Preparation method of water dispersed modified acrylic ester resin for automobile finish varnish

An acrylate, dispersion-based technology, applied in the direction of coating etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

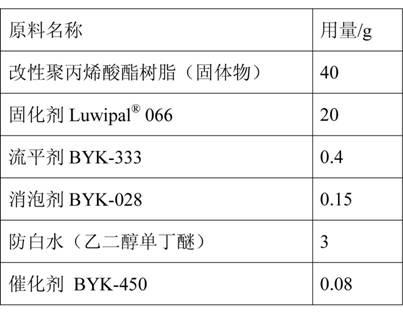

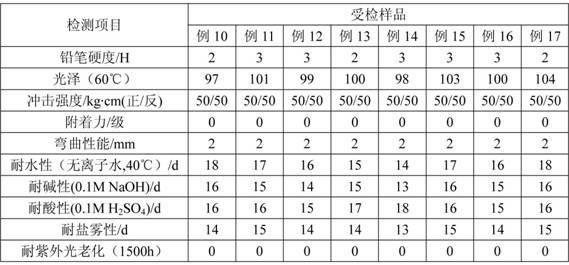

Examples

preparation example Construction

[0022] The preparation method of water dispersion type modified acrylate coating resin of the present invention, comprises the steps:

[0023] Dissolving part of the initiator in the vinyl monomer;

[0024] Add modifier and co-solvent into the reactor, raise the temperature to 110°C under the protection of nitrogen, add vinyl monomers dropwise, and complete the dropwise addition within 1 to 4 hours, and keep warm for 0 to 1 hour;

[0025] Add the additional initiator dissolved in the co-solvent dropwise, complete the dropwise addition within 30 minutes, and keep the reaction for 1 to 4 hours;

[0026] Cool down to 70°C, add a neutralizer dropwise until the neutralization degree is 80%, and discharge to obtain a water-dispersed modified acrylate coating resin.

[0027] The neutralizing agent used is a conventional neutralizing agent, including ethylamine, propylamine, benzylamine, dimethylamine, dibutylamine, dimethylaniline, diethylaniline, dimethylethanolamine, trimethylamin...

Embodiment 1

[0036] Add 39.5g of acetoacetyl tert-butyl ester and 27.3g of Boltorn with 16 terminal hydroxyl numbers in a 100ml three-necked flask equipped with a water separator and a reflux condenser. TMH20, the temperature was raised to 120°C while nitrogen flow was passed, and after 1.5 hours of reaction, the conversion rate was calculated to be 99% based on the mass of tert-butanol collected by the water separator, and the product was a transparent liquid.

[0037] In a 500ml four-neck flask equipped with a stirrer, condenser, thermometer and oil bath heating device, add 5g of acetoacetyl-blocked Boltorn TM H20, 25g propylene glycol monomethyl ether and 15g isopropanol, stir evenly, and heat up to 100°C under nitrogen protection;

[0038] Mix 22 g methyl methacrylate, 12 g styrene, 40 g butyl acrylate, 10 g isobornyl methacrylate, 10 g hydroxyethyl methacrylate, 6 g acrylic acid, 1 g dibenzoyl peroxide (BPO) and 1 g dodeca Add alkyl mercaptan to a Erlenmeyer flask, mix evenly, after ...

Embodiment 5

[0043] Add 31.6g of acetoacetyl tert-butyl ester and 6.8g of pentaerythritol into a 100ml three-necked flask equipped with a water separator and a reflux condenser, raise the temperature to 110°C while flowing nitrogen, and collect tert-butyl with a water separator after reacting for 3 hours The quality of alcohol calculates that the conversion rate is 99%, and the product is a transparent liquid.

[0044] In a 500ml four-neck flask equipped with a stirrer, condenser, thermometer and oil bath heating device, add 5g of acetoacetyl-capped pentaerythritol, 25g of propylene glycol monomethyl ether and 15g of isopropanol, stir well, and heat up under nitrogen protection to 100°C;

[0045] Add 22g of methyl methacrylate, 12g of styrene, 40g of butyl acrylate, 10g of isobornyl methacrylate, 10g of hydroxyethyl methacrylate, 6g of acrylic acid, 1g of BPO and 1g of dodecyl mercaptan into an Erlenmeyer flask , mix evenly, after the BPO dissolves, use a separatory funnel to drop it into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com