Method for preparing aluminum oxide-based ceramic hollow fibrous membrane

An alumina, fiber membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of reduced gas permeability, unable to meet the requirements of practical applications, low mechanical properties, etc., and achieve mechanical strength. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

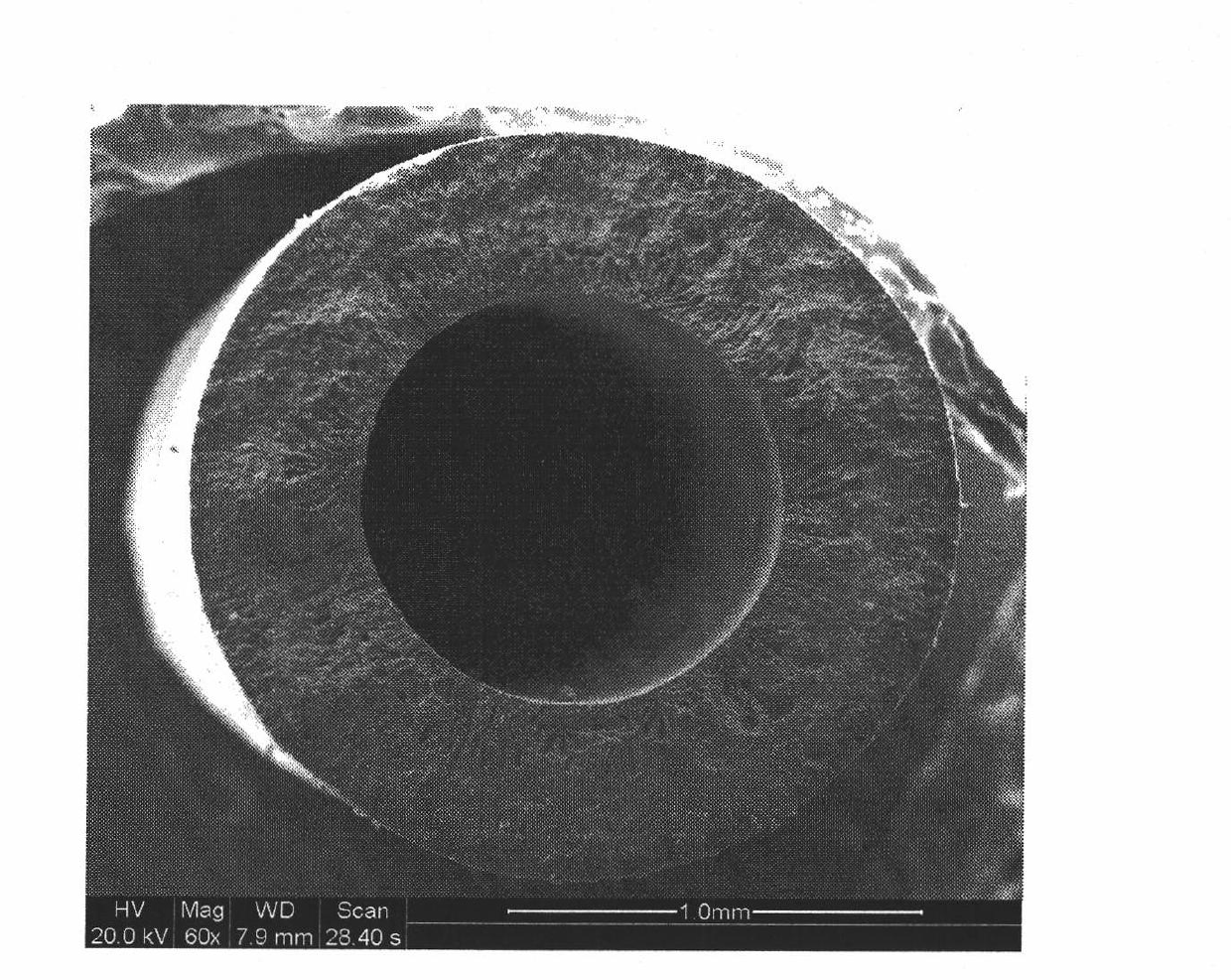

[0021] According to the following steps: (1) mixing of main membrane material and reinforcing agent, (2) preparation of spinning solution, (3) spinning of membrane green body and sintering treatment to prepare reinforced alumina-based hollow fiber membrane, wherein:

