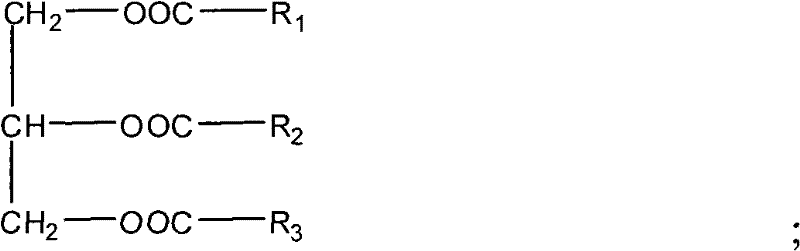

Composite of vegetable insulating oil and modified nano powder and application and preparation method thereof

A vegetable insulating oil and nano-powder technology, applied in insulators, organic liquid insulators, organic insulators, etc., can solve the problems of high viscosity and poor heat dissipation performance of vegetable insulating oil, achieve good physical and chemical and dielectric properties, and enhance heat dissipation. , the effect of improving the dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

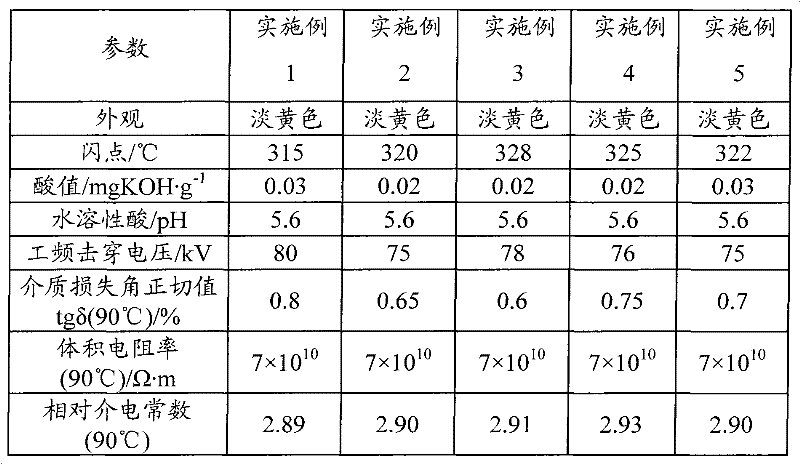

Embodiment 1

[0044] (1) Fe with a diameter of about 40nm 3 o 4 (Ferric oxide) nano-powder is surface-treated. In the treatment step, the quality of adding oleic acid is 1% of the mass of the nano-powder. Ultrasonic dispersion is carried out at 50°C in a water bath while mechanical stirring is carried out. The reaction time is 1.5 hours. Hour;

[0045] (2) The dewatered and degassed vegetable insulating oil and the surface-treated Fe 3 o 4 The nanometer powders are mixed together, and the quality of the nanometer powders is 0.1% of the quality of the vegetable insulating oil.

[0046] (3) The mixed mixture is processed by ultrasonic oscillation, the ultrasonic frequency is 40kHz, the power density is 18W / cm2, the ultrasonic oscillation temperature is 50°C, and the oscillation time is 60min.

[0047] (4) Put the shaken mixture into a planetary ball mill, and use wet grinding method for processing, the rotation speed is 150r / min, and the processing time is 30min.

[0048] (5) Carry out v...

Embodiment 2

[0050] (1) Surface treatment is performed on AlN (aluminum nitride) nanopowders with a diameter of about 100nm. In the treatment step, the quality of dropping oleic acid is 4% of the mass of nanopowders, and then the mixed solution is placed in a water bath at 60°C. Ultrasonic dispersion, mechanical stirring at the same time, the reaction time is 2 hours;

[0051] (2) Mixing the dewatered and degassed vegetable insulating oil and the surface-treated AlN nanometer powder, where the quality of the nanometer powder is 0.01% of that of the vegetable insulating oil.

[0052] (3) The mixed mixture is treated by ultrasonic oscillation, the ultrasonic frequency is 40kHz, the power density is 18W / cm2, the ultrasonic oscillation temperature is 60°C, and the oscillation time is 30min.

[0053] (4) Add the shaken mixture into a planetary ball mill, and use a wet grinding method for processing, with a rotation speed of 150 r / min and a processing time of 60 min.

[0054] (5) Carry out vacu...

Embodiment 3

[0056] (1) Al with a diameter of about 600nm 2 o 3 (Al2O3) nano-powder is subjected to surface treatment. In the treatment step, the mass of oleic acid added is 10% of the mass of the nano-powder, and the mixed solution is ultrasonically dispersed in a water bath at 50° C., and the reaction time is 3 hours.

[0057] (2) The dehydrated and degassed vegetable insulating oil and the surface-treated Al 2 o 3 The nanometer powders are mixed together, and the quality of the nanometer powders is 0.5% of the quality of the vegetable insulating oil.

[0058] (3) The mixed mixture is processed by ultrasonic oscillation, the ultrasonic frequency is 40kHz, the power density is 18W / cm2, the ultrasonic oscillation temperature is 50°C, and the oscillation time is 20min.

[0059] (4) Add the shaken mixture into a planetary ball mill, and use a wet grinding method for processing, with a rotation speed of 150 r / min and a processing time of 60 min.

[0060] (5) Vacuum drying and vacuum degas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com