Polyurethane elastomer

A technology of polyurethane elastomer and prepolymer, applied in the field of polyurethane elastomer, can solve problems such as difficulty in meeting the requirements of special fields, and achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

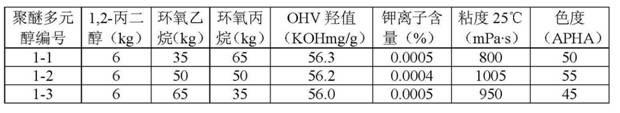

[0023] Example 1 Preparation of polyether polyols:

[0024] The polyether polyol in the present invention is obtained by adopting known ionic ring-opening polymerization method, and the specific method is: add 1,2-propylene glycol, potassium hydroxide 0.2% (based on the total amount of feed, potassium hydroxide The addition amount of 1,2-propanediol, propylene oxide and ethylene oxide is 0.2% of the total weight), nitrogen is replaced 3 times, then vacuumized, the temperature is raised to 80°C, and then propylene oxide and ethylene oxide are slowly added , the reaction pressure was kept below 0.44MPa, the reaction temperature was controlled at 115±2°C, and after 4 hours of reaction, the temperature was lowered to 80-90°C, and samples were taken to measure the hydroxyl value to obtain crude polyether. After measuring its hydroxyl value in the range of 55-57KOHmg / g, add an appropriate amount of pure water, 1.2% phosphoric acid, and 0.5% magnesium silicate (based on the total fe...

Embodiment 2

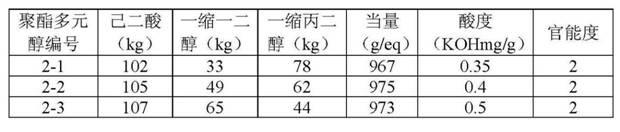

[0027] Example 2 Preparation of polyester polyol :

[0028] The polyester polyol among the present invention adopts known polycondensation method to obtain, and the method that adopts is vacuum dehydration method. Weigh adipic acid, diethylene glycol and dipropylene glycol according to the proportion shown in Table 2, put the above-mentioned substances into the reaction kettle, first pass nitrogen gas for 10 minutes, remove the air in the system, and then heat under the protection of nitrogen gas And stirring, after the material is melted, 0.1% of the total weight of the material is added as a catalyst tetrabutyl titanate. Water begins to flow out at about 140°C, continue heating, and the theoretical water is finished when the temperature in the reactor reaches about 220°C. Keep warm for 2 hours after the water comes out, then stop the nitrogen flow. Start vacuuming step by step, the vacuum degree is 20kPa, 1h; 13.2kPa, 1h; 6.7kPa, 1h, sampling and analyzing acid. Then e...

Embodiment 3

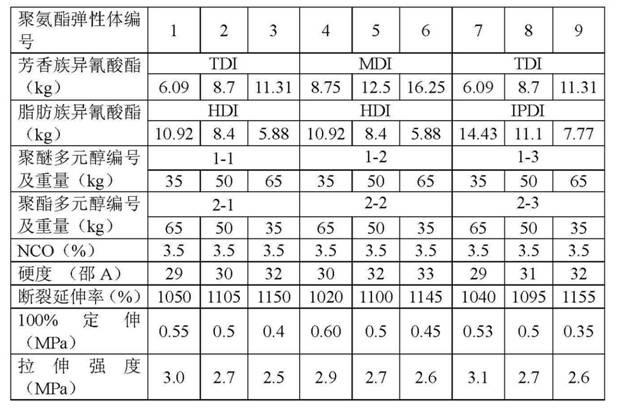

[0033] The invention adopts the known prepolymer method to prepare the polyurethane elastomer, that is, first prepares the isocyanate prepolymer, and then performs chain extension to obtain the polyurethane elastomer.

[0034] The first step: dehydrate the composite polyol (the polyether polyol and polyester polyol prepared in Examples 1 and 2 are mixed in the ratio shown in Table 3) at 100-130°C for 2-3 hours in vacuum, then cool to 50- 60°C, quickly add liquid diisocyanate (2 to 5 times the molar weight of the compound polyol, see Table 3) under rapid stirring, after 30 to 40 minutes, keep the reaction at 80 to 85°C for 2 to 3 hours, and take samples to analyze the free The content of isocyanate group is vacuum degassed for 20-30 minutes, and sealed and stored for later use.

[0035] Step 2: Weigh 80-100g of isocyanic acid prepolymer, stir and heat up to 80-85°C, vacuum defoaming for 1-2min, add chain extender MOCA equivalent to NCO under rapid stirring, and stir for about 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com