Laser machining device

A technology of laser processing and laser beam, which is applied in the direction of fine working devices, auxiliary devices, metal processing, etc., can solve problems such as the complexity of laser optical systems, and achieve the effect of reducing the driving mechanism, small driving force, and reducing the installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

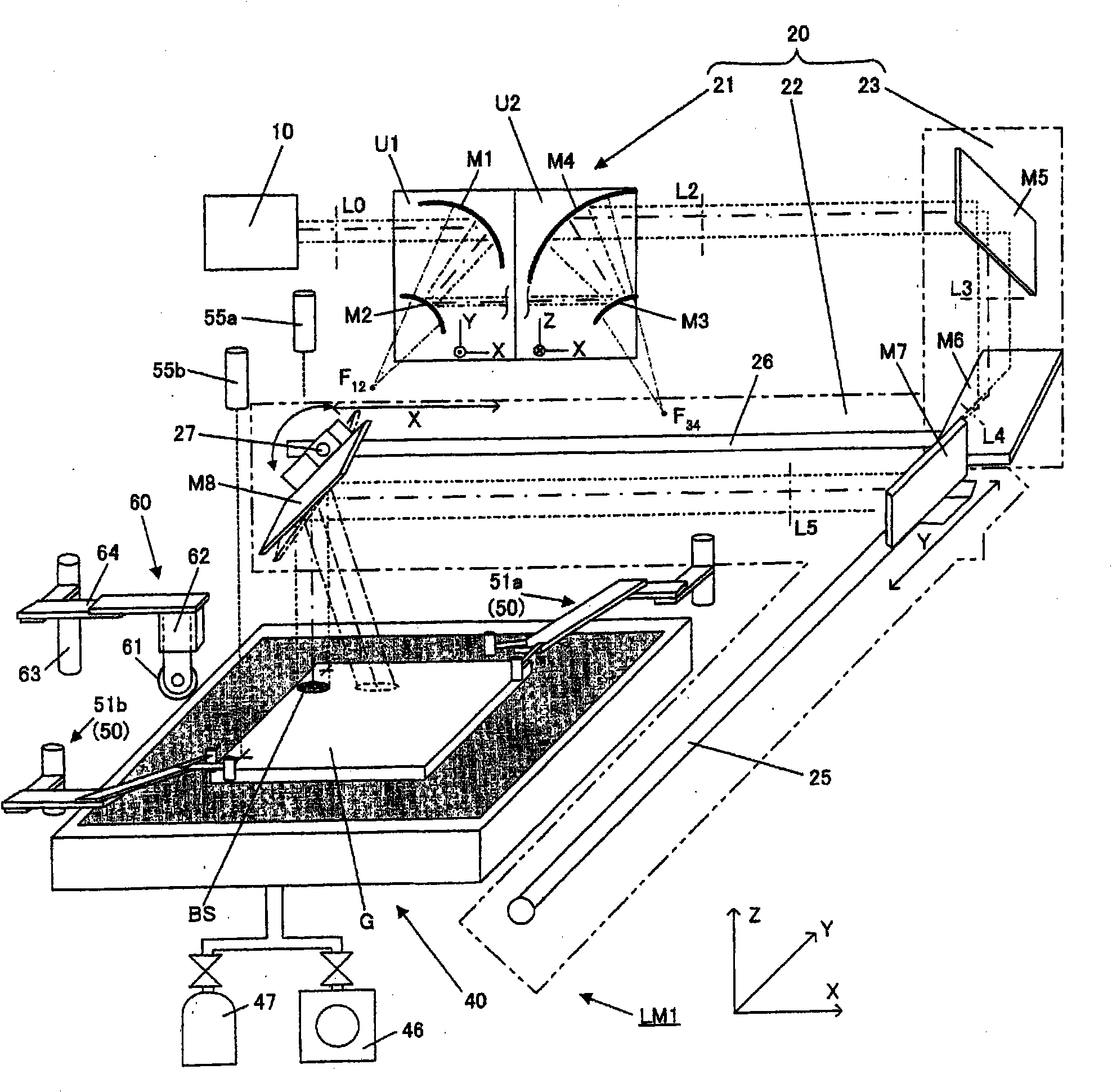

[0118] figure 1 It is the whole structure diagram of the laser processing apparatus LM1 which is one Embodiment of this invention. The laser processing device LM1 is mainly composed of a laser light source 10 , a laser scanning optical system 20 , a table 40 , a substrate guide mechanism 50 , and a trigger mechanism 60 .

