Normal temperature bonding technology-based microminiature fuel cell encapsulation method

A packaging method and fuel cell technology, which can be applied in fuel cells, fuel cell components, and microstructure technology, etc., can solve problems such as increasing the difficulty of packaging operations, affecting cell performance and reliability, and polluting fuel cell membrane electrodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] The present invention will be further described below in conjunction with accompanying drawing:

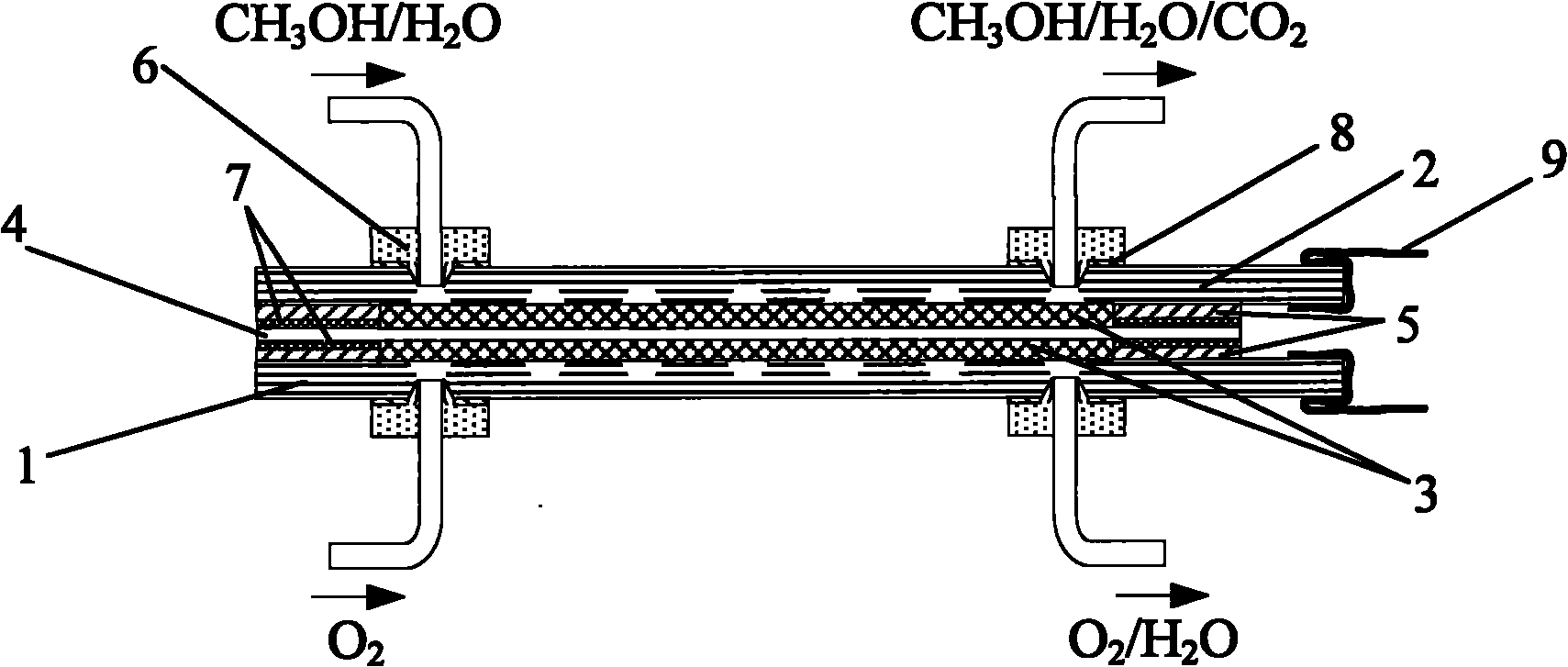

[0069] Such as figure 1 Shown is a schematic diagram of the structure of a micro fuel cell packaged without a clamp. The micro fuel cell has a sandwich structure inside, including a cathode plate 1, an anode plate 2, a flow field sealing gasket 5 and a membrane between the two plates The electrode, the cathode plate and the anode plate are the front side near the membrane electrode, and the back side is the back side. The front side includes micro channels for fuel transmission and a patterned metal layer for drawing current. The membrane electrode is made of carbon paper 3 consists of anode carbon paper, cathode carbon paper and proton exchange membrane 4. A cathode catalyst is loaded on the cathode side of the proton exchange membrane, and an anode catalyst is loaded on the anode side.

[0070] The micro fuel cell described above is packaged by a packaging method based ...

Embodiment 2

[0118] The present invention will be further described below in conjunction with accompanying drawing:

[0119] Such as figure 1 Shown is a schematic diagram of the structure of a micro fuel cell packaged without a clamp. The micro fuel cell has a sandwich structure inside, including a cathode plate 1, an anode plate 2, a flow field sealing gasket 5 and a membrane between the two plates The electrode, the cathode plate and the anode plate are the front side near the membrane electrode, and the back side is the back side. The front side includes micro channels for fuel transmission and a patterned metal layer for drawing current. The membrane electrode is made of carbon paper 3 consists of anode carbon paper, cathode carbon paper and proton exchange membrane 4. A cathode catalyst is loaded on the cathode side of the proton exchange membrane, and an anode catalyst is loaded on the anode side.

[0120] The micro fuel cell described above is packaged by a packaging method based ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com