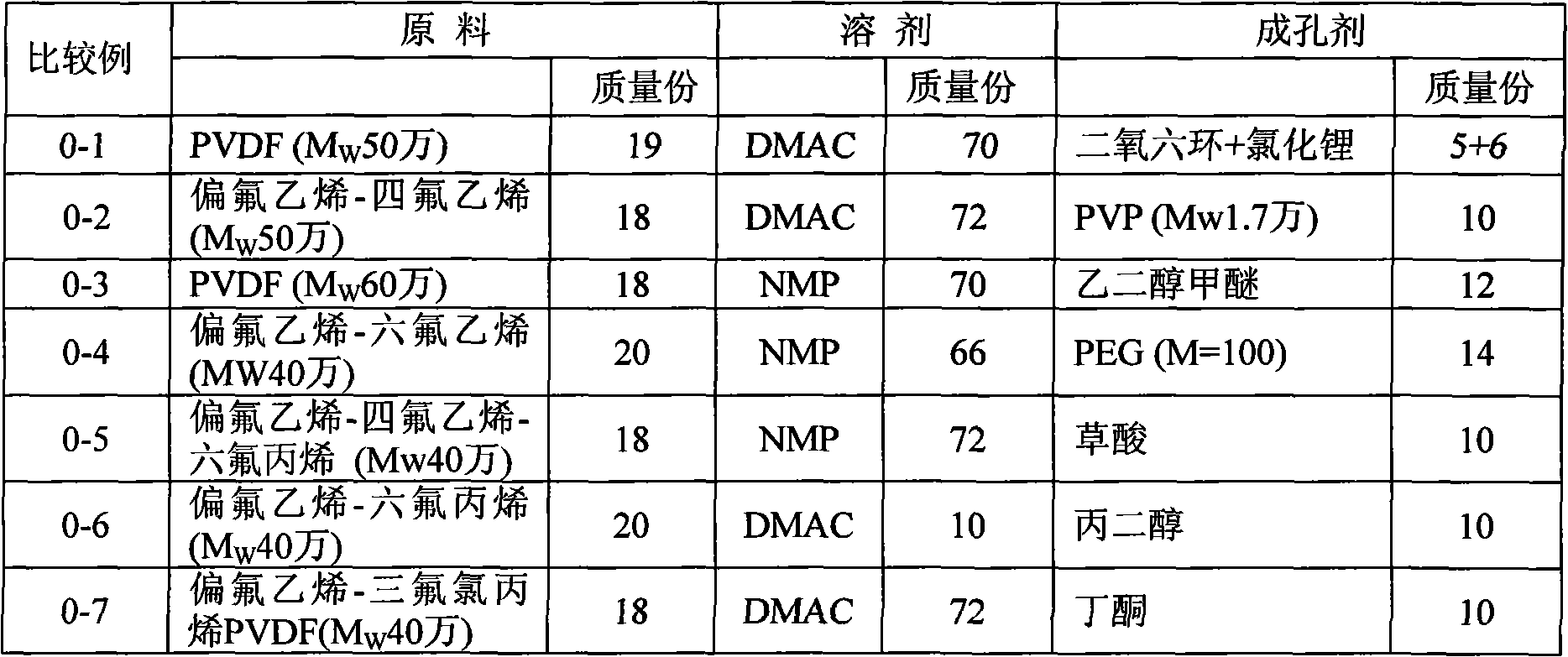

[0022] 1. Comparative example: prepare hollow fiber membrane according to the current traditional method

[0023] 1. Stir PVDF and solvent at a constant temperature of 90°C for 10 hours at a high speed, add a pore-forming agent and continue stirring for 12 hours, then statically defoam to obtain a casting solution. Membranes are formed after spinning, shearing and post-treatment in a conventional manner, and the compositions of coagulation liquid and core liquid are changed to obtain internal (external) pressure hollow fiber membranes. The inner diameter of the membrane filament is 0.6-0.8 mm, and the wall thickness is 0.2-0.4 mm.

[0024] The raw materials and consumption etc. of each comparative example are shown in Table 1.

