Polymer type phosphorous flame retardant containing DOPO and preparation method thereof

A polymer and flame retardant technology, applied in the field of polymer-type phosphorus-containing flame retardants and their preparation, can solve the problems of poor polymer matrix compatibility, leaching, and large environmental pollution, and achieve good expansion into Carbon, good flame retardant effect, high phosphorus content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

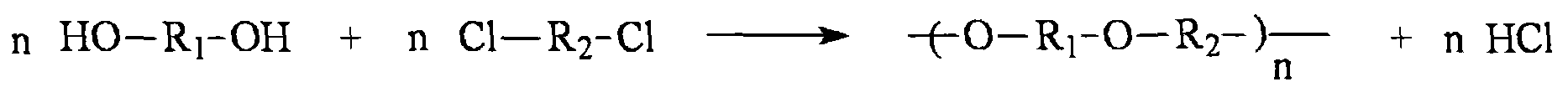

Method used

Image

Examples

Embodiment 1

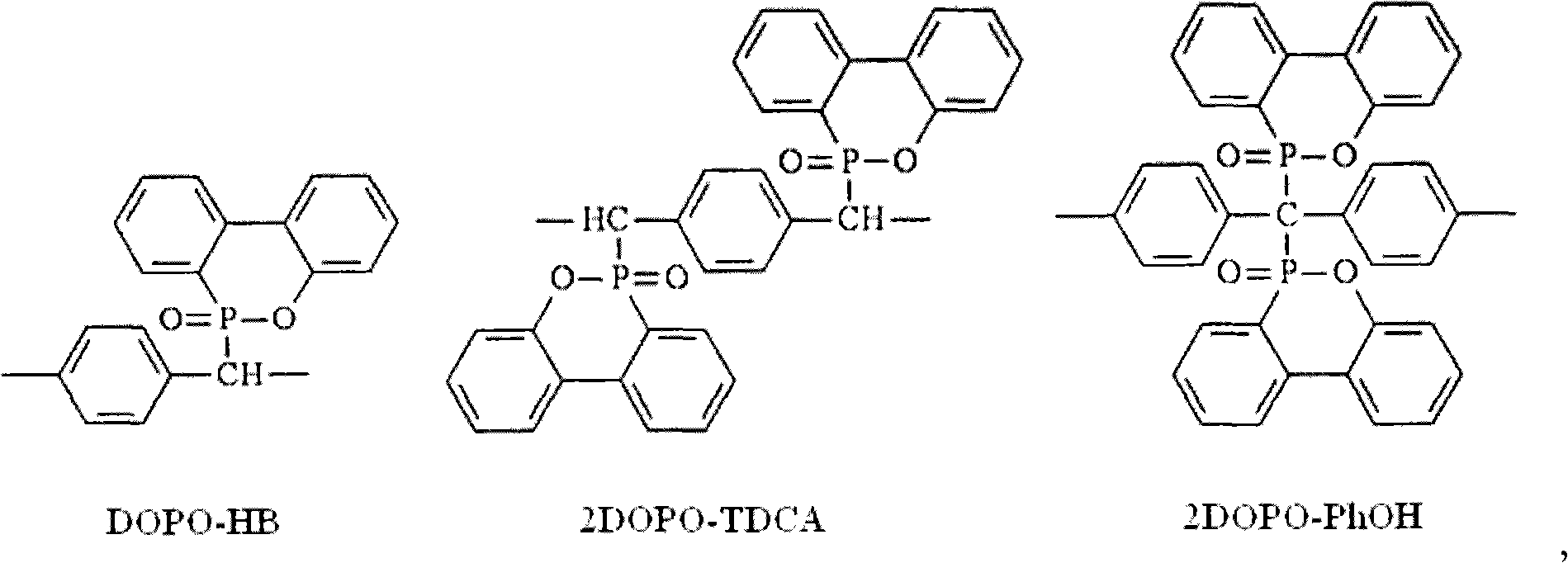

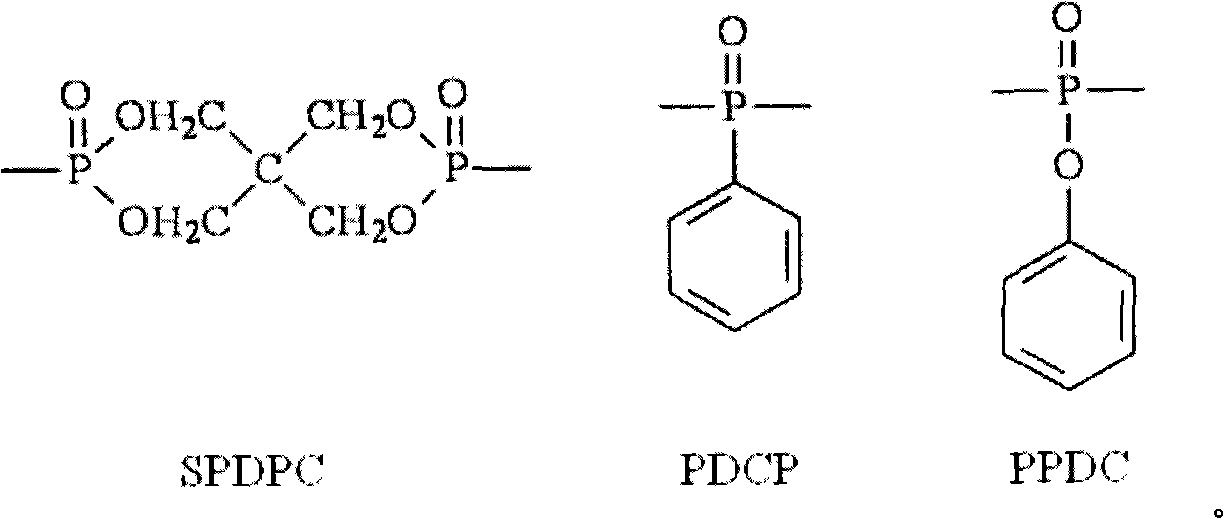

[0030] Add 29.7g of pentaerythritol diphosphate diphosphoryl chloride, 250ml of anhydrous acetonitrile and 37.2g of 9,10-dihydro-9-oxa-10-phosphorus in a 500ml three-neck flask equipped with a stirrer, nitrogen inlet and condenser Heterophenanthrene-10-oxide-p-hydroxybenzyl alcohol (DOPO-HB), heated to 80 °C under the protection of nitrogen atmosphere, reacted under continuous stirring until no HCl gas was released, cooled to room temperature, and removed the solvent under reduced pressure to obtain White solid product in 90% yield.

[0031] Infrared analysis is carried out to the obtained product, in pentaerythritol diphosphate diphosphoryl chloride, 583-541cm -1 The characteristic peak of P-Cl bond disappears at 929, 1189cm -1 P-O-Ph characteristic peak at 1442cm -1 P-Ph characteristic peak appears. exist 1 In the HNMR spectrogram, the alcoholic hydroxyl group at 6.2 ppm and the phenolic hydroxyl group at 9.35 ppm of the product disappeared. It can be seen that the prod...

Embodiment 2

