Molecular imprinted polymer, preparation method and application thereof

A technology of ursodeoxycholic acid and porous silica gel, which is applied in the field of molecularly imprinted polymers to achieve the effects of large specific surface area, stable chemical properties and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

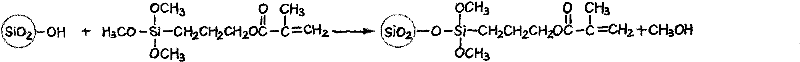

Method used

Image

Examples

Embodiment 1

[0039] Example 1 Preparation of ursodeoxycholic acid molecularly imprinted polymers on porous silica surface by initiating polymerization in solution

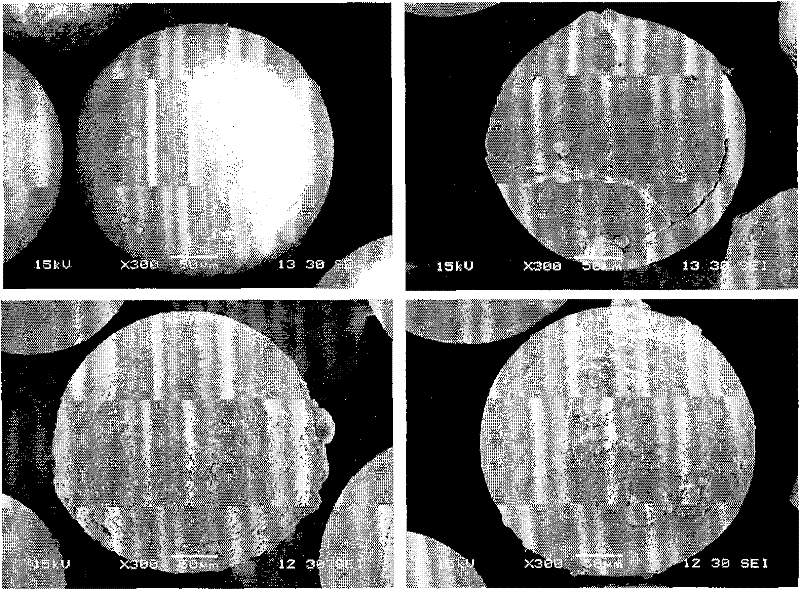

[0040] (1) Activation of silica gel

[0041] Weigh about 50g of coarse-porous microsphere silica gel (80-100 mesh) into a 500ml round bottom flask, add 200ml of nitric acid aqueous solution with a volume ratio of 1:1 and soak for 24h, or condense and reflux on a heating mantle for 8h to increase the amount of silica gel The number of surface hydroxyl groups. Stand overnight, remove the acid solution by suction filtration with a sand core funnel, then wash with deionized water until the pH is neutral, then wash the silica gel with methanol to remove organic impurities in the silica gel, and then collect the silica gel in a vacuum oven at 60°C for drying Finally, place the dried silica gel in an infrared electric oven and activate it at 110°C for 12 hours to remove the physical water on the silica gel surface. The scanning el...

Embodiment 2

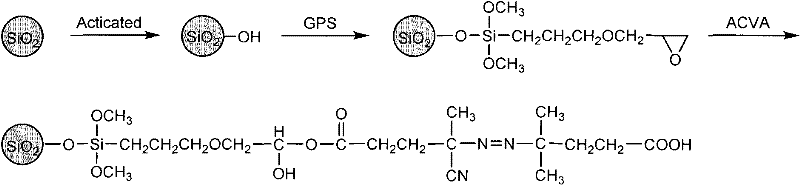

[0048] Example 2 Preparation of ursodeoxycholic acid molecularly imprinted polymer on porous silica surface by initiating polymerization on silica gel surface

[0049] (1) Activation of silica gel: with embodiment 1 (1).

[0050] (2) Functional modification of silica gel surface

[0051] Weigh 12g of activated silica gel, add it to a 250mL Erlenmeyer flask with a stopper, add 100ml of toluene, 20mmol of γ-glycidyl ether propyl trimethoxysilane (GPS) and 1ml of triethylamine, and oscillate ultrasonically for 5min in an ultrasonic cleaner , so that the solution system is fully mixed, and the silica gel is fully dispersed in the solution. The system was ventilated with nitrogen for 10 minutes, then sealed, placed in a water-bath shaker at 80° C., and reacted at 280 rpm for 24 hours. After the reaction was completed, the reaction solution was removed by suction filtration with a sand core funnel, washed with toluene, ether, and acetone several times in sequence to remove resid...

Embodiment 3

[0056] Example 3 Adsorption kinetics test

[0057] Prepare a solution of UDCA in acetone with a concentration of 1 mg / ml. Weigh 0.5g of the imprinted polymers prepared in Example 1 and Example 2 respectively and place them in a 100ml conical flask with a stopper, add 40ml of prepared UDCA acetone solution respectively, place them in a 150rpm air bath shaker at room temperature to vibrate and adsorb, and The supernatant was taken to measure the concentration of UDCA, and the adsorption amount of the imprinted polymer to the template molecule was calculated at different times. The imprinted polymer prepared by the present invention can reach adsorption equilibrium after adsorption for 12 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com