Hydroxyapatite with hollow sphere structure and preparation method thereof

A technology of hydroxyapatite and hollow spheres, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., and can solve the problem of low yield of hydroxyapatite hollow microspheres, unfavorable industrialization and application, and large pH changes of reactants and other problems, to achieve the effect of facilitating industrialization, easy control of process conditions, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

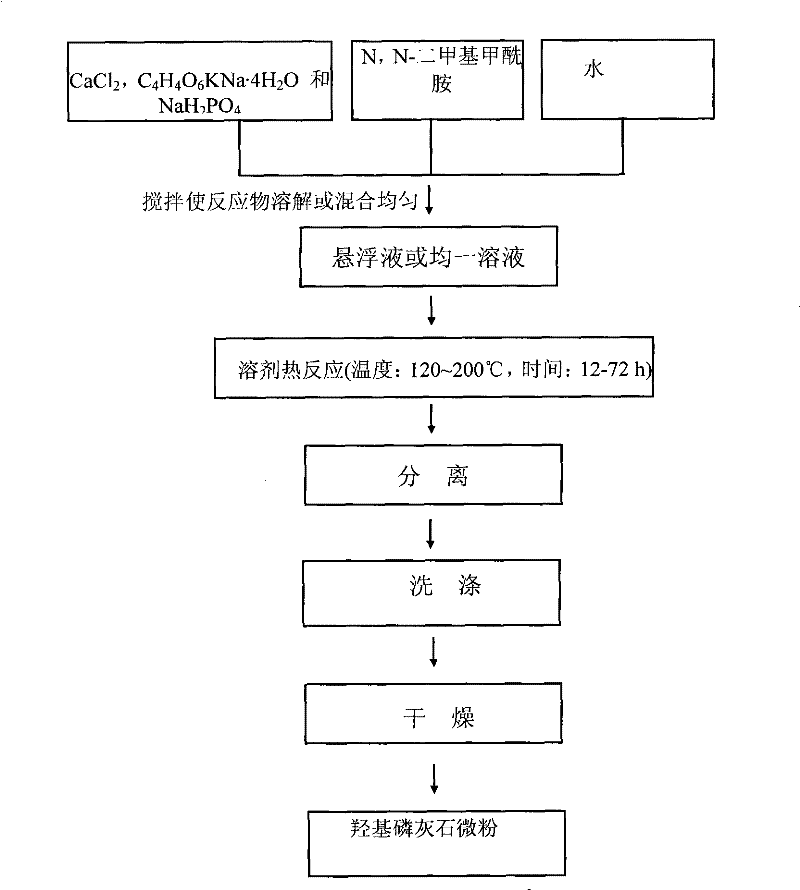

[0044] 1. At room temperature, add 0.110g CaCl 2 , 0.282g potassium sodium tartrate (C 4 h 4 o 6 KNa·4H 2 O) and 0.094g NaH 2 PO 4 2H 2 O was added to 4 mL of distilled water, then 11 mL of N,N-dimethylformamide was added and stirred to obtain a uniformly dispersed suspension.

[0045] 2. Transfer all the suspension into a 20mL autoclave and seal it. Put the sealed autoclave into an oven, heat it to 200°C, and keep it warm at this temperature for 24 hours.

[0046] 3. After the autoclave was naturally cooled to room temperature, the product was taken out, and the product was separated by centrifugation. The obtained precipitate was washed twice with absolute ethanol and distilled water, and then vacuum-dried at 60°C. The degree of vacuum is -0.08MPa, and the hydroxyapatite with hollow sphere structure of the present invention is prepared.

