Porous silicon-based cathode for lithium battery and preparation method thereof

A lithium-ion battery, porous silicon-based technology, used in battery electrodes, circuits, electrical components, etc., can solve problems such as damage to the internal structure of materials, affecting the cycle performance of electrode materials, and achieve low usage, improved capacity and high current. Discharge performance, effect of improving insertion and extraction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

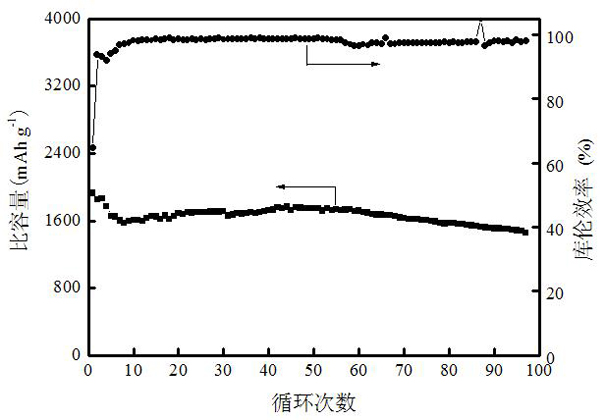

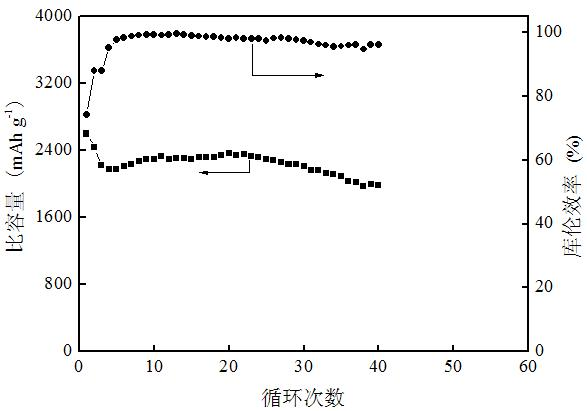

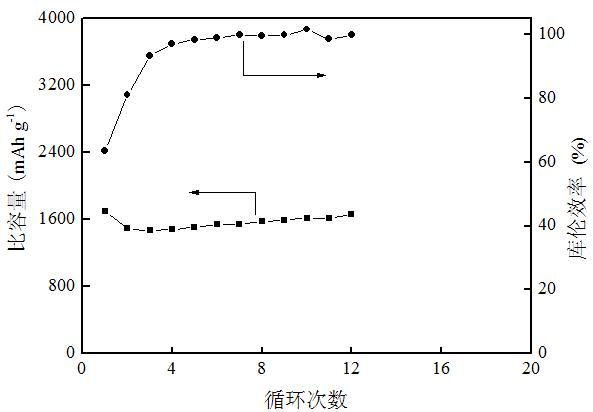

Image

Examples

specific Embodiment approach 1

[0014] Embodiment 1: The porous silicon-based negative electrode used for lithium-ion batteries in this embodiment consists of a conductive current collector layer and an active layer coated on the conductive current collector layer. The active layer is composed of a silicon active material, a conductive agent and a binder, the porosity of the active layer is 10% to 60%, the average pore diameter is 1nm to 5μm, and the thickness is 0.5 to 200μm, and the silicon active material accounts for 5% to 85% of the total weight of the active layer, so The conductive agent described above accounts for 4% to 70% of the total weight of the active layer, and the binder accounts for 1% to 35% of the total weight of the active layer; the conductive current collector layer is metal copper foil, and the thickness of the metal copper foil is 10 to 35%. 100 μm.

specific Embodiment approach 2

[0015] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the silicon active material is one or a mixture of silicon powder, silicon nanowires, and silicon nanotubes, and the particle size of the silicon powder is 10nm-20μm; the diameter of the silicon nanowire is 10-1000nm, and the length is 1-50μm; the diameter of the silicon nanotube is 10-1000nm, and the length is 1-50μm. Others are the same as in the first embodiment.

[0016] When the silicon active material described in this embodiment is a mixture, each component is in an arbitrary ratio.

specific Embodiment approach 3

[0017] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the conductive agent is copper powder, aluminum powder, nickel powder, copper fiber, aluminum fiber, nickel fiber, acetylene black, carbon black, artificial One or a mixture of graphite, natural graphite, carbon nanotubes and carbon nanofibers. Others are the same as those in the first or second embodiment.

[0018] In this embodiment, when the conductive agent is a mixture, each component is in an arbitrary ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com