Preparation method of three-dimensional porous tin-copper alloy cathode materials for lithium ion battery

A lithium-ion battery, three-dimensional porous technology, applied in the field of electrochemistry, can solve the problem of insufficient stability of the porous structure, and achieve the effect of facilitating large-scale production, improving cycle performance, and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Ultrasonic cleaning the copper foam with acetone and dilute hydrochloric acid respectively to remove oil and scale.

[0025] 2. Immerse the pre-treated foamed copper in the electroless tin plating solution, and deposit a layer of off-white tin plating on the foamed copper under room temperature ultrasonic conditions.

[0026] 3. Put the tin-coated copper foam in a vacuum oven at 150°C for 2 hours. Under high temperature conditions, the tin-copper alloy phase is formed due to the atomic diffusion between tin and copper, thereby preparing a three-dimensional porous tin-copper alloy anode.

[0027] 4. Before being assembled into a battery, the three-dimensional porous tin-copper alloy negative electrode is pressed into a thin sheet under a pressure of 3Mpa, and then battery assembly and performance testing are performed.

[0028] Result Characterization:

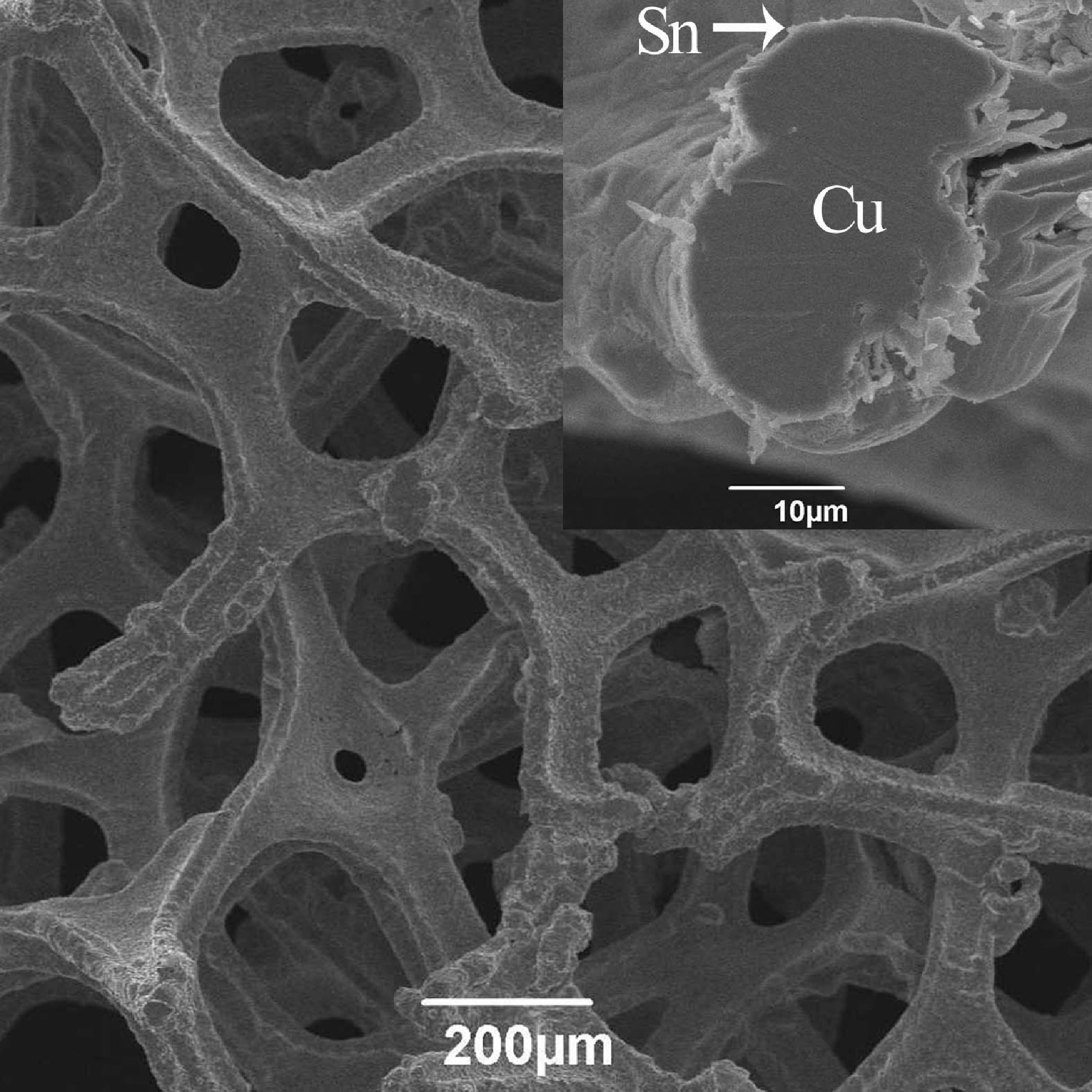

[0029] a. by attached figure 1 It can be seen that the copper foam is a three-dimensional porous structure with ...