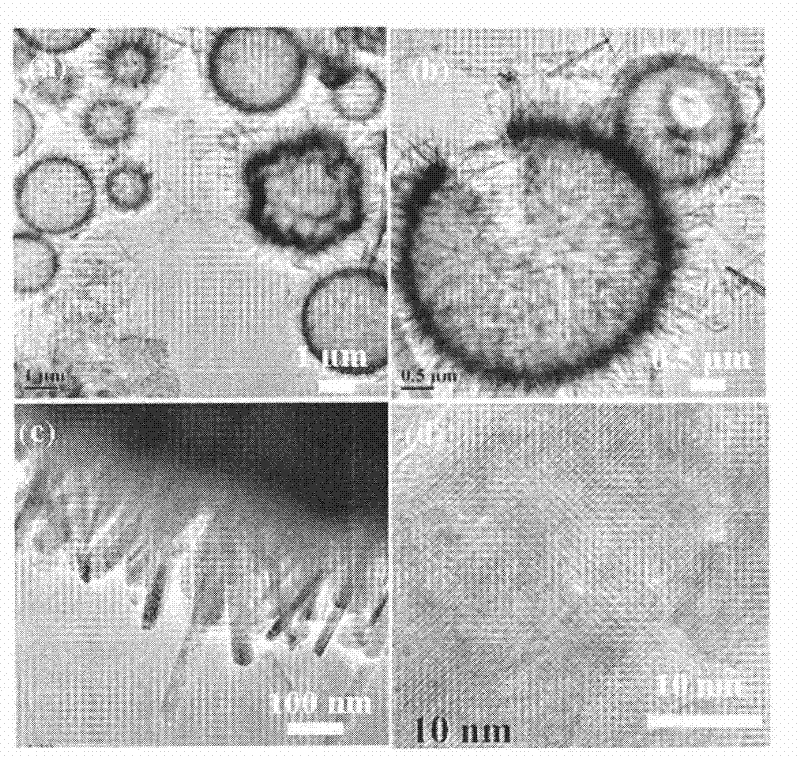

[0047] The morphology of the prepared hollow sphere-structured hydroxyapatite was detected by scanning electron microscopy, and t...

Embodiment 2

[0054] Except that the reactant is 0.176g C 4 h 6 o 4 Ca·H 2 O, 0.141g potassium sodium tartrate (C 4 h 4 o 6 KNa·4H 2 O) and 0.054g KH 2 PO 4 5ml of distilled water and 10ml of N,N-dimethylformamide were used for the reaction; the reaction temperature was 150°C and the reaction time was 48h, and the rest were the same as in Example 1.

[0055] The morphology of the prepared hollow sphere-structured hydroxyapatite was detected by scanning electron microscopy, and the detection results are shown in Table 1.

[0056] The specific surface (Brunauer-Emmett-Teller, BET) of the prepared hydroxyapatite hollow spheres was tested with a specific surface tester (JW-04, China), and the test results are shown in Table 1.

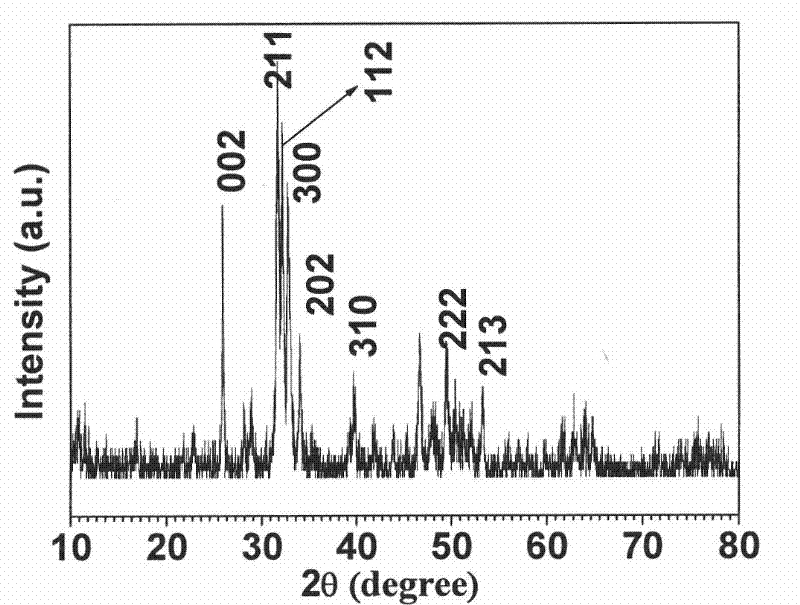

[0057] The X-ray diffraction spectrum of the prepared hydroxyapatite hollow spheres is completely consistent with the standard JCPDS card (No.84-1998).

Embodiment 3

[0059] Except that the reactant is 0.236g Ca(NO 3 ) 2 4H 2 O, 0.423g potassium sodium tartrate (C 4 h 4 o 6 KNa·4H 2 O) and 0.183g K2 HPO 4 ·3H 2 O; 6ml of distilled water for reaction, 9ml of N,N-dimethylformamide; the reaction temperature is 120°C, and the reaction time is 72h, and the rest are the same as in Example 1.

[0060] The morphology of the prepared hollow sphere-structured hydroxyapatite was detected by scanning electron microscopy, and the detection results are shown in Table 1.

[0061] The specific surface (Brunauer-Emmett-Teller, BET) of the prepared hydroxyapatite hollow spheres was tested with a specific surface tester (JW-04, China), and the test results are shown in Table 1.

[0062] The X-ray diffraction spectrum of the prepared hydroxyapatite hollow spheres is completely consistent with the standard JCPDS card (No.84-1998).

[0063] Table 1 Performance test results of hydroxyapatite hollow spheres

[0064] Hollow sphere particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com