[0025] Raw materials and consumption of each comparative example of table 1

[0026]

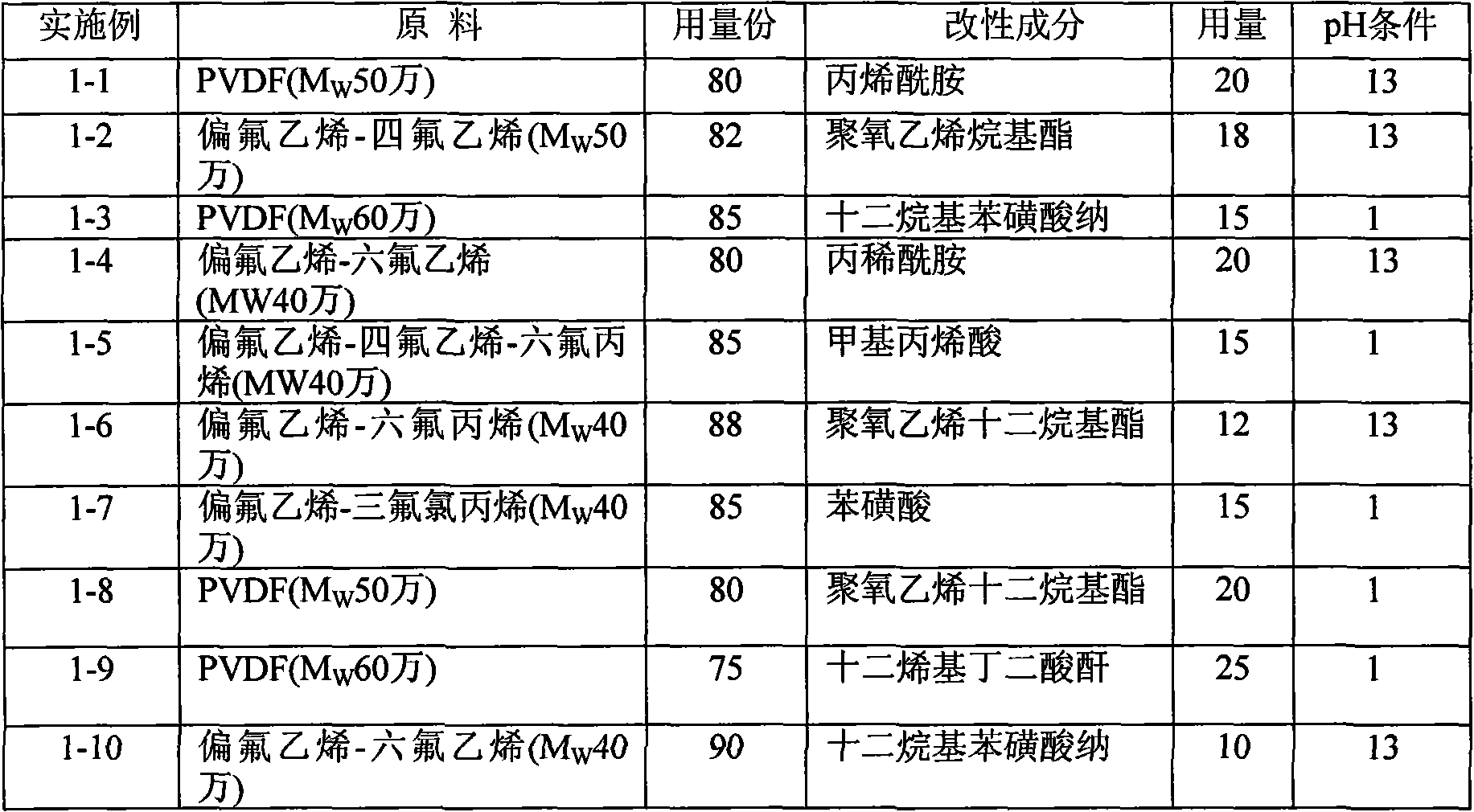

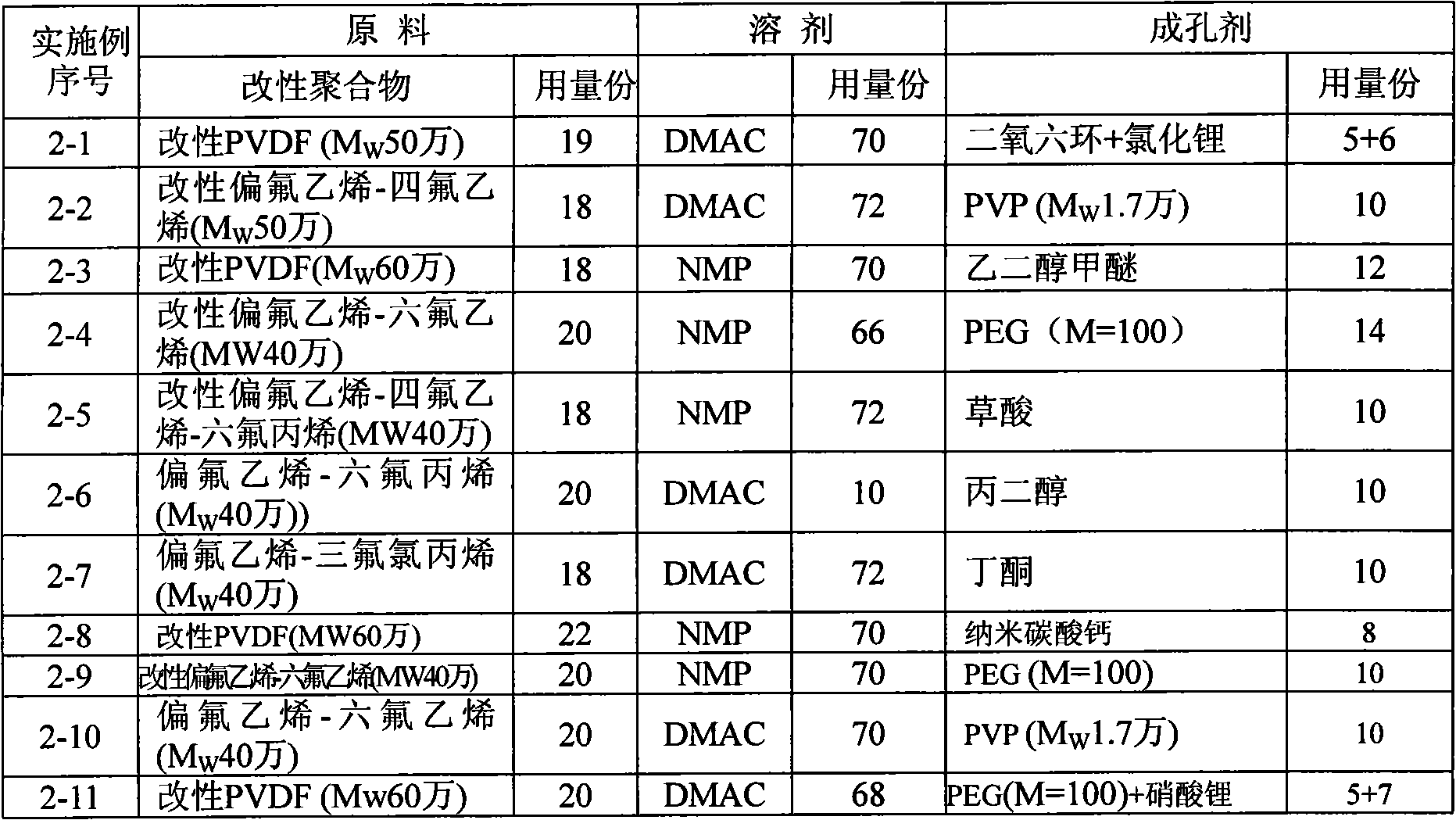

[0027] Two, the modified PVDF material embodiment of the present invention

[0028] Stir the PVDF or vinylidene fluoride copolymers corresponding to the compar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com