IVB-family element modified CaCu3Ti4O12-based pressure-sensitive material and preparation method thereof

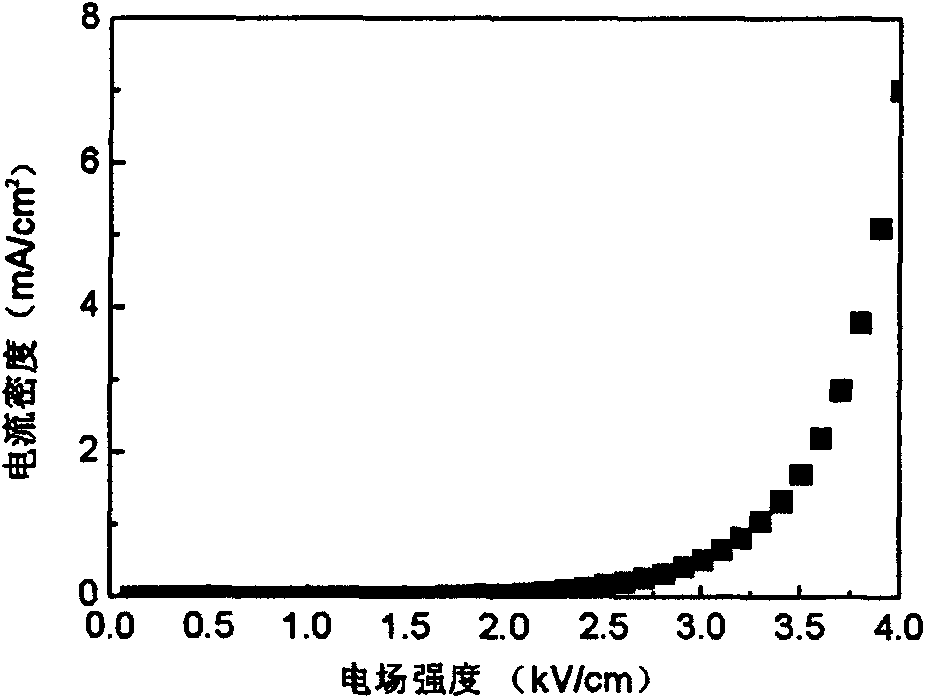

A technology of cacu3ti4-xaxo12 and IVB family, which is applied in the field of CaCu3Ti4O12-based varistor materials and its preparation, can solve the problems of poor performance and large leakage current of varistors, reduce intrinsic conductance, reduce leakage current increase, and reduce leakage The effect of current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

