Health preserving milk containing black bean small peptide, black nice and black sesame seed and preparation process thereof

A preparation process, black sesame technology, applied in the direction of milk preparations, dairy products, applications, etc., can solve the problem of destroying protein quaternary and tertiary structures, product quality control, and fermentation process parameter control. A variety of anti-nutritional factors and other issues, to achieve the effects of simple and easy processing methods, improved disease resistance, and better product taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

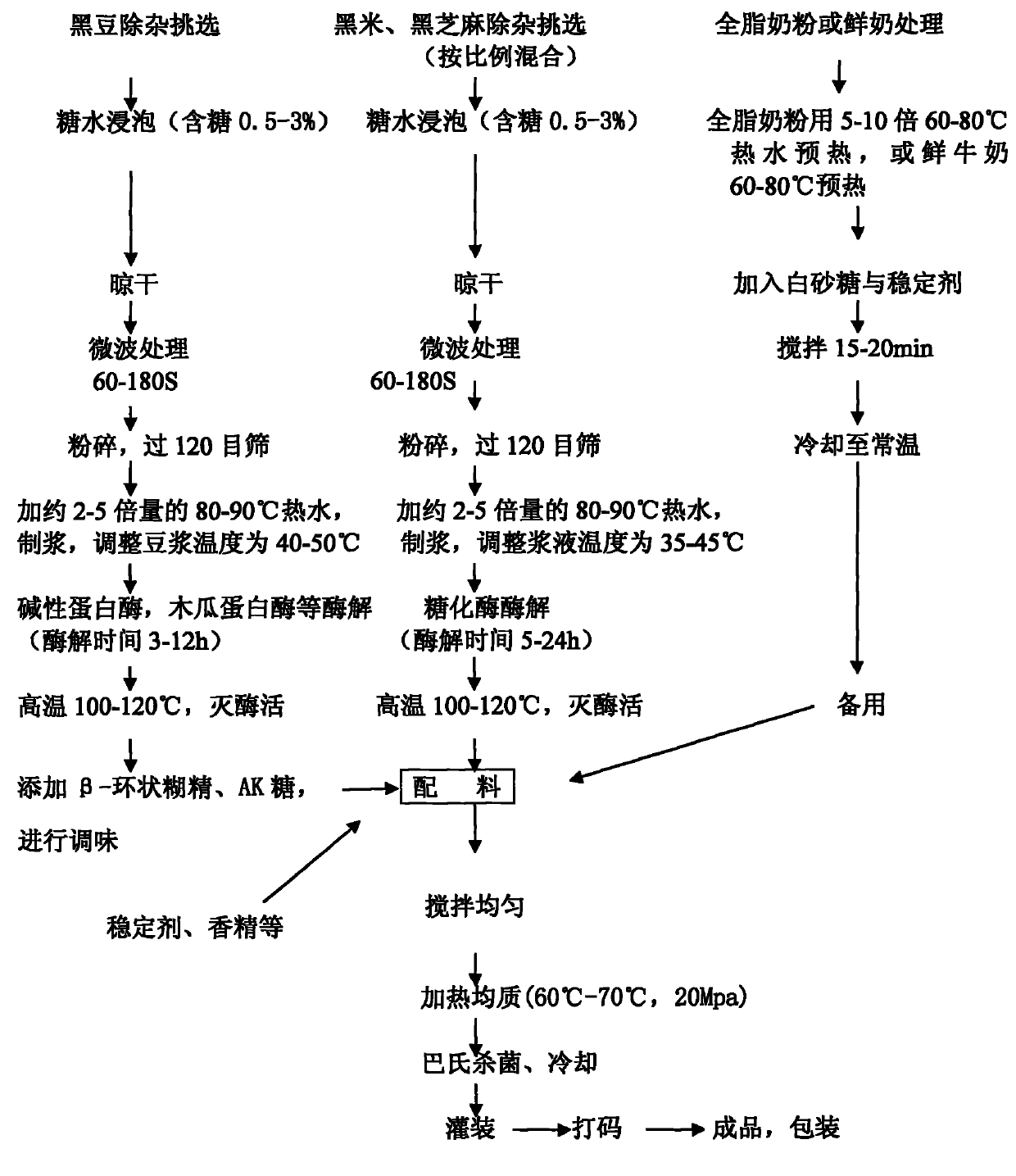

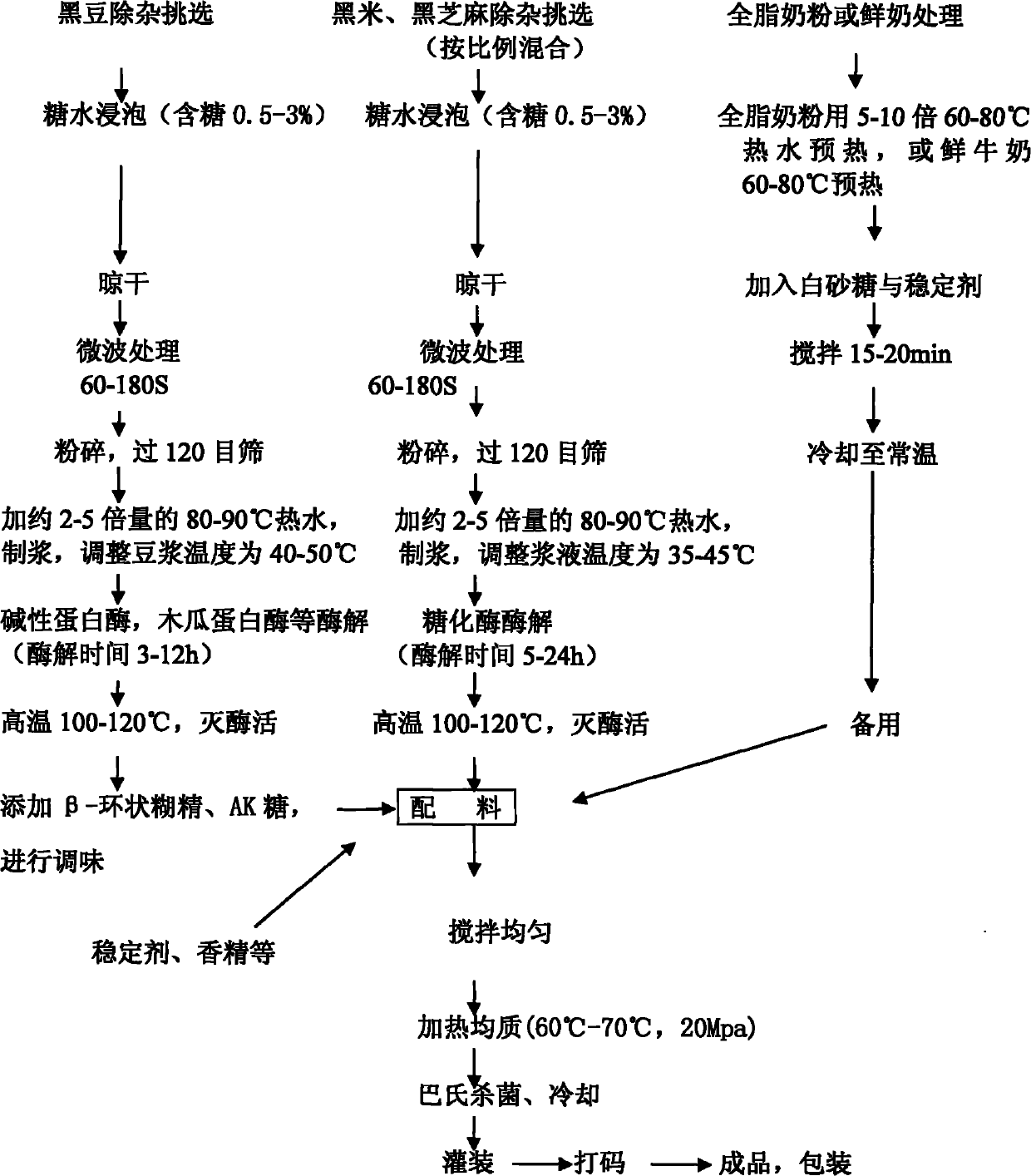

[0032] see figure 1 , black bean small peptide, black rice, black sesame health milk and its preparation process include the following steps:

[0033] a, the preparation method of black soybean small peptide

[0034] Select black beans with full grains, remove impurities, soak in 1% sugar water for 16 hours at room temperature, dry in the air, microwave dry, microwave output power: ≥45KW (adjustable); input apparent power: ≤30KWA; working voltage : Three-phase 380V±10%; Microwave operating frequency: 2450MHz±50Hz; Microwave processing time is 180 seconds. Crush, sieve through a 120-mesh sieve to obtain black soybean powder, add 2 times the amount of hot water at 80-90°C to the black soybean powder, stir until uniform, and make black soybean milk; adjust the temperature of soybean milk to 40-50°C, according to the ratio of enzyme to black soybean milk Add alkaline protease (commercially available) at 500U / g, enzymolysis treatment for 3 hours, high temperature 100-120°C, inact...

Embodiment 2

[0044] see figure 1 , black bean small peptide, black rice, black sesame health milk and its preparation process include the following steps:

[0045] a, the preparation method of black soybean small peptide

[0046] Select black beans with full grains, remove impurities, soak in 3% sugar water for 24 hours at room temperature, dry in the air, microwave dry, microwave output power: ≥45KW (adjustable); input apparent power: ≤30KWA; working voltage : Three-phase 380V±10%; Microwave operating frequency: 2450MHz±50Hz; Microwave processing time is 180 seconds. Crush, sieve through 120 mesh to get black soybean powder, add 5 times the amount of hot water at 80-90°C to the black soybean powder, stir until uniform, and make black soybean milk; adjust the temperature of soybean milk to 40-50°C, according to the ratio of enzyme to black soybean milk Add alkaline protease (commercially available) at 1000U / g, enzymolysis treatment for 12h, high temperature 100-120°C, inactivate the enzy...

Embodiment 3

[0055] see figure 1 , black bean small peptide, black rice, black sesame health milk and its preparation process include the following steps:

[0056] a, the preparation method of black soybean small peptide

[0057] Select black beans with full grains, remove impurities, soak in 0.5% sugar water for 8 hours at room temperature, dry, microwave dry, microwave output power: ≥45KW (adjustable); input apparent power: ≤30KWA; working voltage : Three-phase 380V±10%; Microwave operating frequency: 2450MHz±50Hz; Microwave processing time is 180 seconds. Crush, sieve through a 120-mesh sieve to obtain black soybean powder, add 2 times the amount of hot water at 80-90°C to the black soybean powder, stir until uniform, and make black soybean milk; adjust the temperature of soybean milk to 40-50°C, according to the ratio of enzyme to black soybean milk Add alkaline protease (commercially available) at 800U / g, enzymolysis treatment for 6 hours, high temperature 100-120°C, inactivate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com