Covalent functionalization graphene and preparation method thereof

A functionalized graphene technology, applied in the field of covalent functionalized graphene and its preparation, to achieve the effects of improved processing performance, improved dispersibility, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the covalently functionalized graphene is: add 1 weight part of graphene oxide and 0.1 to 100 weight parts of azide-containing substances in a reactor, and react for 0.1 to 72 hours, after suction filtration, centrifugation and washing, the covalently functionalized graphene was obtained.

[0032] Described graphene oxide is selected from using concentrated H 2 SO 4 / KMnO 4 , concentrated HNO 3 / Concentrated H 2 SO 4 / KClO 3 , or concentrated HNO 3 / NaClO 3 Graphene oxide made from graphite oxide.

[0033] The azide-containing substance is selected from an azide-containing compound or a mixture of compounds, wherein the structural formula of the azide-containing compound is:

[0034] N 3 -R 1 -R 2 -R 3 ,in,

[0035] R 1 Straight chain or branched alkyl, cycloalkyl, alkoxy, alkylamino, alkamide, alkyl ester, alkanone, alkyl dithio, alkyl silyl, alkyl phosphate group selected from C1-C100 , Fluoroalkyl, pyridyl, substituted pyrid...

Embodiment 1

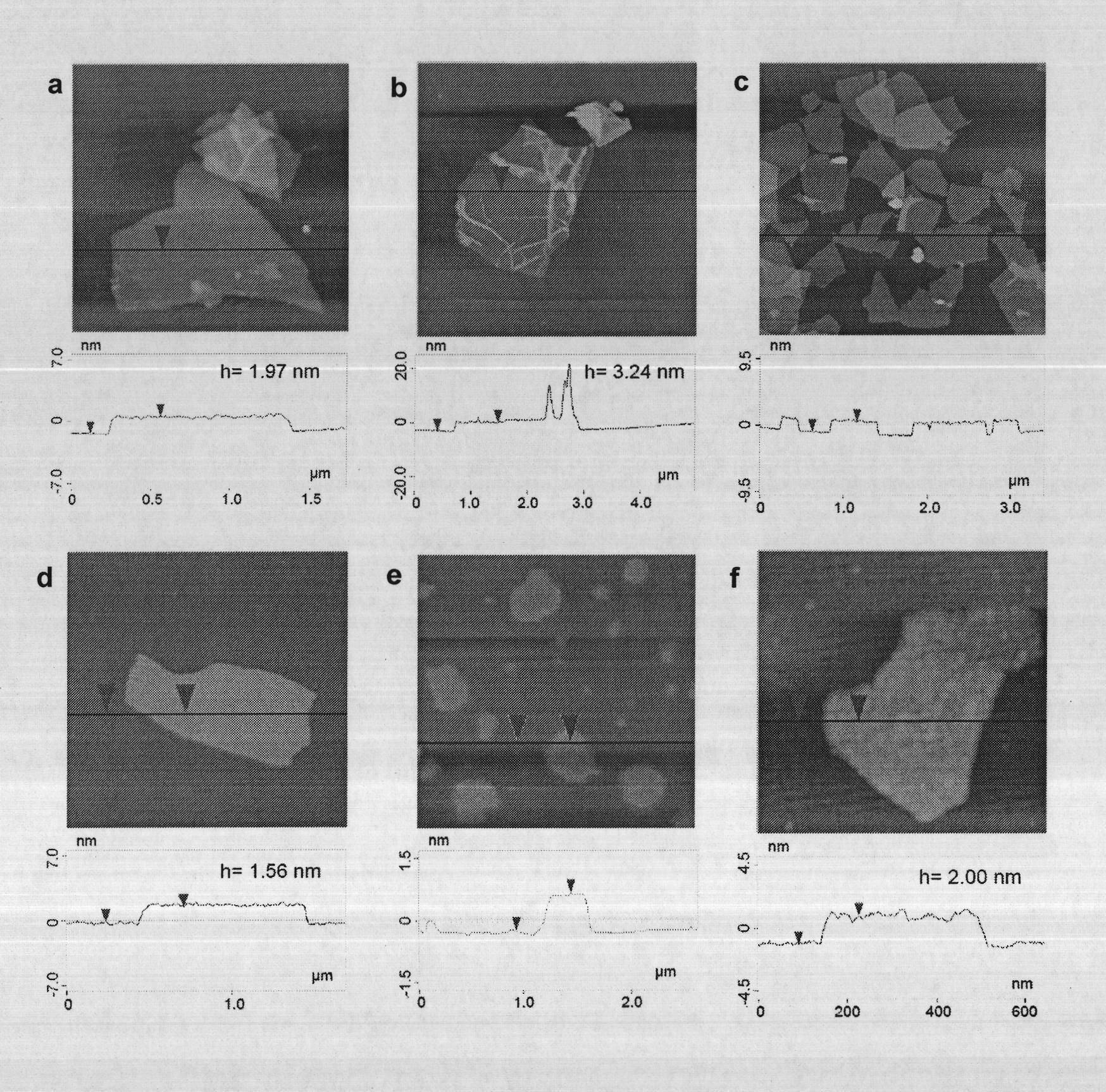

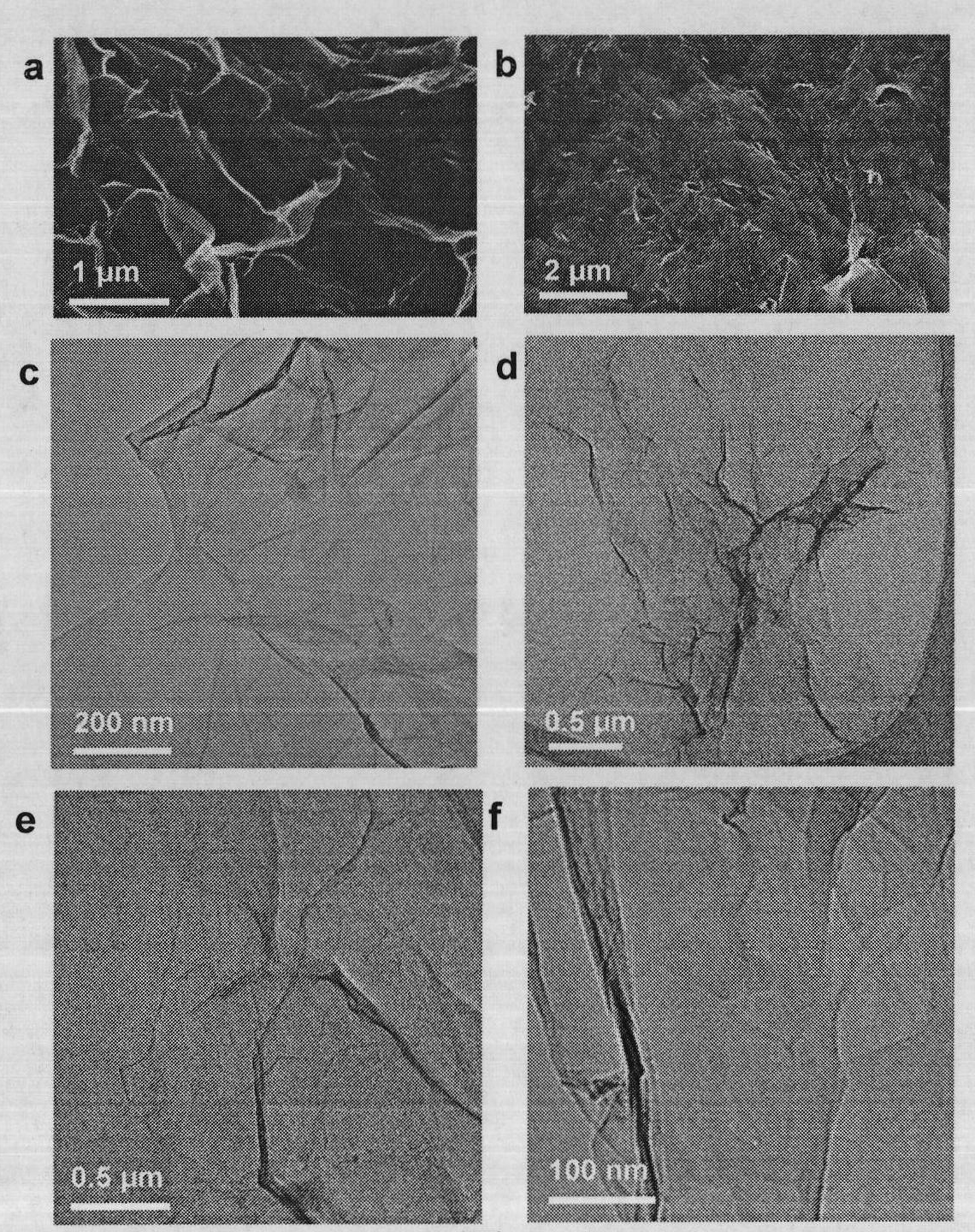

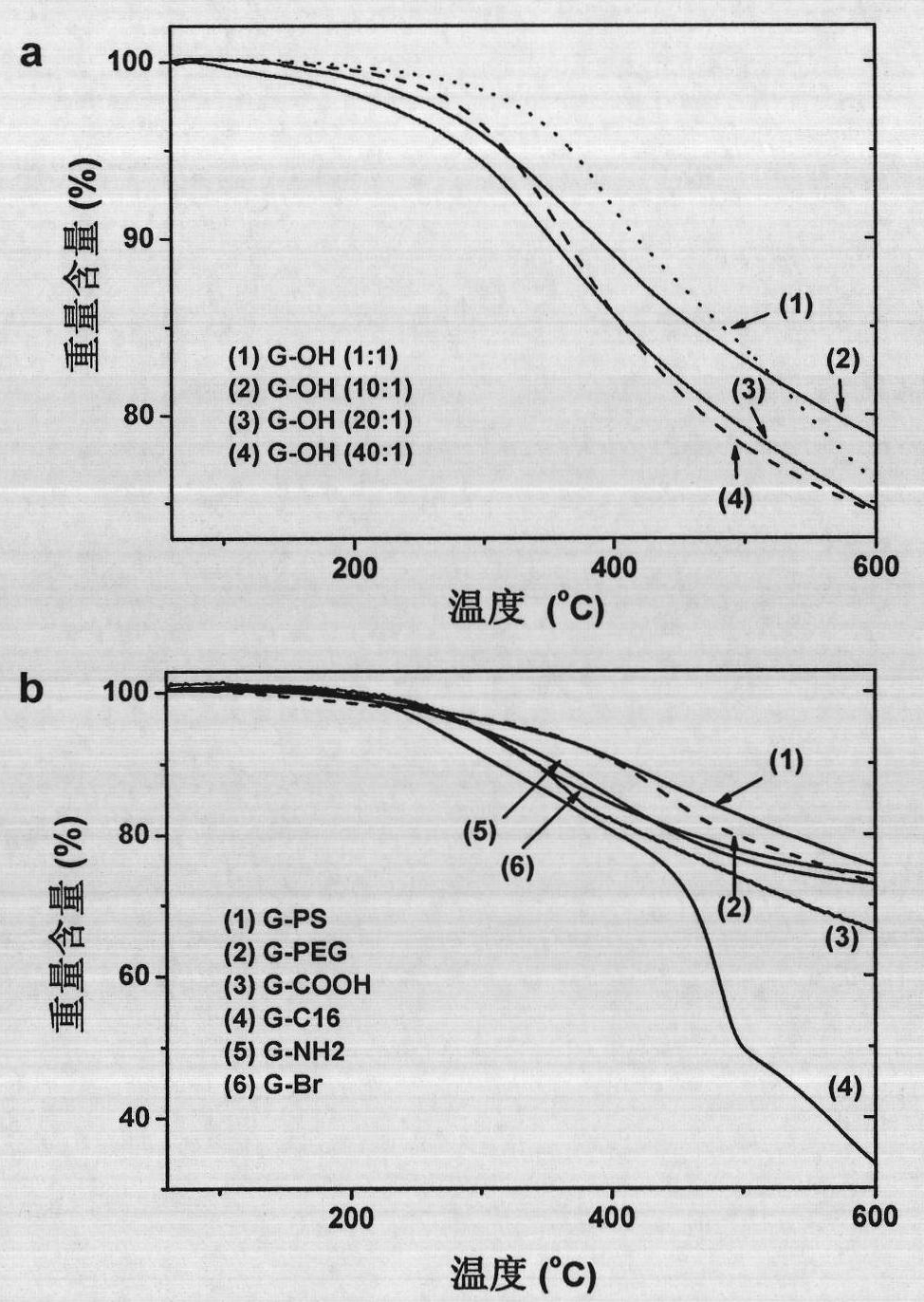

[0040] Take KMnO 4 / Concentrated H 2 SO 4 Graphene oxide prepared by oxidation is used as the initial raw material, and reacted with azide-based compounds such as 2-azidoethanol to obtain hydroxyl-containing graphene. Add 50 mg of graphene oxide and 20 mL of N-methylpyrrolidone into a 50 mL three-neck round bottom flask equipped with a magnetic stirring rotor, add 1 g of 2-azidoethanol into the reaction flask, heat to 160 ° C, and react for 18 hour, after suction filtration or centrifugation, wash with acetone and N, N-dimethylformamide, obtain the functionalized graphene containing hydroxyl, thermal analysis shows that the organic components connected reach 20.9% (functionalized graphene containing hydroxyl) A scanning electron microscope image of graphene is shown in figure 2 a, the thermal weight loss curve is shown in image 3 a Curve 3, X-ray photoelectron spectroscopy see Figure 4 b, solubility photo see Figure 5 a and 5b).

Embodiment 2

[0042] Using the same reaction steps as in Example 1, using graphene oxide as the initial raw material, reacting with azido compounds such as 3-azidopropylamine to obtain functionalized graphene containing amino groups, thermal analysis shows that the organic components connected reach 23.9 %(the thermogravimetric curve figure of functionalized graphene containing amino group sees image 3 b Curve 5, X-ray photoelectron spectroscopy see Figure 4 c).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com