Embodiment 2

[0033] 1. Ultrasonic cleaning the copper foam with acetone and dilute hydrochloric acid respectively to remove oil and scale.

[0034] 2. Immerse the pretreated copper foam in the electroless tin plating solution, and keep it ultrasonic for 3 minutes at room temperature, and deposit a layer of off-white tin plating on the foam copper.

[0035]3. Press the non-heat-treated tin-coated copper foam into a thin sheet under a pressure of 3Mpa, and then perform battery assembly and performance testing.

[0036] Result Characterization:

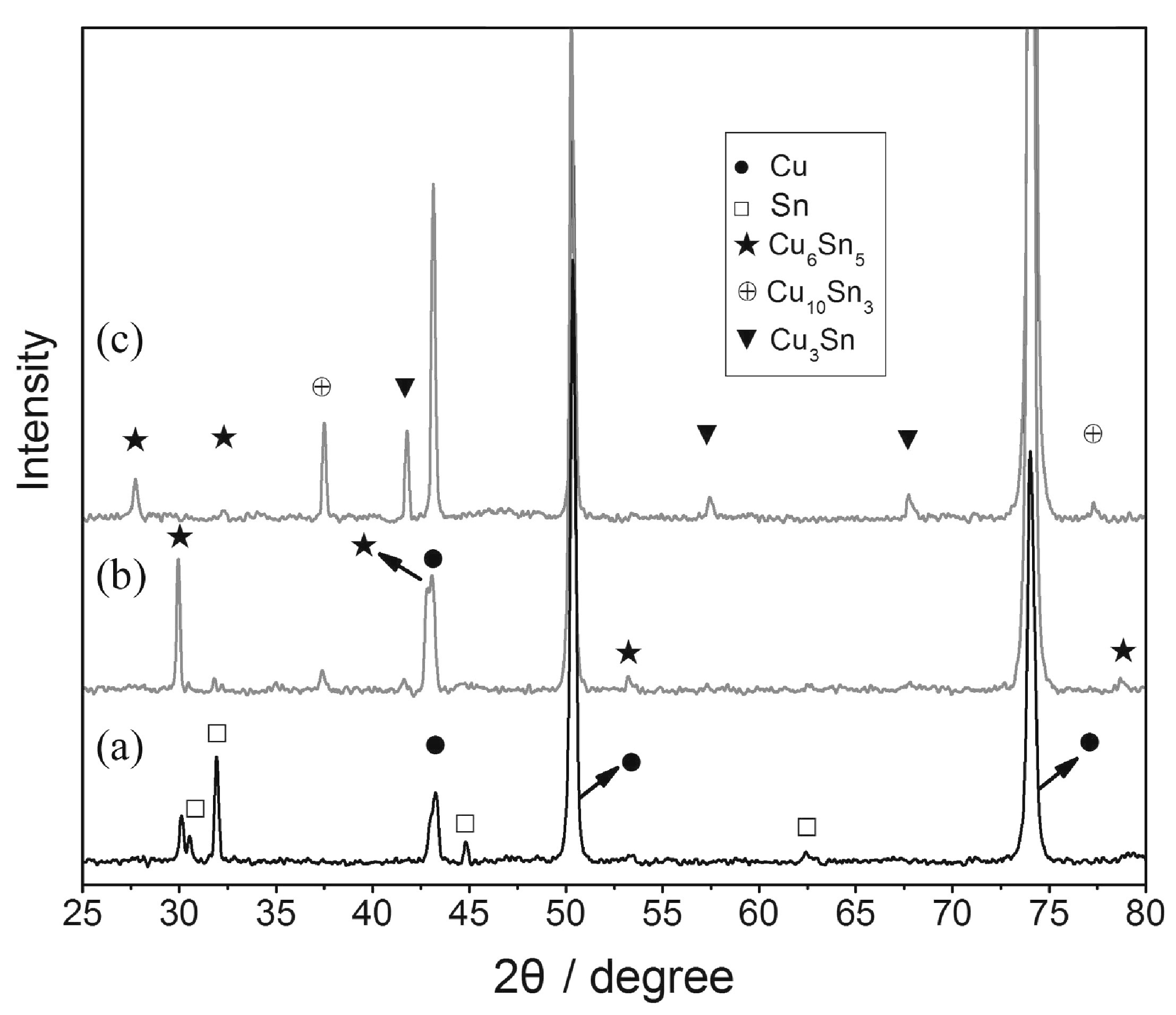

[0037] a. by attached figure 2 a It can be seen that for the non-heat-treated tin-coated copper foam, in addition to the diffraction peaks of copper as the substrate, there are also diffraction peaks of Sn and Cu 6 sn 5 Alloy phase diffraction peaks, indicating that the electrode is three-dimensional porous Sn-Cu 6 sn 5 composite electrode.

