Hydrophobic wear-resistant and corrosion-resistant paint and method for preparing same

An anti-corrosion coating and manufacturing method technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve coating damage, anti-corrosion coatings are not ideal for sea sand erosion, do not consider hydrophobic properties, etc. problem, to achieve the effect of hard coating, increase water repellency, and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

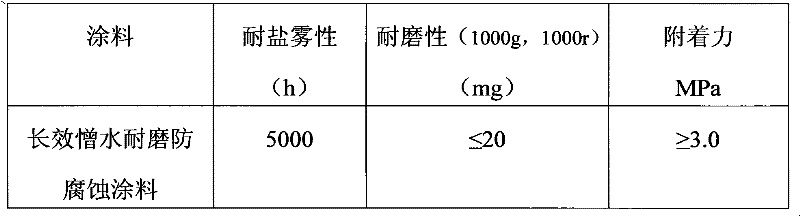

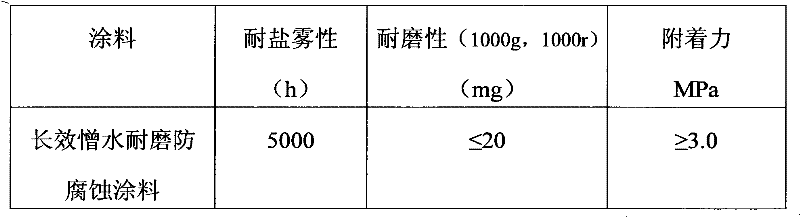

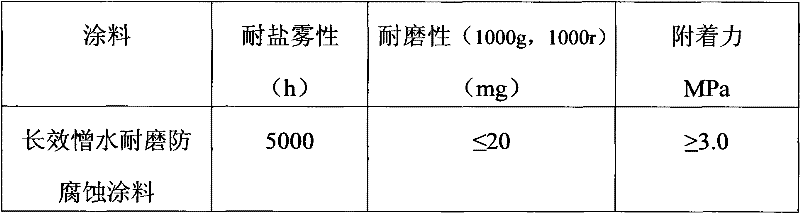

Examples

Embodiment 1

[0019] The long-acting hydrophobic, wear-resistant and anti-corrosion paint for marine structures and its manufacturing method are disclosed in the present invention.

[0020] In the stainless steel feed barrel, add 1 weight part E-44 type epoxy resin earlier, add the 963 acrylic acid that the xylene of 0.25 weight part, the butyl acetate of 0.1 weight part, 0.1 weight part of Jiangsu Sanmu Chemical Co., Ltd. Resin, 0.2 parts by weight of benzofuran-indene resin are uniformly dispersed and mixed at a high speed, then add 0.050 parts by weight of titanium dioxide, 0.15 parts by weight of spherical ceramic powder, 0.05 parts by weight of precipitated barium sulfate, 0.005 parts by weight of The methylethanolamine of weight part, the Efka 3600 of 0.005 weight part ( 3600), 0.005 parts by weight of Efka 5065 ( 5065), then stirred at a high speed for 30 minutes and then ground it with a sand mill for 0.5-1 hour to obtain component A.

[0021] In another stainless steel bucket, ...

Embodiment 2

[0025] The long-acting hydrophobic, wear-resistant and anti-corrosion coating for marine structures and its manufacturing method are disclosed in the present invention.

[0026] In the stainless steel bucket, add 1 weight part E-42 type epoxy resin earlier, then add the dimethylbenzene of 0.35 weight part, the butyl acetate of 0.15 weight part, the A160 acrylic resin that the German Bayer company of 0.2 weight part produces , 0.4 parts by weight of benzofuran-indene resin after high-speed dispersion and mixing, adding 0.1 parts by weight of titanium dioxide, 0.25 parts by weight of spherical ceramic powder, 0.1 parts by weight of precipitated barium sulfate, 0.02 parts by weight of Parts of methylethanolamine, 0.02 parts by weight of Efka 3600 ( 3600), 0.02 parts by weight of Efka 5065 ( 5065), then stirred at a high speed for 30 minutes and then ground it with a sand mill for 0.5-1 hour to obtain component A.

[0027] In another stainless steel bucket, add 1 weight part o...

Embodiment 3

[0031] The long-acting hydrophobic, wear-resistant and anti-corrosion coating for marine structures and its manufacturing method are disclosed in the present invention.

[0032] In the stainless steel feed barrel, add 1 weight part E-42 type epoxy resin earlier, then add the 963 acrylic acid that the xylene of 0.3 weight part, the butyl acetate of 0.13 weight part, 0.15 weight part of Jiangsu Sanmu Chemical Co., Ltd. After the coumarone-indene resin of resin, 0.28 weight part is dispersed and mixed at a high speed, under the situation of stirring, successively add 0.07 weight part of titanium dioxide, 0.2 weight part of spherical ceramic powder, 0.07 weight part of precipitated barium sulfate, 0.01 The methylethanolamine of weight part, the Efka 3600 of 0.015 weight part ( 3600), 0.015 parts by weight of Efka 5065 ( 5065), then stirred at a high speed for 30 minutes and then ground it with a sand mill for 0.5-1 hour to obtain component A.

[0033] In another stainless stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com