[0034] Add 29.7g of pentaerythritol diphosphate diphosphoryl chloride, 250ml of anhydrous acetonitrile and 62.2g of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10- Oxide-tere-phenylenedimethanol (2DOPO-TDCA), heated to 80°C under the protection of nitrogen atmosphere, reacted under continuous stirring until no HCl gas was released, cooled to room temperature, and removed the solvent under reduced pressure to obtain a white solid product, product The rate reached 86%.

[0035] Infrared analysis is carried out to the obtained product, in pentaerythritol diphosphate diphosphoryl chloride, 583-541cm -1 The characteristic peak of P-Cl bond disappears at 929, 1189cm -1 P-O-Ph characteristic peak at 1442cm -1 P-Ph characteristic peak appears. exist 1 In the HNMR spectrogram, the aldehyde absorption peak of the product at 10.0 ppm disappeared. It can be seen that the product is a polymer-type phosphorus-containing flame retardant containing 9,10-dihydro-9-oxa-10-phosphaphenanthrene...

Embodiment 3

[0038] Add 29.7g of pentaerythritol diphosphate diphosphoryl chloride, 150ml of anhydrous acetonitrile and 69.1g of 9,10-dihydro-9-oxa-10-phosphorus in a 500ml three-necked flask equipped with a stirrer, nitrogen inlet and condenser Heterophenanthrene-10-oxide-dihydroxydiphenylmethane (2DOPO-PhOH), heated to 80°C under the protection of nitrogen atmosphere, reacted under continuous stirring until no HCl gas was released, cooled to room temperature, and removed the solvent under reduced pressure, The product was obtained as a white solid in 83% yield.

[0039] Infrared analysis is carried out to the obtained product, in pentaerythritol diphosphate diphosphoryl chloride, 583-541cm -1The characteristic peak of P-Cl bond disappears at 929, 1189cm -1 P-O-Ph characteristic peak at 1442cm -1 P-Ph characteristic peak appears. It can be seen that the product is a polymer-type phosphorus-containing flame retardant containing 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal decomposition temperature | aaaaa | aaaaa |

| Maximum thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com