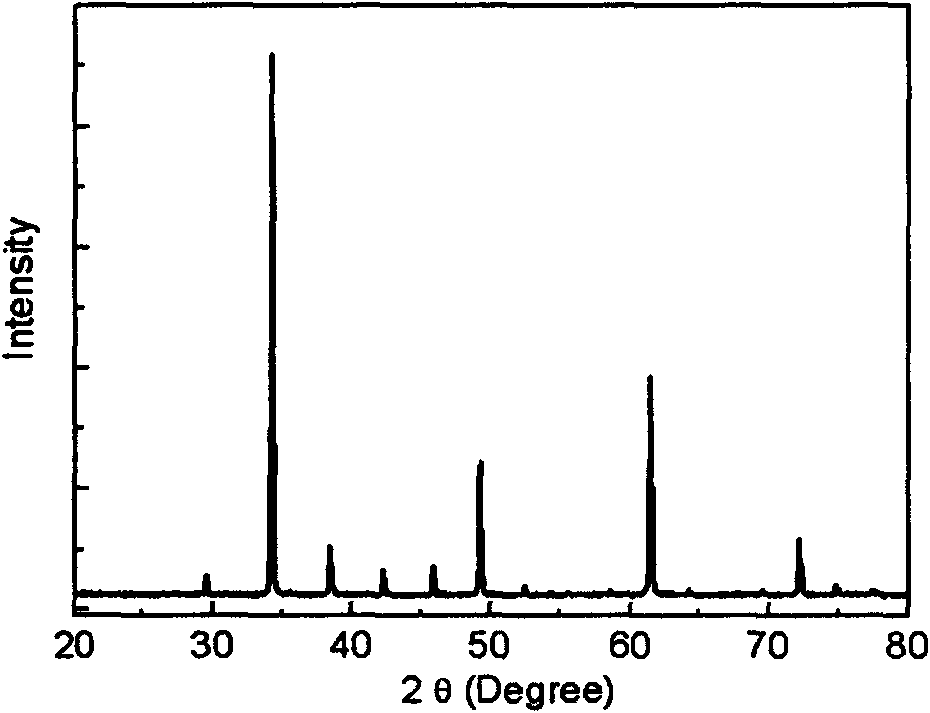

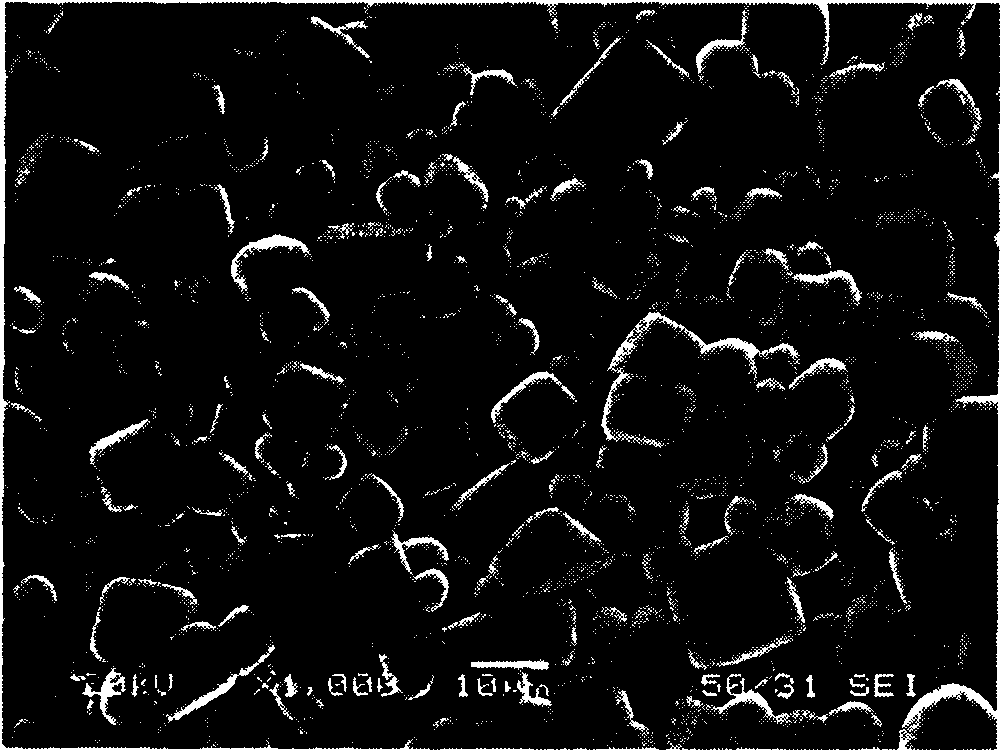

Embodiment 1

[0018] Calcium carbonate with a mass percentage content of 99.0%, copper oxide with a mass percentage content of 99.8%, titanium dioxide with a mass percentage content of 99.0%, and zirconium dioxide with a mass percentage content of 99.0% are used to analyze the pure grade. The stoichiometric ratio is CaCu 3 Ti 3.9 Zr 0.1 o 12 ingredients. The prepared materials are put into a ball mill and mixed according to the ratio of zirconia balls:materials at 10:1, and no other medium is added during the mixing process. The time of ball milling is 6 hours, the rotating speed is 400 rpm, and the mixed material briquettes are pre-fired at 900°C for 2 hours; 6 hours, through a 40-mesh sieve; add the powder to its mass ratio of 32% pure water, mass ratio of 1.2% polyacrylic acid ammonia dispersant and mass ratio of 8% polyvinyl alcohol binder, and mix for 2 hours by ball milling The slurry is uniformly formed, the ball milling speed is 100 rpm, and the airflow spray granulation is adop...

Embodiment 2

[0020] Calcium carbonate with a mass percentage content of 99.0% of the analytically pure grade, copper oxide with a mass percentage content of 99.8%, titanium dioxide with a mass percentage content of 99.0%, and hafnium dioxide with a mass percentage content of 99.0%, the stoichiometric ratio is CaCu 3 Ti 3.6 f 0.4 o 12 ingredients. The prepared materials are put into a ball mill and mixed according to the ratio of zirconia balls:materials at 15:1, and no other medium is added during the mixing process. The time of ball milling is 12 hours, the rotating speed is 300 rpm, and the mixed material briquette is pre-fired at 1000°C for 2.5 hours; After 12 hours, pass through a 40-mesh sieve; add the powder to 25% by mass of pure water, 1.8% by mass of polyacrylic acid ammonia dispersant and 6% by mass of polyvinyl alcohol binder, and mix by ball milling for 1 hour The slurry is uniformly formed, the ball milling speed is 250 rpm, and the airflow spray granulation is adopted; th...

Embodiment 3

[0022]Calcium carbonate with an analytically pure grade content of 99.0% by mass, copper oxide with a mass percentage of 99.8%, titanium dioxide with a mass percentage of 99.0%, zirconia with a mass percentage of 99.0%, and 99.0% by mass Hafnium dioxide, stoichiometric to CaCu 3 Ti 3.2 Zr 0.4 f 0.4 o 12 ingredients. The prepared materials are put into a ball mill and mixed according to the ratio of zirconia balls:materials at 6:1, and no other medium is added during the mixing process. The time of ball milling is 10 hours, the rotating speed is 400 rpm, and the mixed material briquettes are pre-fired at 1150°C for 1.5 hours; After 10 hours, cross a 40-mesh sieve; add the powder to its mass ratio of 15% pure water, the mass ratio of 0.5% polyacrylic acid ammonia dispersant and the mass ratio of 7% polyvinyl alcohol binder, through ball milling for 2 Mix evenly for 1 hour to form a slurry, the ball milling speed is 150 rpm, and the airflow spray granulation is used; the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com