[0119] (laser light source)

[0120] The laser light source 10 adopts CO 2 laser. Can also replace CO 2 Lasers use CO lasers and excimer lasers. A laser beam (original beam L0 ) having a circular cross-sectional shape is emitted from the laser light source 10 . In addition, in the case of laser ablation processing, a laser light source having a wavelength and an energy density capable of melting and evaporating the substrate material is used.

[0121] (laser scanning optical system)

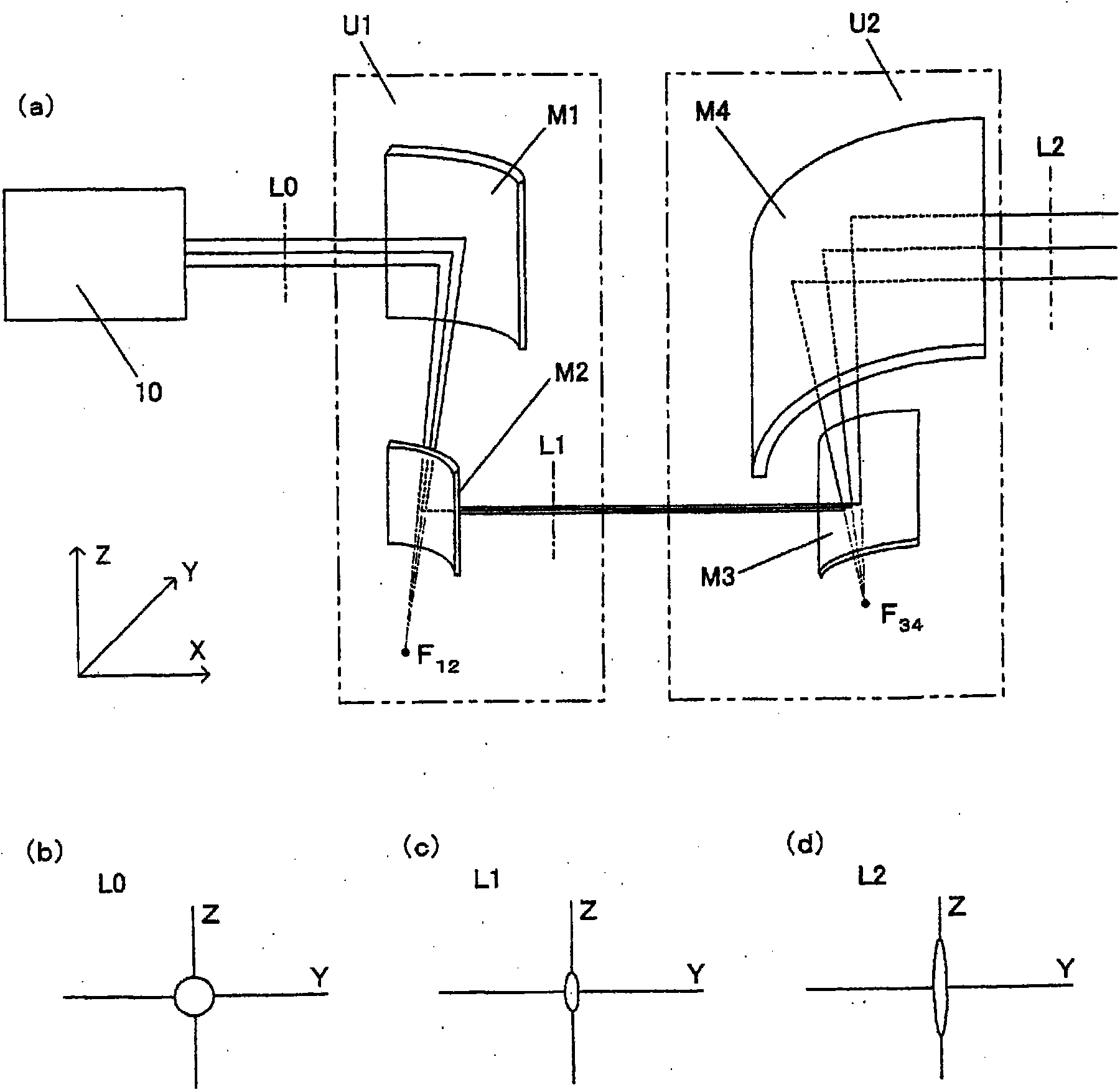

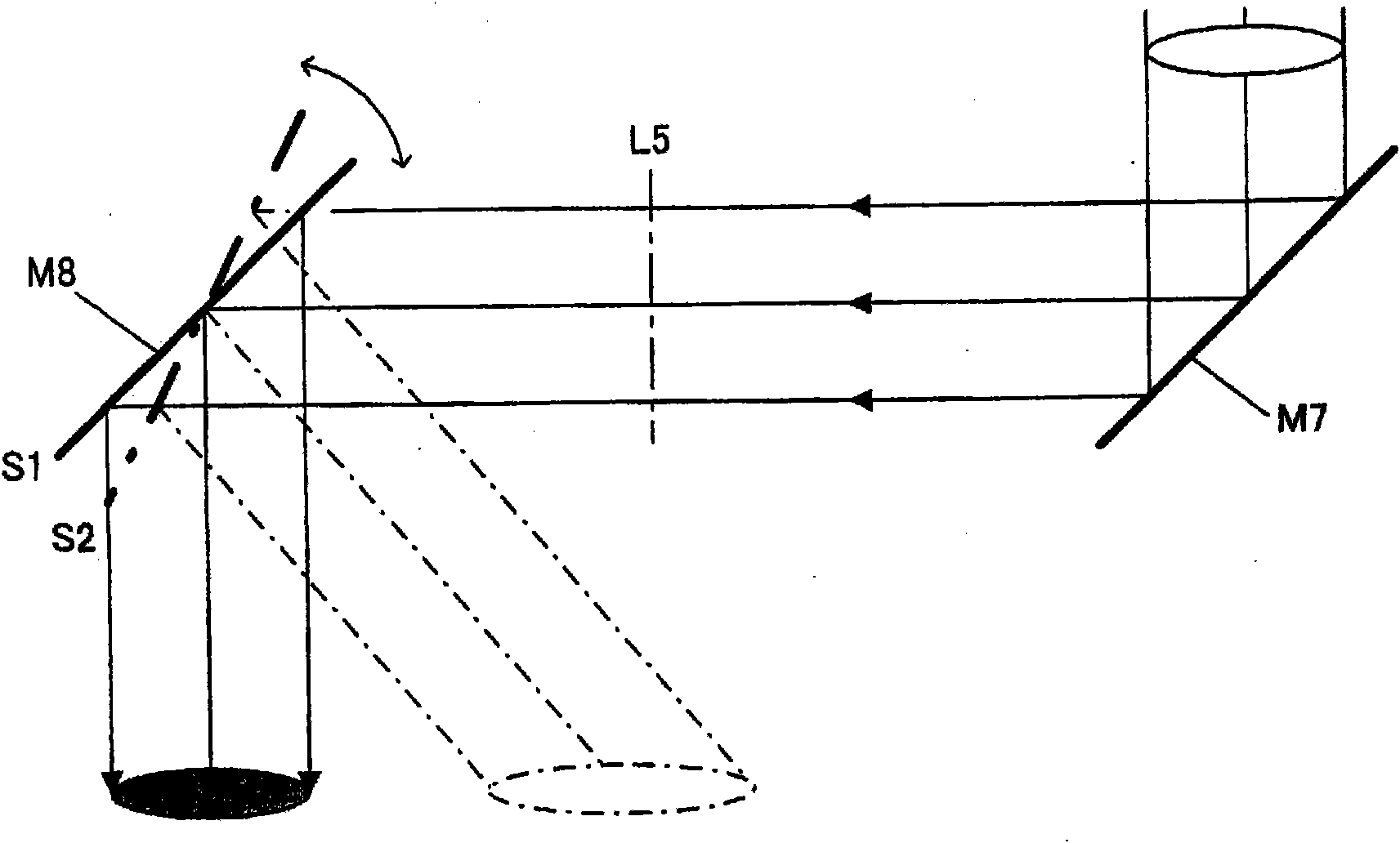

[0122] The laser scanning optical system 20 is roughly composed of the following parts: a beam shaping part 21 that adjusts the cross-sectional shape of the laser beam;...

no. 2 approach

[0170] Next, a second embodiment of the present invention will be described. Figure 7 It is an overall configuration diagram of a laser processing apparatus LM2 as a second embodiment of the present invention, Figure 8 It is a block diagram which shows the control system of laser processing apparatus LM2. For and use Figure 1 to Figure 6The parts common to the structure of the description are assigned the same symbols, and the description of this part is omitted. The laser processing device LM2 is modified from the laser processing device LM1 in that a variable focus parabolic mirror is movably attached, and a control unit 80a is configured by adding a parabolic mirror drive unit 88 for driving the parabolic mirror.

[0171] Figure 9 It is a figure which shows the structural example of the beam shaper 21a of the laser processing apparatus LM2.

[0172] The beam shaper 21 a is composed of four optical elements of a first parabolic mirror (concave surface) M1 , a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com