Decomposition maturing agent for degrading straw

A technology of decomposing agent and straw, which is applied in the field of straw decomposing agent, can solve the problems of difficult to meet the needs of agricultural production, high temperature of decomposed straw, and unstable decomposition, so as to reduce pests and weeds and pollution, reduce crop diseases, and be good The effect of the control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

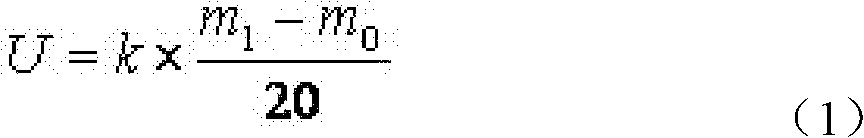

Method used

Image

Examples

Embodiment 1

[0022] Example 1 Preparation of straw decomposing agent and detection of enzyme activity 1 Preparation of decomposing agent The decomposing agent used in this example to degrade straw consists of bacterial agent A, bacterial agent B, bacterial agent C and bacterial agent D. Bacterial agent A, bacterial agent B, bacterial agent C and bacterial agent D were prepared according to the following method: strain medium: rice bran 0.6g / L, bran 0.2g / L, straw powder 0.8g / L, soybean meal 0.4g / L, pH 7.0.

[0023] Candida tropicalis was cultivated in the culture medium of the above-mentioned strains at 28° C. and shaken at 200 r / min for 3 days. All the fermentation broth was collected and dried under low-temperature negative pressure as bacterial agent A.

[0024] Aspergillus oryzae was cultivated in the culture medium of the above-mentioned strains at 28° C. and shaken at 200 r / min for 3 days, and all the fermentation broth was collected and dried under low-temperature negative pressure a...

Embodiment 2

[0055] Example 2 Preparation of decomposing agent for degrading straw The decomposing agent used in this example for degrading straw includes bacterial agent A, bacterial agent B, bacterial agent C and bacterial agent D. Bacterial agent A, bacterial agent B, bacterial agent C and bacterial agent D were prepared according to the following method: strain medium: rice bran 0.6g / L, bran 0.2g / L, straw powder 0.8g / L, soybean meal 0.4g / L , pH 7.0.

[0056] Candida tropicalis was cultivated in the culture medium of the above-mentioned strains at 28° C. and shaken at 200 r / min for 3 days. All the fermentation broth was collected and dried under low-temperature negative pressure as bacterial agent A.

[0057] Aspergillus oryzae was cultivated in the culture medium of the above-mentioned strains at 28° C. and shaken at 200 r / min for 3 days, and all the fermentation broth was collected and dried under low-temperature negative pressure as bacterial agent B.

[0058] Trichoderma viride was...

Embodiment 3

[0062] Embodiment 3 is used for the preparation of decomposing agent for degrading stalks except that the following technical characteristics are different, and other processes are all consistent with embodiment 1: Candida tropicalis (Candidatropicalis) in bacterial agent A, Aspergillus oryzae (Aspergillus oryzae) in bacterial agent B 1. The colony-forming unit (CFU) ratio of Trichodermaviride in bacterial agent C to Bacillus subtilis in bacterial agent D is 10:0.1:10:0.1.

[0063] The enzyme activity of the straw decomposing agent prepared in this example was measured by the method of Example 1, and the measurement results showed that the straw decomposing agent of the present invention had very high cellulase activity, protease activity and amylase activity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com