Method for processing sols of alumina refractory particles

A technology of refractory material and treatment method, which is applied in the treatment of high-aluminum refractory material particles and the field of sol treatment of aluminum refractory material particles, can solve the problem of low temperature coating of refractory material particles and low temperature treatment process without mentioning precursors. problems, to achieve the effect of promoting sintering, solving the bottleneck of agglomeration, and reducing the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

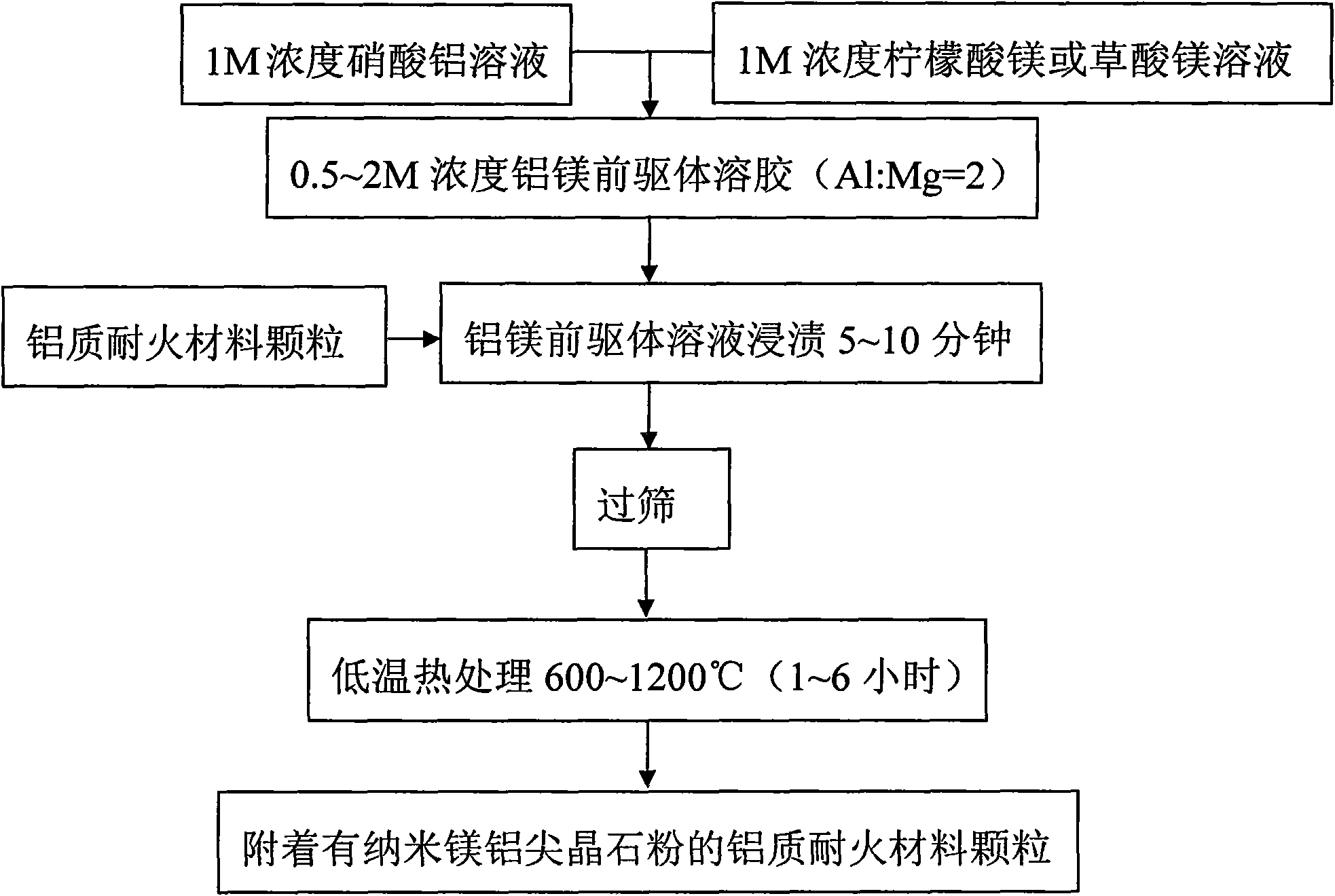

[0026] Embodiment 1, comprises the steps:

[0027] The first step is to configure the precursor Al-Mg sol.

[0028] Using aluminum nitrate as aluminum source, magnesium citrate as magnesium source, according to magnesium aluminum spinel MgAl 2 o 4 In a chemical formula with a ratio of aluminum to magnesium of 2, a mixed sol of nitrate and citrate aluminum-magnesium precursors with a molar concentration of 0.5M was prepared.

[0029] In the second step, the aluminum refractory particles, such as sintered magnesia-aluminum spinel particles, are immersed in the nitrate and citrate aluminum-magnesium precursor sol for 5 minutes, and then taken out and sieved to make the impregnating solution and the particles separate. The aluminum refractory material adopts sintered magnesia-aluminum spinel or fused magnesia-aluminum spinel or sintered corundum or fused corundum.

[0030] The third step is to carry out low-temperature treatment on the impregnated aluminum refractory particles...

Embodiment 2

[0031] Embodiment 2, comprises the steps:

[0032] In the first step, aluminum nitrate is used as aluminum source, magnesium citrate is used as magnesium source, according to magnesium aluminum spinel MgAl 2 o 4 In a chemical formula with a ratio of aluminum to magnesium of 2, a mixed sol of nitrate and citrate aluminum-magnesium precursors with a molar concentration of 2M is prepared.

[0033] In the second step, the aluminum refractory particles, such as fused magnesia-aluminum spinel particles, are immersed in the mixed sol of nitrate and citrate aluminum-magnesium precursors for 10 minutes, and then taken out and sieved to make the impregnation solution and the particles separate.

[0034] The third step is to perform low-temperature treatment on the impregnated aluminum refractory particles, that is, place the sieved particles in a sagger for 3 hours at 1000°C, and react and synthesize on the aluminum refractory particles to obtain nano-magnesium-aluminum tips The spar...

Embodiment 3

[0035] Embodiment 3, comprises the steps:

[0036] In the first step, aluminum nitrate is used as aluminum source, magnesium citrate is used as magnesium source, and magnesium aluminum spinel MgAl 2 o 4 In a chemical formula with a ratio of aluminum to magnesium of 2, a mixed sol of nitrate and citrate aluminum-magnesium precursors with a molar concentration of 1M was prepared.

[0037] In the second step, aluminum refractory particles, such as sintered corundum particles, are immersed in the mixed sol of nitrate and citrate aluminum-magnesium precursors for 8 minutes, and then taken out and sieved to separate the impregnation solution from the particles.

[0038] The third step is to perform low-temperature treatment on the impregnated sintered corundum particles, that is, place the sieved particles in a sagger for 1 hour at 1200°C, and synthesize them on the aluminum refractory particles to obtain nano-magnesium-aluminum spinel powder , the raw material of sintered corundu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com