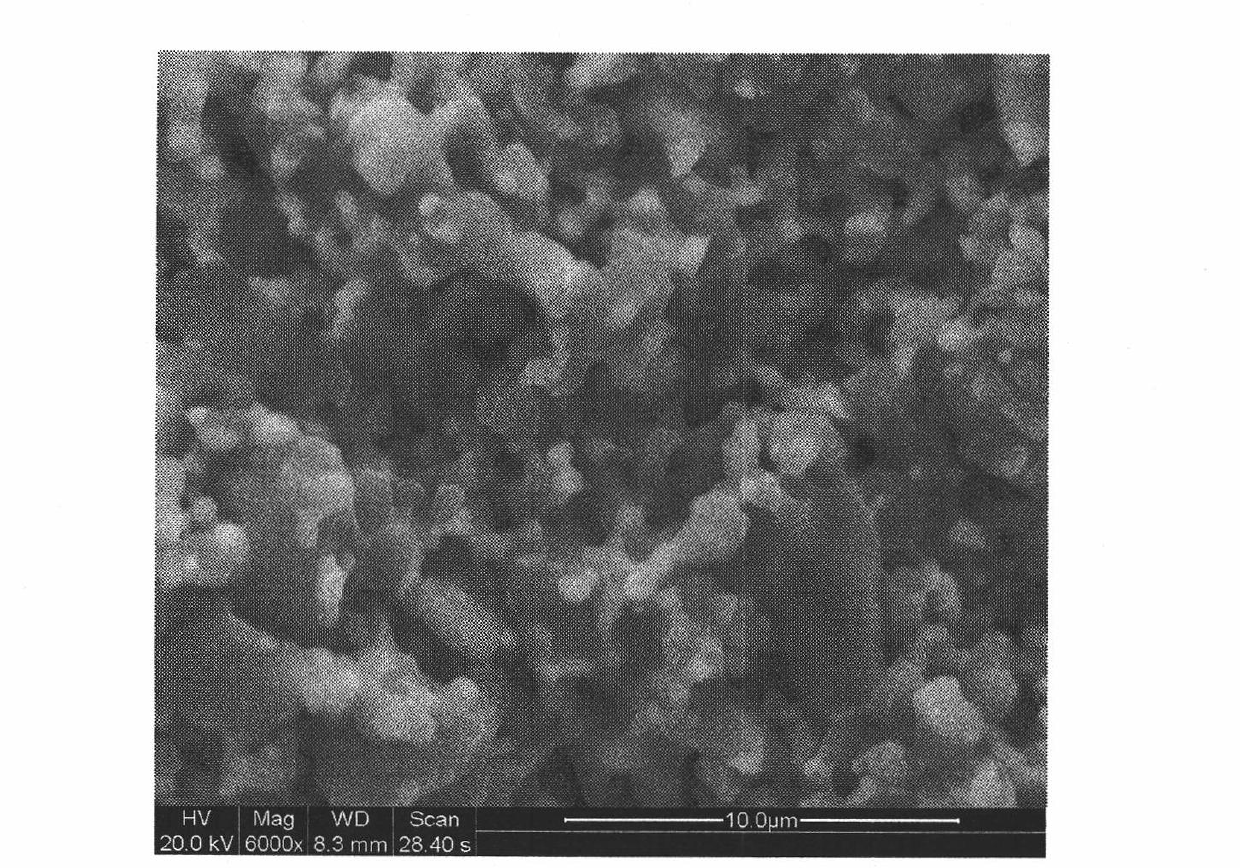

[0022] (1) Mixing of main membrane material and reinforcing agent 350g main membrane material alumina powder (d 50 =5μm) and 150g enhancer magnesium oxide (d 50 = 100nm) for mixing, wet ball milling and mixing for 12 hours, then dry and grind through a 200-mesh sieve.

[0023] (2) Preparation of spinning solution Add 100g polysulfone to 400g N, N-dimethylacetamide to form a polymer solution, then add 500g of mixed ceramic powder prepared in the previous step and stir for 24 hours to obtain uniform dispersion spinning solution.

[0024] (3) Textile membrane green body and sintering treatment Spinning solution is extruded from the spinneret after degassing treatment, enters the external coagulation bath at 30°C t...

Embodiment 2

[0027] According to the steps in Example 1, the film-making solution is prepared and processed by spinning and sintering, but the difference is that aluminum oxide adopts d 50 = 0.5μm powder, enhancer is d 50=10nm magnesium oxide (mass fraction in the mixed ceramic powder is 5%), the mixed powder was wet ball milled for 24 hours, and dried and ground through a 300-mesh sieve. The polymer is cellulose acetate, its mass fraction in the polymer solution is 10%, and the organic solvent is dimethyl sulfoxide. The mixed ceramic powder (the mass fraction in the spinning solution is 30%) was added into the polymer solution and stirred for 48 hours to obtain a spinning solution. The dry spinning distance of spinning is 20cm, the temperature of the external coagulation bath and the core liquid are both 10°C, and the solidification time of the green film is 10 hours. The green film was soaked in tap water at 10°C for 48 hours. During the sintering process, the temperature was raised t...

Embodiment 3

[0029] According to the steps in Example 1, the film-making solution is prepared and processed by spinning and sintering, but the difference is that aluminum oxide adopts d 50 = 20μm powder, enhancer is d 50 =50nm silicon carbide (mass fraction in the mixed ceramic powder is 50%), the mixed powder was wet ball milled for 20 hours, dried and ground and sieved. The polymer is a mixture of polyethersulfone and cellulose acetate, the mass ratio of the two is 3:1, and its mass fraction in the polymer solution is 40%; the organic solvent is N, N-dimethylacetamide and N- A mixture of methyl-2-pyrrolidone, the mass ratio of the two is 1:1. The mixed ceramic powder (the mass fraction in the spinning solution is 80%) was added into the polymer solution and stirred for 30 hours to obtain a spinning solution. The dry spinning distance of spinning is 10 cm, the temperature of the external coagulation bath and the core liquid are both 20° C., and the solidification time of the green film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com