Preparation method of nanometer cordierite-based ceramic dielectric material used for high-frequency chip inductor

A ceramic medium and cordierite technology, which is applied in the field of inorganic non-metallic materials and industrial functional ceramics, can solve the problems of irregular and uniform powder particle size distribution, unfavorable low-temperature co-firing, high degree of powder agglomeration, etc., and achieve regular shape Uniformity, high powder surface activity, high surface activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A preparation method of nano cordierite-based ceramic dielectric material for high-frequency chip inductors includes the following steps:

[0021] 1. Preparation of magnesium aluminum silica sol: according to cordierite (Mg 2 Al 4 Si 5 O 18 ), the stoichiometric ratio of aluminum nitrate nonahydrate (Al(NO 3 ) 3 ·9H 2 O), magnesium nitrate hexahydrate (Mg(NO 3 ) 2 ·6H 2 O) Add to water, place on a magnetic stirrer and stir vigorously. Maintain the temperature at 50°C. Stir for 30 minutes to completely dissolve. Add TEOS and continue stirring to obtain a colorless transparent liquid; then dissolve in 20% Bismuth trioxide (Bi 2 O 3 ) Is added to the above colorless and transparent liquid, adjusted the PH value to 1, and stirred until uniform and transparent, to obtain a magnesium aluminum silica sol.

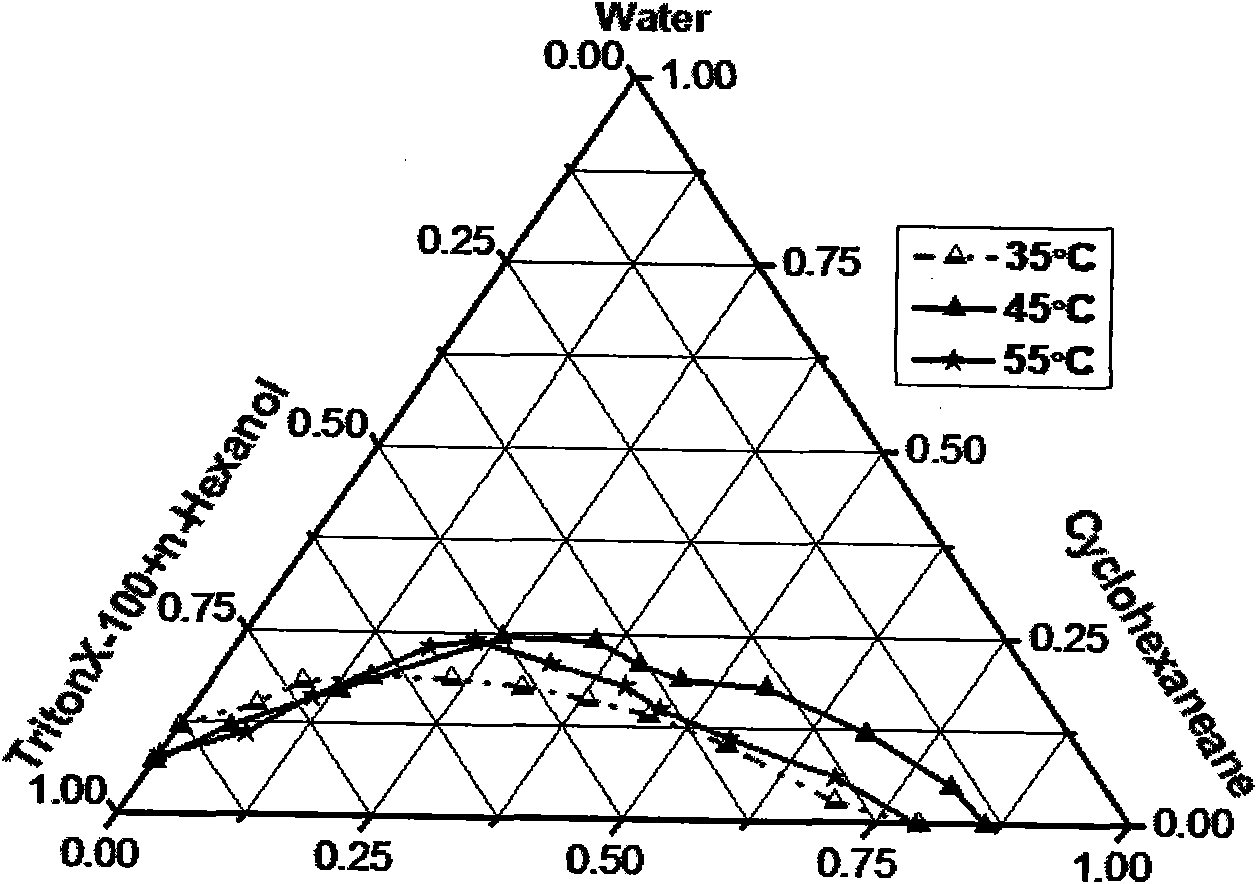

[0022] 2. Preparation of reversed phase (W / O) microemulsion: Triton-100 is used as surfactant, n-hexanol is used as co-surfactant, the mass ratio of Triton-100 to n-hexanol is 2,...

Embodiment 2

[0026] A preparation method of nano cordierite-based ceramic dielectric material for high-frequency chip inductors includes the following steps:

[0027] 1. Preparation of magnesium aluminum silica sol: according to cordierite (Mg 2 Al 4 Si 5 O 18 ), the stoichiometric ratio of aluminum nitrate nonahydrate (Al(NO 3 ) 3 ·9H 2 O), magnesium nitrate hexahydrate (Mg(NO 3 ) 2 ·6H 2 O) Add to water, place it on a magnetic stirrer and stir vigorously. Maintain the temperature at 55°C. Stir for 35 minutes to completely dissolve. Add TEOS and continue stirring to obtain a colorless transparent liquid; then dissolve in 20% Bismuth trioxide (Bi 2 O 3 ) Is added to the colorless and transparent liquid, adjusted to pH 2, and stirred until uniform and transparent, to obtain a magnesium aluminum silica sol.

[0028] 2. Preparation of reverse phase (W / O) microemulsion: Triton-100 is used as surfactant, n-hexanol is used as co-surfactant, the mass ratio of Triton-100 to n-hexanol is 2.5, and cyclohe...

Embodiment 3

[0032] A preparation method of nano cordierite-based ceramic dielectric material for high-frequency chip inductors includes the following steps:

[0033] 1. Preparation of magnesium aluminum silica sol: according to cordierite (Mg 2 Al 4 Si 5 O 18 ), the stoichiometric ratio of aluminum nitrate nonahydrate (Al(NO 3 ) 3 ·9H 2 O), magnesium nitrate hexahydrate (Mg(NO 3 ) 2 ·6H 2 O) Add to water, place it on a magnetic stirrer and stir vigorously. Maintain the temperature at 55°C. Stir for 30 minutes until it is completely dissolved. Add TEOS and continue stirring to obtain a colorless transparent liquid; then dissolve in 25% Bismuth trioxide (Bi 2 O 3 ) Is added to the above colorless and transparent liquid, adjusted to a pH of 2.5, and stirred until uniform and transparent, to obtain a magnesium aluminum silica sol.

[0034] 2. Preparation of reverse phase (W / O) microemulsion: use Triton-100 as surfactant, n-hexanol as auxiliary surfactant, mass ratio of Triton-100 to n-hexanol is 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com