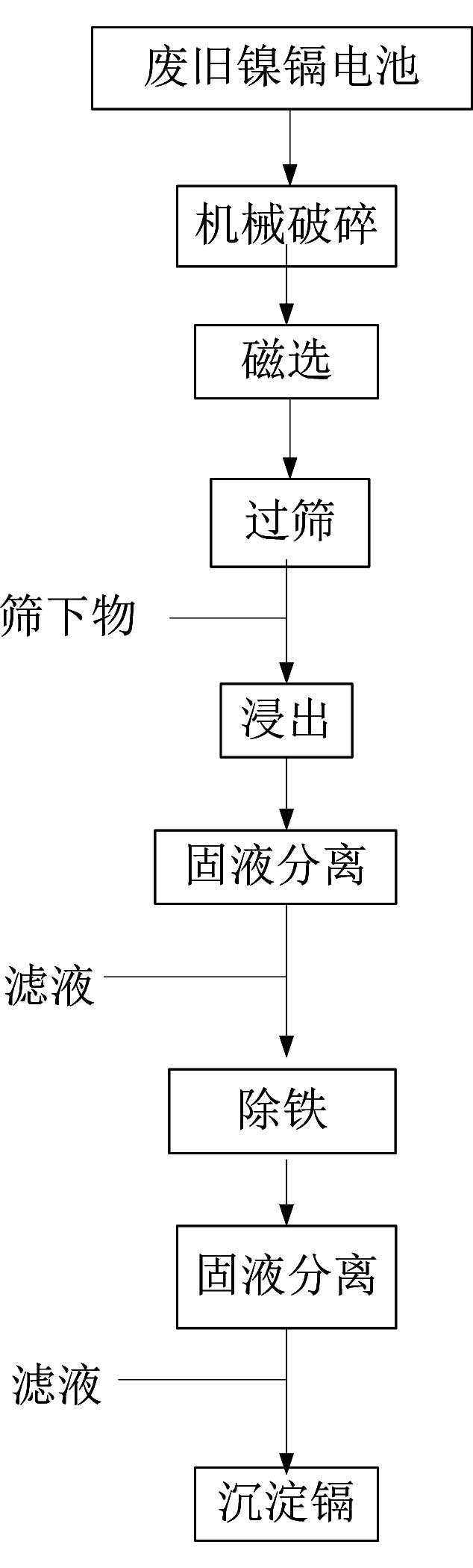

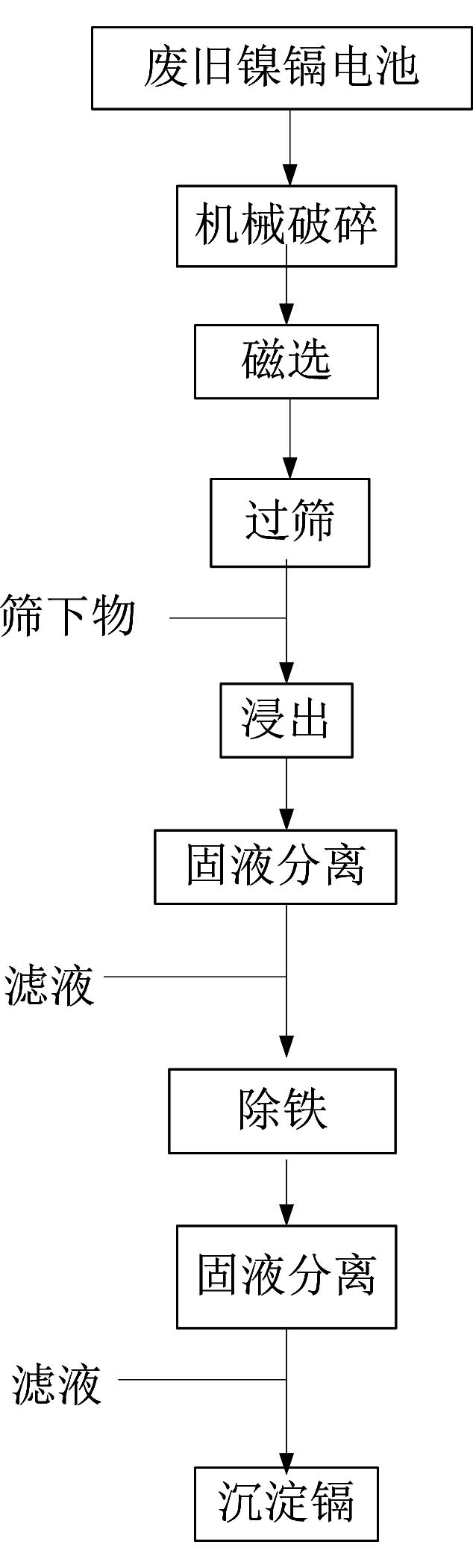

Method for recovering cadmium from waste nickel-cadmium battery

A waste battery, nickel-cadmium technology, applied in the field of waste battery recycling, can solve the problems of complex leaching equipment, long recycling process route, large equipment investment, etc., and achieves a simple and easy recycling method, less equipment investment, and high economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Put 1000kg of powder into the dissolution kettle, add 5000L of water, 10000mol of sulfuric acid, 6000mol of oxidant sodium chlorate, heat up to 50°C, stir and soak for 3 hours, and take the leachate;

[0036] 2) Add waste nickel hydroxide, adjust the pH of the leaching solution to 3.5, remove iron, and separate solid and liquid;

[0037] 3) After the leachate after solid-liquid separation is passed into H 2 S gas to precipitate cadmium element.

[0038] After testing, the recovery rate of cadmium was 99.8%.

Embodiment 2

[0040] 1) Put 1000kg powder into the dissolution kettle, add 3000L water, 10000mol hydrochloric acid, 10000mol oxidant H 2 o 2 , heated up to 80°C, stirred and soaked for 1 hour, and took the leachate;

[0041] 2) adding sodium hydroxide solution, adjusting the pH of the leaching solution to 5, removing iron, and separating solid and liquid;

[0042] 3) Sodium sulfide is added to the leaching solution after solid-liquid separation to precipitate cadmium element.

[0043] After testing, the recovery rate of cadmium was 99.5%.

Embodiment 3

[0045] 1) Put 1000kg of powder into the dissolution kettle, add 4500L of water, 7500mol of sulfuric acid, and 8000mol of oxidant sodium persulfate, heat up to 60°C, stir and soak for 2 hours, and take the leachate;

[0046] 2) adding sodium carbonate, adjusting the pH of the leachate to 3, iron removal, solid-liquid separation;

[0047] 3) After the leachate after solid-liquid separation is passed into H 2 S gas to precipitate cadmium element.

[0048] After testing, the recovery rate of cadmium was 99.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com