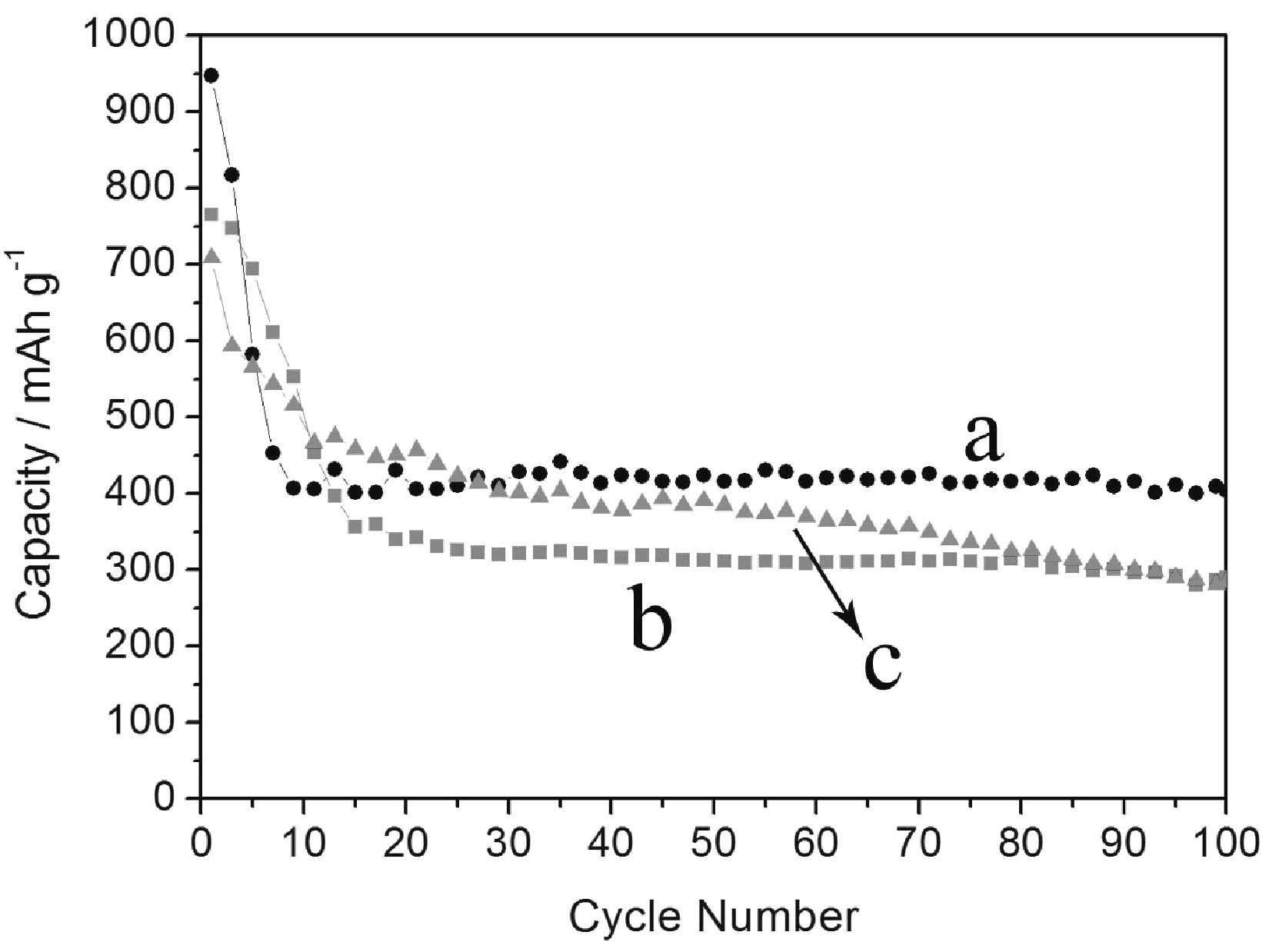

[0038] b. By attached image 3 b It can be seen that the three-dimensional porous Sn-Cu obtained unde...

Embodiment 3

[0040] 1. Ultrasonic cleaning the copper foam with acetone and dilute hydrochloric acid respectively to remove oil and scale.

[0041] 2. Immerse the pretreated copper foam in the electroless tin plating solution, and keep it ultrasonic for 3 minutes at room temperature, and deposit a layer of off-white tin plating on the foam copper.

[0042] 3. Place the tin-coated copper foam in a vacuum oven at 200°C for 24 hours. Under high temperature conditions, a tin-copper alloy phase is formed due to atomic diffusion between tin and copper. Thus, a three-dimensional porous tin-copper alloy anode was prepared.

[0043] 4. The three-dimensional porous tin-copper alloy negative electrode was pressed into a thin sheet under a pressure of 3Mpa for battery assembly and performance testing.

[0044] Result Characterization:

[0045] a. by attached figure 2 c It can be seen that after heat treatment at 200°C for 24 hours, except for the diffraction peak of copper as the substrate, it is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com